|

IWF New Products

The International Woodworking Fair (IWF) held in

Atlanta, Georgia August 26-29, 2004 hosted buyers

from 43 states and 46 countries. Over 42,000 attendees

browsed 1,372 exhibits, many featuring exciting new

products. Following is an overview of some of the products

we found that are well suited for the needs of plastic distributors

and fabricators.

MACHINERY

Tilting Table Diamond Edge Polisher

A.W.E.D. introduced

the Bermaq

AMT Table Top Model

Edge Polisher.

The

unit features an endless

woven feed belt

which transports the

part past the fixed

cutter head. With

capacity of 1 3/8”

thick, a four roller

hold down clamp

maintains the part against the cutter and fence giving a

smooth and vibration free transparent

polished edge.

The

unit features an endless

woven feed belt

which transports the

part past the fixed

cutter head. With

capacity of 1 3/8”

thick, a four roller

hold down clamp

maintains the part against the cutter and fence giving a

smooth and vibration free transparent

polished edge.

The heavy duty construction

assures trouble free performance. It

comes complete with one cutter with

replaceable tips from PCD to Natural

Diamond.

The tilting table has pre-set stops

at 15, 22, 30 and 45 degrees with

endless stops in between.

For additional information, contact

Victor Miranda, A.W.E.D. Corp.,

1175 Buford Highway, Suite 101,

P.O. Box 1756, Suwanee, GA 30024,

770-831-9800, Fax: 770-831-7404,

E-mail: awedmachin@aol.com, Web:

www.awed-machine.com.

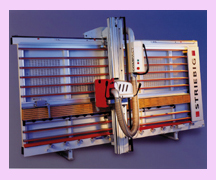

Compact Precision

Panel Saw

A redesigned vertical panel saw

now available from Colonial Saw

offers improved

precision and convenience

over previous models.

precision and convenience

over previous models. The

Swiss-made Striebig COMPACT is

the only saw of its kind to feature

standard aluminum fingers that can

be moved individually along the horizontal

T-slotted center shelf bar to

customize the saw. For greater comfort

when sawing

small panels,

workpiece

support is provided

along the

full length of

the saw. Other

user-friendly

improvements

include a shifting

grid that

moves upward so that it can’t be jammed or damaged by

off-cuts leaning against the frame, a 24” repetitive rip

device with a roller follower and a measuring stop that

flips out of the way.

The new COMPACT is a freestanding, rigid unit that can

handle sheets up to 5’ x 10’. It cuts perfect, repeatable

edges on particleboard, acrylic, composite, plastic and

non-ferrous-metal panels. There is additional dust extraction

and a new plunge-handle “telescopes” to facilitate the

ripping of tall panels. Other performance-enhancing features

include heavy-duty support rollers and adjustable

cutting depth.

Improved digital measuring systems provide increased

accuracy and convenience. The X-axis system permits fine

adjustment for accuracy to 1/10 mm and has a long-life

battery. The Y-axis system allows toggle-switch referencing

from the saw’s rollers or center shelf. Other options

include a scoring saw unit, grooving accessories and an

angle-cutting unit. All components are UL/CSA approved.

For additional information, contact David Bull, Colonial

Saw, Inc. 122 Pembroke Street, P.O. Box A, Kingston, MA

02364, 781-585-4364, Fax: 781-585-9375, E-mail:

info@csaw.com, Web: www.csaw.com.

CNC Router Line

FlexiCAM has developed the Barracuda line of

machines which continues their tradition of speed, ease of

use and reliability in 3D machining. What they developed

was a Z-axis drive system that is faster, more reliable and

offers more clearance than

conventional systems used

on most routers.

With this

design, more clearance is

created for the

parts beneath

the gantry and

less weight has

to be moved up

and down, allowing

you to machine thicker

parts than ever before,

faster. The Z-axis is designed with high quality ball screw,

to aid in achieving maximum speed and precision. This

Barracuda is great for sign making, woodworking and

plastic cutting, and many other applications, all in a small

foot print. The Barracuda is offered in 6 models and sizes

from 4’ x 4’ to 8 1/2’ x 10’.

