|

ROUTING: Achieving Premium Finishes When Routing Acrylic

Routing of acrylic has become one the most popular

methods of plastic fabrication in the sign and

point-of-purchase industries. As the accuracy of

CNC routers continues to improve, additional gains are

being made into the machine building, medical devices and

valve industries. A common quality across all of these

industry segments is the requirement for a premium finished

edge on acrylic without the need for post-routing finishing

operations. Four factors in the routing operation typically

will affect the quality of the cut edge: Tooling,

Programming, Machine Condition and Fixturing. If any one

of these factors is not optimized, it will be extremely difficult

to maintain a consistent, high-quality edge finish. Two

of the factors - Tooling and Programming - will be covered

in this article and the remaining two in a future article.

Tooling

Tooling is a broad topic, but there are some simple guidelines

that can be used to decrease the likelihood of failure

during cutter selection. The first selection criterion for

router tooling is typically diameter. While it is a common

request for tooling diameters to be in the 1/8” to 1/4”

range, designing the parts, fixtures and programs for 3/8”

to 1/2” tooling can dramatically improve surface finishes

and consistency from job to job. A typical result from

increasing cutting edge diameter from 1/4” to 3/8” can be

a drop in surface finish from 40-60 rms to 18-25 rms. This

is usually accompanied by an increased feed rate as well as

better chip extraction. The stability and flute depth offered

by larger diameter cutting tools cannot be overestimated.

That said, it is important to note that there is typically only

a marginal benefit when increasing cutting edge diameters

over 1/2” as long as the depths of cut are not exceeding 2”.

The price-to-performance ratio cannot typically

support the

use of 5/8” to 1” diameter cutters in sheet stock.

support the

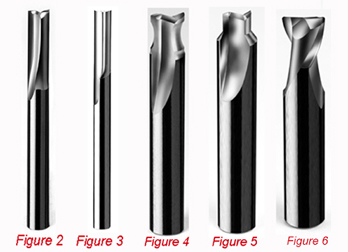

use of 5/8” to 1” diameter cutters in sheet stock. After diameter, cutter configuration is frequently the

second selection criterion for tooling. As a rule of thumb,

the smaller the diameter of cutter that is being used, the

more likely it is that a spiral configuration will yield the

optimum edge finish. While straight flutes typically have

good success in larger diameters (3/8” and above), it is the

spirals that excel when cutting with small diameter tooling.

Single edge spiral O-flutes (see Figure 1) typically give

the best edge finishes in 1/4” and smaller tooling. When

moving into the larger diameters, typically low helix multifluted

tools will yield the best results with some

variations, depending on the manufacturing

method of the acrylic (i.e. cast or extruded) and

any fillers that may have been used. It is also in

these larger diameters that the double edge

straights can typically begin to perform well. Both

V-flute and O-flute configurations have been

shown to work well through testing and industry

use. (see Figures 2 & 3)

A final note on tooling is to mention the existence of numerous specialty tools available in the market today.

There are products that can be used to provide a radiused edge on parts (Figure4), to rout a finished edge and apply a top chamfer at the same time (Figure 5), or to create a smooth bottom

surface during pocketing without the swirling effects

of standard router bit points (Figure 6). These cutters

either solve problems that have been recurrent in the

industry or allow fabricators to eliminate tool change

cycle times and/or utilize machines without tool changers.

There are products that can be used to provide a radiused edge on parts (Figure4), to rout a finished edge and apply a top chamfer at the same time (Figure 5), or to create a smooth bottom

surface during pocketing without the swirling effects

of standard router bit points (Figure 6). These cutters

either solve problems that have been recurrent in the

industry or allow fabricators to eliminate tool change

cycle times and/or utilize machines without tool changers.

Programming

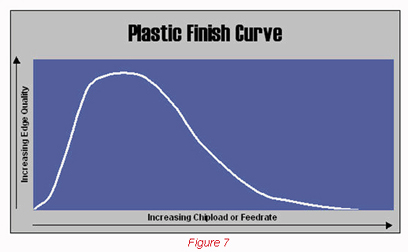

Selecting the right cutting parameters and cutting

methods is extremely important when edge finish is the

primary driving factor of an operation. Every material and

cutter combination has a “sweet spot” in the cutting

parameters and slight deviations in any direction can

cause an unacceptable decrease in surface finish quality.

Feeds and speeds are typically the best known variables

as far as cutting parameters and they are extremely sensitive

to minor variations. Unlike many other commonly

routed materials, plastics, and particularly acrylics, have

an extremely narrow chip load range that can be used to

produce an optimal finish (see Figure 7). Each cutter

(based on configuration and diameter) will have a different

optimum chip load for each material type. As a rule of

thumb, the following feed rates are good starting points if

the goal is optimum edge finish. A constant spindle speed

of 18,000 rpm and a depth of cut equal to the cutter

diameter is assumed.

-

- 1/8” Diameter Tooling: 75-100 ipm

-

- 1/4” Diameter Tooling: 100-200 ipm

-

- 3/8” Diameter Tooling: 125 ipm to

250 ipm

-

- 1/2” Diameter Tooling: 150 ipm to

300 ipm

As long as the router bit is not having

stability problems and the workpiece

is well fixtured, most of these feedrates

can be increased by simply

increasing the spindle rpm. With the

newer generation spindles typically

having maximum speeds of 21,000 to

24,0000 rpm, most of these feed rates

will have plenty of room for improvement.

