|

SAFETY SOLUTIONS: The Aging Workforce

Maintaining the Safety and Health of a Diverse Workforce

As workers born between 1946 and 1964, the

large ‘baby boomer’ generation, age so too does

our workforce while the labor pool shrinks.

Currently, workplace injury rates for older workers are the

lowest of any age group, but their fatality rate is the highest.

To accommodate the aging workforce and to work to

reduce fatality rates, businesses should design a safe

workplace for this aging, but valuable, workforce or be

faced with a negative economic impact.

Businesses must act now to accommodate and provide

a safer work environment for the aging worker, a valuable

and experienced group, or their bottom line will be

impacted negatively. There are easy and economical ways

to do this that, in the long run, will save time, increase

output and contribute positively to the business.

The U.S. Department of Labor’s (DOL) workplace statistics

for 2004 show that those 64 and older had the lowest

number of workplace injuries, but the fatality rate for

those 55 and older rose by 10 percent. In 2003, workers

65 and older continued to record the highest fatality rate

of any other age group, more than three times the rate of

fatalities for those aged 25-34, according to the DOL.

Most of these fatalities were transportation-related, from

falls, from being struck by an object and from homicides.

As baby boomers begin to retire over the next few

years, the DOL notes the workforce will shrink as those

born from 1965 to 1985, a time with a declining

birthrate, enter the workforce. According to American

Demographics magazine, currently there are 76.9 million

baby boomers in the U.S. The majority of boomers live in

California, Florida, Illinois, Michigan, New Jersey, New

York, Ohio, Pennsylvania and Texas.

As the percentage of the workforce aged 55 and over

increases, injury rates for the whole work population decreases

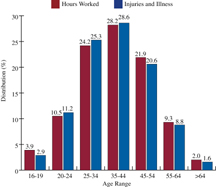

while productivity increases An estimated 3.9 million occupational

injuries and illnesses were treated in hospital emergency

departments among all industry and occupation groups

for workers aged 15 and older. The highest numbers of these

injuries and illnesses occurred among workers aged 25-44.

Existing data suggests there is no age-related safety

performance issue between the 25-54 year age group

and that of the over 55 years age group, according to

2001-02 statistics. Older workers are not more prone to

injury and illness than other workers. Older workers have

fewer avoidable absences, a lower turnover rate, and

fewer work-related accidents.

To increase workplace safety,

employer fixes – environmental

changes – can cost next to nothing,

yet the return on investment is very

high

Management needs to be prepared

to accommodate the number

of changes older workers may face

such as physical, sensory and perhaps

some mental impediments.

As we age we get shorter and heavier,

our muscle strength decreases

and by age 65, the mean maximum

aerobic power – the level at

which oxygen uptake levels off – is

about 70 percent of what it was at

age 25. Hearing and vision is also

diminished as one ages.

Most experts agree that despite

the aging process and its risks,

older workers are not likely to take

it easy on the job. Even though

older workers face additional

obstacles to performing their job,

they bring experience and knowledge

and an excellent work ethic to

the job, making them a valuable

part of the work force. Equipment,

facilities and work processes can

be improved to account for the limitations

of the aging workforce and

to take advantage of their experience

and capabilities.

Knowing that there is no onesize-

fits-all solution, the following

are suggestions that can increase

workplace safety for an aging workforce:

Improve illumination, add color

contrast

Eliminate heavy lifts, elevated

work from ladders and long

reaches

Design work floors and platforms

with smooth and solid decking

while still allowing some cushioning

Reduce static standing time

Remove clutter from control panels

and computer screens and

use large video displays

Reduce noise levels

Install chain actuators for valve

hand wheels, damper levers or

other similar control devices –

this brings the control manipulation

to ground level – helps

reduce falls

Install skid resistant material for

flooring and especially for stair

treads – helps reduce falls

Install shallow-angle stairways in

place of ladders when space permits

and where any daily elevated

access is needed to complete

a task – helps reduce falls

Utilize hands free volume

adjustable telephone equipment

Increase task rotation which will

reduce the strain of repetitive

motion

Lower sound system pitches,

such as on alarm systems, as

they tend to be easier to hear

Lengthen time requirements

between steps in a task

Increase the time allowed for

making decisions

Consider necessary reaction time

when assigning older workers to

tasks

Provide opportunities for practice

and time to develop task

familiarity

Implementing these changes

would not only help older workers,

but would benefit all workers.

Wishing you all a safe and happy

New Year and a prosperous 2006!

For more information, click on the Author Biography link at the top of this page.

|