FlexiCAM also has a Pro Series that was specifically

designed for demanding customers from various industries

such as signmaking, neon fabrication, acrylic and

plastic fabrication or solid wood working. Extensive components

are available for this series, including the High

Performance Turbo option. The Pro Series is offered in 11

models and sizes from 61” x 61” to 100” x 242”.

For additional information, contact Jon Dickson,

FlexiCAM, 555 Burrard Street, Suite 900, Vancouver, BC

Canada V7X 1M9, 604-893-7017, Fax: 604-608-2904,

E-mail: jdickson@flexicam.com, Web: www.flexicam.ca.

Panel Saw With Infeed System

Holzma offers the HPP 380P Optimat panel saw for

plastics with TBP-200 infeed system.

The TBP-200 is CNC

controlled and features vacuum pick-up and five panel

storage positions, each capable of holding over fifty sheets

of different materials. This combination of machine and

material handling equipment is designed for speed and

efficiency, avoiding time lost to material changeovers.Equipped with a 28HP variable speed main saw

motor, the saw has the power for quick, accurate

cutting of the densest plastics and composites and

the flexibility to provide the optimal saw blade rim

speed to achieve outstanding edge quality for each

material. Contributing to ease of operation for the

HPP 380P is Holzma’s unique touch-free magnetic

measuring system, automatic cutting height and

length, automatic side pressure device placement,

replaceable wear surface on the machine bed and

the absence of exposed lubricated parts which, if

present, can attract and hold abrasive dust, causing

premature wear. The Windows XP-based

Cadmatic 4.0 control with its detailed, 3D graphics

simplifies operator training and provides detailed

prompts throughout the cutting process to help the

operator be productive.

For additional information, contact Bill Pitt,

Holzma U.S., 1200 Tulip Drive Gastonia, NC

28052, 704-861-8239, Fax: 704-867-4140

E-mail: bpitt@stilesmachinery.com, Web: www.

stilesmachinery.com.

Traveling Gantry CNC

Komo Machine introduced the new Solution

Traveling Gantry CNC Machining Center. The

Solution series has been developed specifically for

the cost-conscious yet demanding customer who

expects the utmost in technical quality and reliability.

These machines feature a moving gantry

configuration with table sizes available to 50’ in

the X axis, and utilize the exclusive Komo-GE

Fanuc Panel i control with HVI servo system and

integrated Windows®-based PC.

These machines feature a moving gantry

configuration with table sizes available to 50’ in

the X axis, and utilize the exclusive Komo-GE

Fanuc Panel i control with HVI servo system and

integrated Windows®-based PC.

Standard features

include

a four-pole

HSK 63F

spindle, 10 pocket automatic toolchanger with aggregate capability

and a universal grid fixture table. A nine-spindle line boring

For additional information, contact Jeff Erickson, Komo

Machine, Inc., 11 Industrial Blvd., Sauk Rapids, MN

56379, 800-643-5089 / 320-252-9887, Fax: 320-656-

2472, E-mail: jerickson@komo.com, Web: www.komo.com.

New Router Lines

MultiCam introduced their new 5000 and 3000 Series

CNC Routers.

The 5000 series is stronger, faster and

heavier then its predecessor, the MG Series. Loaded with

many standard features, the all-steel, moving-gantry

design allows machining of large parts while maintaining

a mid-sized, space-saving footprint.

Designed for a wide

range of applications,

the 5000 Series

machines

are the

perfect

solution

for companies

looking for

high performance in a CNC

router. The series is available in over 40

standard machine sizes from 50” x 50” to 120” x 362”.

The 5000 series is stronger, faster and

heavier then its predecessor, the MG Series. Loaded with

many standard features, the all-steel, moving-gantry

design allows machining of large parts while maintaining

a mid-sized, space-saving footprint.

Designed for a wide

range of applications,

the 5000 Series

machines

are the

perfect

solution

for companies

looking for

high performance in a CNC

router. The series is available in over 40

standard machine sizes from 50” x 50” to 120” x 362”.

MultiCam’s 3000 Series is loaded with standard features.

The all-steel, moving-gantry design allows machining

of large parts while maintaining a small, space-saving

footprint. Designed for a wide range of applications, the

3000 Series machines are the perfect solution for companies

looking for both value and high performance in a

CNC router. Seven standard machine sizes range from 50”

by 50” to 80” x 144”.

