|

Colasit Constructs Three Bio-washer Silos

In an otherwise empty

industrial building, previously

used by the Swiss

army, big things are emerging:

The company Colasit

from the Berner Oberland

region of Switzerland rented

the building on a temporary

basis to prefabricate 25 mm

thick polyethylene panels

that would subsequently be

assembled in Spain. Three

massive silos were built in

the Basque Country, as commissioned

by the German

company m+w Zander

Gebäudetechnik GmbH;

these are now used in the

biological washing process.

They were integrated into a cellulose production plant.

Using this technique, organic airborne pollutants are now

extracted biologically in a multi-stage process. The waste

gases flow through packed beds, are absorbed on the surface

of substrate substances and are decomposed by

micro-organisms. The bio-washer results in a considerable

reduction in odor and pollutant emissions. The population

of Torrelavega and the surrounding region therefore waited

eagerly for the plant to

be commissioned.

from the Berner Oberland

region of Switzerland rented

the building on a temporary

basis to prefabricate 25 mm

thick polyethylene panels

that would subsequently be

assembled in Spain. Three

massive silos were built in

the Basque Country, as commissioned

by the German

company m+w Zander

Gebäudetechnik GmbH;

these are now used in the

biological washing process.

They were integrated into a cellulose production plant.

Using this technique, organic airborne pollutants are now

extracted biologically in a multi-stage process. The waste

gases flow through packed beds, are absorbed on the surface

of substrate substances and are decomposed by

micro-organisms. The bio-washer results in a considerable

reduction in odor and pollutant emissions. The population

of Torrelavega and the surrounding region therefore waited

eagerly for the plant to

be commissioned.

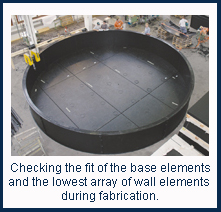

Each silo consists of four

stacked arrays, each with

ten wall elements. The panels

of the three upper arrays

are 3.8 m high, 2.67 m

wide and weigh 300 kg,

those in the lowest array are

half the dimensions. In

Thun, Switzerland, they

were first mounted on a fixture

device with a 4.25 m

radius. In order to maintain

the curvature, arch struts

slot-milled on both sides

were mounted of the upper

edge of the panels and

extrusion joined on the

inside and outside. The 210° to 230° hot extruded material

was delivered by powerful Weldplast EC4 and S4 hand

extruders from Leister (EC4 with brushless motors for

worm drive and hot air).

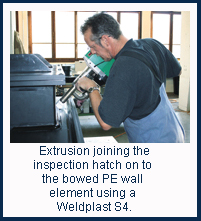

Three inspection hatches and a manhole were

also welded

on the curved PE panels. The Leister hand extruders

also proved themselves equal to this awkward task. To

ensure that the hatches did not deform while the extrusion

material cooled, the covers were screwed on temporarily

after welding. As a fixture aid for the insulation to

be mounted later in Spain, four horizontal struts were also

mounted on the outside of the individual elements. Here

a simple welding seam was sufficient. The 4 mm thick welding

seam was produced with the DIODE S hand tool from Leister.

also welded

on the curved PE panels. The Leister hand extruders

also proved themselves equal to this awkward task. To

ensure that the hatches did not deform while the extrusion

material cooled, the covers were screwed on temporarily

after welding. As a fixture aid for the insulation to

be mounted later in Spain, four horizontal struts were also

mounted on the outside of the individual elements. Here

a simple welding seam was sufficient. The 4 mm thick welding

seam was produced with the DIODE S hand tool from Leister.

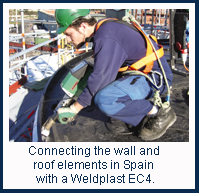

Leister tools were also used in the final assembly phase in

the Basque Country: Around 10 Colasit employees welded

around the clock, 6 days a week using the Weldplast S4 and

EC4 (brushless) extruders. With an output rate of up to 4

kg/h, joining of the parts proceeded apace. The individual

panels were mounted in a ring structure and were screwed

together on the

sides. The vertical

joints were then

welded. Once the

first array was finished,

the panels

for the second

array were inserted

into the slot of

the lower array

offset to the side

and were extrusion

joined on the

inside and outside

of the panels. The base and roof segments made of PE

were also welded to the wall elements in Spain.

around the clock, 6 days a week using the Weldplast S4 and

EC4 (brushless) extruders. With an output rate of up to 4

kg/h, joining of the parts proceeded apace. The individual

panels were mounted in a ring structure and were screwed

together on the

sides. The vertical

joints were then

welded. Once the

first array was finished,

the panels

for the second

array were inserted

into the slot of

the lower array

offset to the side

and were extrusion

joined on the

inside and outside

of the panels. The base and roof segments made of PE

were also welded to the wall elements in Spain.

The three completed silos boast impressive dimensions:

wall height 13.5 m, diameter 8.5 m, circumference 26.7 m.

The plastics specialist from Colasit processed 45 tons of PE

panels in total. The total welding seam length amounted to

around 5 km!

The plastics specialist from Colasit processed 45 tons of PE

panels in total. The total welding seam length amounted to

around 5 km!

When the production plant in Spain goes into operation,

each of the three silos filled with 510 m3 wash packing and

water weighs around 200 tons. No question that the strength

of the joints is subject to extraordinary demands.

For Colasit, this contract was one of the biggest in its company’s

over 60 year history. Besides the logistics challenge, the

tight schedule also had to be observed: In just 5 1/2 months,

all the prefabricated elements had to be ready, transported to

Spain on nine trucks, the three silos built up and the complete

system connected with the cellulose production plant.

For more information, contact LEISTER Process

Technologies, Riedstrasse, CH-6060 Sarnen/Switzerland, 41

41 662 74 74, Fax: 41 41 662 74 16, E-mail: sales@leister.com, Web: www.leister.com.

|