|

Plastic Piping Systems & Solvent Cementing

Over the last forty years, plastic piping systems have

gone from virtually unknown to some of the most

used systems in both process (pressurized) and

waste (gravity fed) applications. The generic term ”plastic”

encompasses many different materials with so many characteristics

that it would take a book or two to list them all.

However if we confine our inquiry to piping systems, we can

narrow down the field and divide plastics into two families–

thermosets and thermoplastics. Although there are

numerous differences between the two groups, the major

distinguishing factor is that thermosets harden with heat

while thermoplastics are softened by it. Thermoplastics

however are by far the more utilized in both industrial and

plumbing applications, so let’s take a closer look at this

group. PVC, CPVC, ABS, PP, ECTFE …. on and on the

alphabet soup goes. Fortunately it can all be condensed

into three major families plus the odd man out:

- The Vinyl family

- The Polyolefin family

- The Fluoropolymer family

- ABS

Whereas physical, chemical and thermal properties vary

greatly among thermoplastics (covering a broad range of

applications) there are a few, very desirable properties

that they all share:

Light weight – easy to transport, install, support.

High chemical resistance – thermoplastics are far superior

than most metals, including many exotic ones, at a

fraction of the cost.

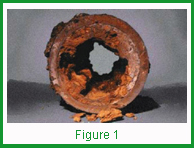

Corrosion resistance –

unlike all metals (including

stainless) which

eventually

oxidize (rust), pit and scale

(Figure 1) or are subject to

galvanic corrosion when

buried, these materials exhibit

no such problems, maintaining a full ID throughout their

entire service life.

eventually

oxidize (rust), pit and scale

(Figure 1) or are subject to

galvanic corrosion when

buried, these materials exhibit

no such problems, maintaining a full ID throughout their

entire service life.

Extremely low roughness factor – only polished metals

can match the smooth surface finish of the most common

thermoplastics. Lower roughness translates to smaller

diameters, less friction losses, smaller pumps, etc. adding

up to substantial savings.

Superior insulation properties – all thermoplastics are

very low heat conductors requiring much less energy or

insulation to maintain the desired temperature of the flow

(chilled or hot). Once again, costs are much lower.

Cleanliness – in installations where it is important that

the piping does not contribute contaminants to the flow,

thermoplastics exhibit what is perhaps one of the most

amazing characteristics; they get cleaner and cleaner over

time. Metals, by contrast, get dirtier and dirtier.

The next thing to consider is the ease of assembly of

thermoplastics vs. metals. Mechanical joints (e.g. flanges,

threads, etc.) are equally available for both types of materials

but lining up two 20 foot pieces of 4” carbon steel so

they can be flanged together is quite a bit more difficult

than attempting the same thing with substantially lighter

pieces of plastic pipe. Also, all mechanical connections

have the tendency to leak over time and/or require constant

maintenance. These are some of the reasons why

permanent joints are much more desirable in most industrial

and plumbing applications.

But as we turn our attention to permanent jointing

things change dramatically. There are no longer only differences

between thermoplastic and metals but among

the 4 different thermoplastics as well (Vinyls, Polyolefins,

Fluoropolymers, and ABS).

The only way to permanently join all metals, Polyolefins

and Fluoropolymers is through some kind of welding process. Whether the components are directly welded to

each other or an addition of melted material is needed,

these processes are complex, require (often expensive)

equipment used by highly trained installers, and can be

cumbersome and difficult to perform in tight spaces.

Only piping systems manufactured using either Vinyls

(PVC and CPVC) or ABS materials lend themselves to a

very unique and effective permanent jointing process

which has none of the above listed limitations – Solvent

Cementing.

I can already ‘hear’ many readers say “Oh sure, glued

systems”; well, not quite.

Solvent cements were developed in the 1950’s by IPS®

Corporation under the Weld-On® brand name, creating a

simple solution to the problems contractors faced in joining

pipe.

Besides the very substantial formulation differences

between glues (adhesives) and cements, there is an

extremely fundamental difference with regard to “how

they work.” Glue bonds the two parts—think of it as two

flat pieces of any material with a piece of chewing gum inbetween.

Without the gum the two pieces wouldn’t stick.

This means that a glued joint needs the glue to remain as

the bonding agent and, to be leak-proof, the glue must be

evenly distributed over the entire surface to be sealed.

A solvent cement joint, by contrast, is a chemical fusion

that occurs between two identical materials. In our solvent

cement joint we actually require substrate to substrate

(e.g. OD of the pipe and ID of the fitting) contact because

the chemicals in the solvent cement are not the “glue” that

holds the pieces together but rather they are what allow

the materials to fuse together. As long as the surfaces of

the two components to be joined are properly prepped and

coated with the right amount of cement (to fill any gaps),

they will fuse where there is direct contact between the

parts and bond where there are gaps. For this reason, fitting

sockets are tapered and the most important part of a

solvent cement joint is the bottom 1/3 of the fitting socket;

that’s the area where there is interference (contact)

between the pipe and the fitting and thus that is the fusion

area. A properly constructed and cured solvent cement

joint will exhibit a greater resistance to pressure than the

individual components that make up that connection.