For additional information, contact Mark Allen,

MultiCam L.P., P.O. Box 612048, Dallas, TX 75261, 972-

929-4070, Fax: 972-929-4071, E-mail: mark@multicam.

com, Web: www.multicam.com.

Panel Cutting Saws The Original™ Saw Company

introduced two Panel

Cutting Saws.

These rugged

manual panel

sizing cutoff

saws are

capable of a

wide variety

of panel sizing

operations.

These rugged

manual panel

sizing cutoff

saws are

capable of a

wide variety

of panel sizing

operations.

The

machines are constructed

of a heavy welded u-channel frame, a

structural tubing over arm beam, as well as cast iron and cast aluminum assemblies.

Available options include with an electronic power

carriage cross feed system.

Capable of cutoff applications up to an 8” deep,

the saws have a cutoff capacity from 55” to 64”.

Both have Continuous Duty rated motors and controls

with either a 5 hp or 7.5 hp 3 phase motor.

The brakes are automatic electromechanical with a

magnetic starter with 24 volt low voltage controls.

For additional information, contact Allen Eden,

The Original Saw Company, 465 Third Ave. SE, Brit,

IA 50423, 800-733-4063, Fax: 641-843-3869,

E-mail: origsaw@ncn.net, Web: www.originalsaw.com.

Cut From The Bottom Up

Vertical panel saws, traditionally, have the saw

pulled down through the substrate. The saw blade

enters the material from the backside. It then cuts

upward, toward the

facing side. This can

cause “blow out” on

the facing side.

Saw Trax has

incorporated a second

set of material

roller holes in its

fence which allows

the user to cut in an

upward direction.

The new method

gives the saw operator

the option of cutting

from the bottom

of the sheet to the top of the sheet. With this

technique, the saw blade cuts down through the

material, from the facing side to the backside.

roller holes in its

fence which allows

the user to cut in an

upward direction.

The new method

gives the saw operator

the option of cutting

from the bottom

of the sheet to the top of the sheet. With this

technique, the saw blade cuts down through the

material, from the facing side to the backside.

This new method keeps the saw blade from

pulling thinner materials away from the panel

saw frame when cutting. Thin plastics like 1/4”

Lexan® can shatter if pulled away from the cutting

surface. When cutting with this method, the

saw blade pushes the material to the frame while

cutting.

Attaching the material rollers in the upper holes

allows the user to start a cut below the material and

cut upwards while the saw blade cuts down, forcing

the material down. The machine ships from the factory

with the material rollers in the bottom, more

traditional holes.

For additional information, contact Michael Della

Polla, Saw Trax Mfg. Inc., 3790 Highway 92, Suite

200, Acworth, GA 30102, 888-SAW-TRAX / 770-

974-0021, Fax: 770-975- 1618, E-mail: sawtrax@

aol.com, Web: www.sawtrax.com.

High Precision Plastic Panel Saw

Schelling’s FMK panel saw mechanical and other specially engineered materials.

The

FMK provides extremely tight cutting tolerances, chip

free cutting of material as thin as .020” without a cover

board and produces glassy smooth finishes that eliminate

the need for secondary machining.

The

FMK provides extremely tight cutting tolerances, chip

free cutting of material as thin as .020” without a cover

board and produces glassy smooth finishes that eliminate

the need for secondary machining.

Features include: rigid heavy duty construction; stateof-

the-art material handling technology that automates

loading, cutting and off-loading processes; on-line remote

diagnostics for increased uptime and productivity; spindle

speed control combined with a patented blade design;

solid pressure beam with dust protection curtain for dust

free parts; online downloading of optimized cutting patterns

and label printing.

For additional information, contact Stephen Bailey,

Schelling America, Inc., P.O. Box 80367, Raleigh, NC

27623, 919-544-0430, Fax: 919-544-0920, E-mail:

sbailey@schelling.com, Web: www.schelling.com.

High Speed Precision Panel Saw

Designed with plastic distributors and fabricators in

mind, the Sigma 120 PLM panel saw from SCM Group

USA Inc. provides superior cutting quality while reducing

material waste

and improving yield at an affordable price.

and improving yield at an affordable price.