The only consideration to

remember is that, unlike other materials,

increased spindle speeds must be

accompanied by an increase in feed

rate to remain within that “sweet spot”

on the chipload. Excessive spindle

speeds will typically melt the plastic or

cause a wiping or smearing action on

the finished edge that reduces the

quality of the surface finish.

After feeds and speeds have been

dialed in (usually through manufacturer

recommendations, as trial-and error

is a time- and material-intensive

process), the next step is to choose the

cutting method. Both conventional and climb cutting have their place, but here is the rule of

thumb: Larger diameters almost always perform better in

a conventional cut mode. Smaller diameters are entirely

material-dependent and must be tested to determine the

best method.

Other programming parameters that should be considered

are finish passes, entry points and depths of cut.

Typically smaller diameters are the only tools that require

finish passes for optimum edge finishes. There is usually

only a marginal gain in finish quality for acrylics when 3/8”

and 1/2” tooling is used in a two pass system. The biggest

problem that seems to surface in the industry regarding

finish passes is the amount of material to remove. Many

CNC operators and/or programmers have previous experience

in the metal working industry and that can be a detriment

when attempting to use similar cutting parameters

in acrylic. A typical finish pass in ferrous and non-ferrous

metals can be as little as .004”-.005”. When this amount

of material is removed in acrylic, it frequently will compress

and cause the cutter to actually skip across the surface.

This is due mainly to the high rake angles employed

in plastic tooling and the aggressiveness of their cutting

action. Without at least .015”-.030” of material to

remove, most acrylic router bits will not have enough

material to bite into and will actually show a deteriorated

finished edge over the initial roughing cut.

Entry points can also be a troublesome issue during

programming. While most acrylics do not exhibit the chip

wrap problem prevalent in other softer plastics, their tendency

to craze can sometimes inhibit their ability to be

machined at high speeds during cutter entry. The most

common method is to slow the feed rates down to compensate

for this problem, but a ramped entry can work

equally well and will not show the entry melt that is associated

with direct plunging by router bits. Another issue

on cutter entry is that, because router bits do not have a

centering point similar to drills (this is to allow flat bottom

cutting), they will have a tendency to “walk” during the

plunge. The visible result is a larger entry point than the

routed channel that will follow. The result is somewhat

similar to what a keyhole slot looks like with a large diameter

hole followed by a smaller slot width. Once again

ramped entry can reduce this effect, but it is easier to

enter the cut by plunging into a scrap area and moving to

the final cut path in a lateral direction.

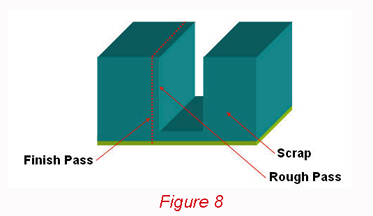

As a final parameter to be considered, depths of cut are

critical to ensuring consistent edge finishes and non-broken

tooling.

A good rule of thumb is a maximum of twice

the cutter diameter per depth of cut. A favorite programming

method is to use multiple depths of cut when cutter

breakage is an issue and then to take a final clean-up pass

of .015” for the entire material thickness. (see Figure 8)

This gives a premium edge finish while preventing broken

tools in the smaller diameters. It is a common concern

that taking finish passes in small parts will cause the parts

to move once they have been cut away from the scrap,

particularly in intricate parts like letters. The best solution

is to use the multiple depth pass/single finish pass method

described above, but to not cut through the paper masking

on the bottom side of parts. This allows the vacuum to

continue holding the parts, while the .015” finish pass will

not typically tear the parts off of the masking.

While much of the information presented above was in

the form of Rules of Thumb, it is essential that only the

proper cutting tools and cutting parameters be used when

machining acrylics. The information presented here is a

broad overview of information regarding routing of acrylics.

The best source of detailed information is typically the tooling

manufacturer’s recommendations either through published

sources or their Technical Services Departments.

A good rule of thumb is a maximum of twice

the cutter diameter per depth of cut. A favorite programming

method is to use multiple depths of cut when cutter

breakage is an issue and then to take a final clean-up pass

of .015” for the entire material thickness. (see Figure 8)

This gives a premium edge finish while preventing broken

tools in the smaller diameters. It is a common concern

that taking finish passes in small parts will cause the parts

to move once they have been cut away from the scrap,

particularly in intricate parts like letters. The best solution

is to use the multiple depth pass/single finish pass method

described above, but to not cut through the paper masking

on the bottom side of parts. This allows the vacuum to

continue holding the parts, while the .015” finish pass will

not typically tear the parts off of the masking.

While much of the information presented above was in

the form of Rules of Thumb, it is essential that only the

proper cutting tools and cutting parameters be used when

machining acrylics. The information presented here is a

broad overview of information regarding routing of acrylics.

The best source of detailed information is typically the tooling

manufacturer’s recommendations either through published

sources or their Technical Services Departments.

Van Niser is Director of Plastic Application Engineering

at Onsrud Cutter. Readers are invited to send questions to

Van Niser at Onsrud Cutter, 800 Liberty Drive,

Libertyville, IL 60048, E-mail: vniser@onsrud.com.

For more information, click on the author biography at the top of this page.

|