From an installation stand point, the tremendous

advantage of solvent cementing is that no bulky/expensive

equipment is required to obtain high integrity/permanent

connections and that training of inexperienced personnel

is very straight forward and can be performed in a few

short hours.

Let’s take a very generic look at the process and what it

entails.

There are three basic products that are used in solvent

cementing:

- Cleaner

- Primer

- Cement

- The use of cleaners is not always a must. However if

dirt, grease, oil or surface impurities are present on the

areas to be jointed, a cleaner must be used. Two things

are very important to note: (a) Cleaners are not interchangeable

with Primers and (b) when used, Cleaners

must be allowed to evaporate completely before moving

on to the next phase.

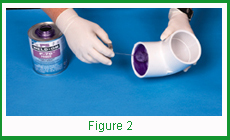

- Primers are often the least understood part of this

process and yet they are as important as the cement

itself. Correct use of primers is essential to prepare (soften)

the surfaces of the pipe and fitting so that the fusion

process can occur. To work properly primers must be vigorously

scrubbed into the surface; we are not painting, we

are priming! (Figure 2) Two applications of primer are necessary

for the valve or fitting vs. one for the pipe. This is

due to the different manufacturing processes between the

two components—extrusion for the pipe and injection

molding for the valve or fitting. Unlike the step before, the

step from primer to cement must be performed when the

primer is still wet.

process and yet they are as important as the cement

itself. Correct use of primers is essential to prepare (soften)

the surfaces of the pipe and fitting so that the fusion

process can occur. To work properly primers must be vigorously

scrubbed into the surface; we are not painting, we

are priming! (Figure 2) Two applications of primer are necessary

for the valve or fitting vs. one for the pipe. This is

due to the different manufacturing processes between the

two components—extrusion for the pipe and injection

molding for the valve or fitting. Unlike the step before, the

step from primer to cement must be performed when the

primer is still wet.

One-step cements (no primer required) are available for

less demanding applications, but we’ll have to leave that

discussion for some other time.

- The final phase is the application of cement. For the

most part, cements must be material specific (PVC, CPVC

or ABS) and must be selected based on the application

(pressure, non pressure, chemicals, sizes, temperatures,

etc.). Once the right cement is chosen and with our pipe

and valve/fitting still wet with primer, we apply the cement

to the surfaces to be joined. This time we go over the pipe

twice and only once inside the socket. This is done

because we do not want too much cement inside the socket

which would puddle inside the socket thus damaging

the valve or restricting the joint ID.

By contrast, be generous with the cement application

on the pipe, as the excess cement will be dragged out of

the joint and give you a nice seal around the mouth of the

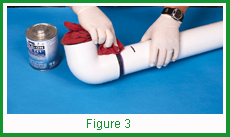

socket, plus it is easy to wipe off. It is now time to insert

the pipe into the socket, twisting the pipe ⁄ turn as it is

inserted (twisting is not necessary if using a pipe-puller).

Stop twisting as you bottom out, and then hold the pipe

down for a few seconds to prevent the fitting taper from

kicking it out. Your joint is now done! (Figure 3) Note that

cure time before handling and pressure testing will vary

greatly based on sizes and working temperature.

the joint and give you a nice seal around the mouth of the

socket, plus it is easy to wipe off. It is now time to insert

the pipe into the socket, twisting the pipe ⁄ turn as it is

inserted (twisting is not necessary if using a pipe-puller).

Stop twisting as you bottom out, and then hold the pipe

down for a few seconds to prevent the fitting taper from

kicking it out. Your joint is now done! (Figure 3) Note that

cure time before handling and pressure testing will vary

greatly based on sizes and working temperature.

The above description is not meant to be a “how to”

instruction which would include additional important

steps. However, solvent cementing is relatively

simple/inexpensive and the reason why Vinyl and ABS systems

are often preferred. But such simplicity sometimes

leads to the erroneous perception of it being a ‘less effective’

method. That’s incorrect; although proper cementing

does require training and the strict observance/implementation

of specific steps, cementing remains a simple

process which produces exceptionally tough, permanent

joints with remarkable yield and a life expectancy well

beyond what the individual components can offer.

Written by Fabio Castellani, VP Sales - IPS® Corporation.

IPS® Corporation is the inventor of the plastic pipe solvent

cementing process and the manufacturer of the Weld-On®

brand solvent cements for use on piping systems (PVC,

CPVC, and ABS) in various applications, including irrigation,

industrial chemical transport systems, pool and spa

and residential/commercial water distribution systems.

For more information, contact Fabio Castellani, IPS

Corporation, 455 W. Victoria Street, Compton, CA 90220,

800-421-2677, Fax: 310-898-3390, E-mail: fabio.castellani

@ipscorp.com, Web: www.ipscorp.com.

|