Some of the added value features of the saw include a

4.25” cutting capability; high speed carriage movement

with optimized operation for fast cycle times; a worktable

designed to cut thin materials; powerful 24 hp independent

main motor;

main blade cooling;

mass-balancing

of the saw carriage

to ensure even

wear and a perfect

edge finish;

triple dust conveying

system and a pusher with clamps for quick, accurate

loading and cutting.

Equipped with a Dell personal computer with Cutty

Sheet Optimization Software, this saw guarantees

repeatability and easy operator interface. The SIGMA also

includes a modem connection available for on-line technical

support and many other advanced technology capabilities.

The saw is available in either 10.5” or 14.5” configurations.

For additional information, contact Phil Bryant, SCM

Group USA Inc., 2475 Satellite Blvd., Duluth, GA 30096,

770-813-8818, Fax: 770-813-8819, E-mail: info@

scmgroup-usa.com, Web: www.scmplastics.com.

Increased Speed

ShopBot Tools Inc., a leading manufacturer of affordable

CNC tools, now offers the fastest CNC routers in its

class.

ShopBot’s

line of PRTalphas

feature advanced, closed-loop

motors and drivers,

giving the

tools a level of

speed and productivity

only seen on

tools five times

more expensive.

ShopBot’s

line of PRTalphas

feature advanced, closed-loop

motors and drivers,

giving the

tools a level of

speed and productivity

only seen on

tools five times

more expensive.

The closed-loop,

“alphaStep” motors and drivers used in PRTalpha combine

the best features of servo and stepper motors - offering

exceptionally fast and smooth cutting motion with no

“tuning” or “hunting” problems. Cutting speeds are two-tofive

times faster than current ShopBots and positioning

speeds are up to 1,800 inches per minute.

ShopBots, manufactured by ShopBot Tools, Inc. of

Durham, N.C., are CNC machines that use basic PC computers

and easy-to-use software, to design, cut and shape

wood, plastic or metal products.

For additional information, contact Diane Reynolds,

ShopBot Tools Inc., 3333 B Industrial Drive, Durham, NC

27704, 800-608-7500 / 919-680-4800, Fax: 919-680-4900, E-mail: info@shopbottools.com, Web: www.

shopbottools.com.

CNC Router Brochure

Thermwood Corp., manufacturer of 3- and 5-axis

CNC routers for trimming and machining of flat sheet and

three dimensional formed

plastics, has published

their new brochure.

Featuring their full-line of

machines, Thermwood

offers several sizes and

configurations each directed

at different applications.

The “Which Router

is Right for You?” section

provides an overview of

the various types of

machines they offer. A

host of options are also

available that can increase

the flexibility and productivity of your CNC router.

Featuring their full-line of

machines, Thermwood

offers several sizes and

configurations each directed

at different applications.

The “Which Router

is Right for You?” section

provides an overview of

the various types of

machines they offer. A

host of options are also

available that can increase

the flexibility and productivity of your CNC router.

For additional information, contact Cliff Crawford,

Thermwood Corporation, P.O. Box 436, Dale, IN 47523,

812-937-4476, Fax: 812-937-2956, E-mail: sales@

thermwood.com, Web: www.thermwood.com.

TOOLING

CNC Toolholders

Integra Tooling

introduced

their new

line of CNC

Toolholders,

collets and

accessories.

The product

line includes

ISO-30, ISO-40 and precision-balanced HSK toolholders

as well as precision collets and other accessories to fit

most CNC routers, machining centers and point-to-point

machines. In addition, high-precision drill toolholders,

saw arbors and multiple-spindle aggregates are available.

The product

line includes

ISO-30, ISO-40 and precision-balanced HSK toolholders

as well as precision collets and other accessories to fit

most CNC routers, machining centers and point-to-point

machines. In addition, high-precision drill toolholders,

saw arbors and multiple-spindle aggregates are available.

For additional information, contact Brian Corbley,

Integra Tooling, 818 Route 25A, Northport, NY 11768,

800-633-6312 / 631-261-4155, E-mail: integratooling@

aol.com, Web: www. integratooling.com.

Engraving-Lettering Tools/New Catalog

For sign makers and graphic designers looking for “V” bottom

engraving and lettering bits, Onsrud Cutter introduced

a significant line of router tools.

The engraving tools are available

in .005 to .090 diameters individually or in kit form. The

lettering line provides superior “V” bottom capability for larger

sign lettering or can be utilized as a chamfering tool.

engraving and lettering bits, Onsrud Cutter introduced

a significant line of router tools.

The engraving tools are available

in .005 to .090 diameters individually or in kit form. The

lettering line provides superior “V” bottom capability for larger

sign lettering or can be utilized as a chamfering tool.

They have also released their 2004

Production Routing Catalog (OC-04) offering

over 2,000 products for the CNC/

Production Routing Industry. The expanded

Production Routing Catalog offers new

and proven products for the wood, plastic,

composite and non-ferrous markets. With

the addition of 200 new products, the catalog

is the most comprehensive source for

poly-crystalline

diamond, monocrystalline

diamond,

diamond

coated, solid carbide,

carbide insert,

high-speed steel and carbide-

tipped milling and routing

tools available today.

For additional information,

contact Marybeth Thomas,

Onsrud Cutter, Inc., 800 Liberty

Drive, Libertyville, IL 60048, 800-234-1560 / 847-

362-1560, Fax: 847-362- 5028, Web: www.onsrud.com

or www.plasticrouting.com.

Plastic Cutting Saw Blades

Pauls Grinding Industries Ltd., manufacturers of

industrial carbide-tipped saw blades,

offers three blades

for cutting

plastics.

The 20A

is a nomelt,

all

corner

bevel style

blade that

provides

smooth cuts. The

20B is designed

for cutting thin material, PVC and extrusions. The

20C, ideal for hard materials and acrylics, features a

“California T.C. Grind” assuring long lasting edges.

offers three blades

for cutting

plastics.

The 20A

is a nomelt,

all

corner

bevel style

blade that

provides

smooth cuts. The

20B is designed

for cutting thin material, PVC and extrusions. The

20C, ideal for hard materials and acrylics, features a

“California T.C. Grind” assuring long lasting edges.

For additional information, contact Kathy Barsony-

Shymko, Pauls Grinding Industries Ltd., 1446 Erin Street,

Winnipeg, Manitoba Canada R3E 2S8, 877-744-7291 /

204-774-2434, Fax: 204-783-9218, E-mail: pgisaw1@

shaw.ca, Web: www.members.shaw.ca/pgisaw1.

Screw-on Tooling

Her-Saf Screw-on Tooling by Safranet Enterprises

Inc. is now being

used in both automated and manual

machines as well as hand held tooling.

used in both automated and manual

machines as well as hand held tooling.

These bits are also known as Quick

Change Cutters because they

reduce downtime when

changing bits: the arbor

stays in the collet while the

dull cutter is screwed off and

a new cutter is spun on in its

place.

The advanced cooling design extends the life

of the carbide and, depending on the material being cut,

improves the cut considerably. The structural design

ensures a balanced tool capable of 22,000 rpms.

For additional information, contact Linda Wyant,

Safranek Enterprises Inc., 4005 El Camino Real,

Atascadero CA 93422, 800-553-9344, E-mail: sales@

hersaf.com, Web: www.hersaf.com.

Plastic Cutting Tools

Southeast Tool, Inc.

now has an expanded 68

page catalog.

They have

become your one stop

source for woodworking

and plastic cutting applications.

They have

become your one stop

source for woodworking

and plastic cutting applications.

With over 3,500 items in

their catalog, they have

added more boring bits,

insert tooling, saw blades,

diamond router bits and

more router bits.

For additional information,

contact Chuck Hicks, Southeast Tool, Inc., P.O. Box

1597, Conover NC 28613, 828-465-7012 Fax: 828-465-

7013, E-mail: router@southeasttool.com, Web: www.

southeasttool.com.

Edge Rounding Tooling

Vortex Tool Company, manufacturers

of high performance

router and insert tooling for woodworking

and the plastics industry,

added the Series 6000 to their

plastics line. These solid carbide

tools were designed for rounding

the edge of plastic sheets and

parts. The double- edge low helix

design provides ultra smooth cuts

while allowing for upward or

downward chip removal. The tools are available as single edge “O” flute and two flute low

helix upcut or downcut in 1/8”, 3/16” and 1/4”.

and the plastics industry,

added the Series 6000 to their

plastics line. These solid carbide

tools were designed for rounding

the edge of plastic sheets and

parts. The double- edge low helix

design provides ultra smooth cuts

while allowing for upward or

downward chip removal. The tools are available as single edge “O” flute and two flute low

helix upcut or downcut in 1/8”, 3/16” and 1/4”.

For additional information, contact Mike Serwa, Vortex Tool

Company, Inc., 5605 Jelinek Avenue, Schofield, WI 54476,

800-355-7708 / 715-355-7707, Fax: 715-355-7353, E-mail:

info@vortextool.com, Web: www.vortextool.com.

MISCELLANEOUS

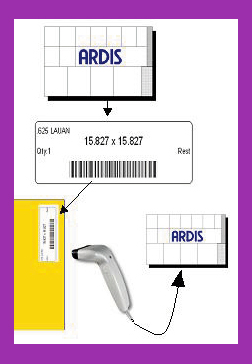

Barcode Feature

EUROSOFT announced the

release of a new ARDIS feature:

The new function works in combination

with a barcode reader

(hardware not included).The

user scans in the barcode

attached to scrap pieces left

over from previous jobs. After

scanning the barcode, the software

searches the database for

the scrap piece that matches

the barcode and then puts it back into the raw material

inventory for the ARDIS Cutting Optimizer. The ARDIS

software will then use these scrap pieces first in the next

optimization run. The combination of barcode scanning

and re-useable scrap detection in ARDIS avoids the common

problem that re-useable drop gets used up or damaged

but the optimization software still has them on

inventory.

The new function works in combination

with a barcode reader

(hardware not included).The

user scans in the barcode

attached to scrap pieces left

over from previous jobs. After

scanning the barcode, the software

searches the database for

the scrap piece that matches

the barcode and then puts it back into the raw material

inventory for the ARDIS Cutting Optimizer. The ARDIS

software will then use these scrap pieces first in the next

optimization run. The combination of barcode scanning

and re-useable scrap detection in ARDIS avoids the common

problem that re-useable drop gets used up or damaged

but the optimization software still has them on

inventory.

For additional information, contact David Talbot,

Eurosoft, Inc. 1628 Old Apex Road, Cary, NC 27513,

919-468-3003, Fax: 919-468-6374, E-mail: david@

eurosoft.com, Web: www.eurosoftinc.com.

Manufacturing Software

Pattern Systems International

(PSI) has created

a new brochure detailing

their suite of manufacturing

software.

The new 4-page, full color

brochure is a fully illustrated,

easy-to-read guide that

describes the various software

programs they offer.

The brochure features a

flow chart style section

describing each product

and includes pictures of what the product does and the

solution it provides.

For additional information, contact Peter Feld, Pattern

Systems International, 200 Valley Road, Suite 302, Mt.

Arlington, NJ 07856, 800-225-7804 / 973-770-3800,

Fax: 973-770-0053, E-mail: peterf@patternsystems.com,

Web: www. patternsystems.com.

Air-Vac-Clamp

With a simple flick of the

foot control, the Her-Saf Air-

Vac-Clamp securely holds

plastics,

metals and nonporous

woods from all lateral

movement. The Air-Vac-

Clamp can easily and quickly

secure a large or small workpiece

while allowing full

access to that workpiece.

The Air-Vac-Clamp secures

and releases the workpiece

without leaving a mark.

metals and nonporous

woods from all lateral

movement. The Air-Vac-

Clamp can easily and quickly

secure a large or small workpiece

while allowing full

access to that workpiece.

The Air-Vac-Clamp secures

and releases the workpiece

without leaving a mark.

Safranek Enterprises,

Inc. products include easy-to-

use panel routers, Air-Vac-Clamps, dentil molding

machine, keyholing machines, carbide insert tooling and a

shelf dapper. Each designed to increase accuracy and precision

while reducing production time.

For additional information, contact Linda Wyant,

Safranek Enterprises Inc., 4005 El Camino Real,

Atascadero CA 93422, 800-553-9344, E-mail: sales@

hersaf.com, Web: www.hersaf.com.

|