|

IWF Fair/SPE Preview

The International Woodworking Machinery & Furniture

Supply Fair-USA® will feature nearly 1,500 exhibitors

August 20-23, 2008 at the Atlanta Convention Center,

Atlanta, Georgia. At IWF 2008 there will be the opportunity

to view technology that will decrease production

costs, while improving profits, creating new opportunities

for economic growth while sustaining a global competitive

edge in the global marketplace.

The following companies will be showing machinery and

tooling designed specifically for the plastics industry.

For

more information on IWF 2008, visit www.iwfatlanta.com.

The 18th Annual SPE Thermoforming Conference and

Exhibition will host over 1,000 attendees and nearly 100

exhibitors at the Minneapolis Convention Center in

Minneapolis, Minnesota, September 20-23, 2008. This

show will be a forum for the newest techniques, latest

equipment, materials, auxiliary equipment and current

industry news. The conference will also feature multiple

technical sessions targeting roll-fed and cut-sheet thermoformers.

The following companies will be exhibiting

products for cut-sheet thermoformers.

For information

and registration visit www.thermoformingdivision.com.

Diamond Edge Polishers

AD Beyond Machinery

Company will debut

their Model FF (Five

Footer) Diamond Edge

Polisher with a polishing

capacity of 62”

long and up to 4” thick

in the A.W.E.D. Booth

at IWF 2008. The polisher

is equipped with

a 1 1/2 hp direct drive, single phase

220v spindle motor that provides fast

polishing speeds and a high quality finish.

AD Beyond is also offering a table top diamond

edge polisher that is capable of polishing a 45°

bevel, without pre-cutting, up to 7/32”. The polisher is

ideal for beveling small parts, especially on four sides.

For additional information, contact Victor Miranda,

A.W.E.D. Corp., 1175 Buford Hwy., Suite 101, Suwanee,

GA 30024, 770-831-9800, Fax: 770-831-7404, E-mail:

victor@awedmachine.com, Web: www.awed-machine.com.

IWF 2008 Booth #8170

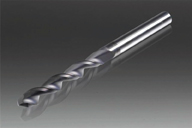

Solid Carbide Spiral

Plastic O-Flute

Amana Tool’s new solid

carbide spiral plastic O flute

router bits are

designed to produce

super clean, smooth

cuts in acrylic materials

such as Plexiglas®,

Lucite® and other plastic materials. The bits are made of

an exclusive carbide grade and finished to a mirror finish

with Amana’s unique polishing process. The bits are available

in a 1/4” diameter with a right-hand Helix cut, which

is designed to throw the chips upward, and a left-hand

Helix cut designed to throw the chips downward. These

two popular designs work well with most CNC vacuum systems

and are designed to cut acrylic, nylon, ABS, PE,

acetal, PET, HDPE, UHMW, polycarbonates, polypropylene,

wood and solid surface.

Amana offers same-day shipping across North America.

Products can be received in as little as one day from fully

stocked East and West Coast fulfillment centers.

For additional information, contact Michele Spiegel,

Amana Tool, 120 Carolyn Blvd., Farmingdale, NY 11735,

800-445-0077, Fax: 631-752-1674, E-mail: sales@

amanatool.com, Web: www.amanatool.com.

IWF 2008 Booth #6069

3-Axis Router Tables

AXYZ Automation manufactures a full line of computer

3-axis router tables used for routing, drilling, dispensing,

stud welding and plasma cutting which interface

with all desktop design systems.

One of the newest members of

the AXYZ Series family is the

5000. With a processing

width of 70 inches, it allows

customers to work with oversized

sheet goods without pre-trimming

material.

For additional information, contact Christina D’Angelo,

AXYZ Automation, Inc., 5330 S. Service Rd., Burlington,

ON L7L 5L1 Canada, 800-361-3408/905-634-4940,

Fax: 905-634-4966, E-mail: blowe@axyz.com, Web: www.axyz.com.

IWF 2008 Booth #6535

CNC Routers and Lasers

CDM Industries, with over 20 years experience in the

computer-driven machinery business, represents

China’s premier manufacturer of CNC routers and lasers,

VICCAM Technology Enterprise Co., Ltd.

With thousands of successful,

worldwide installations, VICCAM

has built a reputation for reliability,

accuracy and value for ondemand-

manufacturing. CDMVICCAM

offers a range of standard

and custom-made CNC

routers and lasers for many applications

and materials including wood, plastic, metal,

stone, composite, solid surface, foam, rubber and paper.

The equipment incorporates the highest quality manufacturing

techniques and industry

standard component

parts, user-friendly controls

and software.

Table sizes are from 12” x

24” to 78” x 165” with spindles

from 1 hp to 16 hp and

lasers from 60 watts to 3000 watts. Their

packages include special financing, dust collection, computer

and software, tooling, vacuum pump, laser chillers

and spare parts kits. Backed with a two-year limited warranty,

trade up program and web-based support.

Immediate delivery from IWF2008.

For additional information, contact Cahir McCoole,

CDM Industries, P.O. Box 883, Marblehead, MA 01945,

781-608-4400, E-mail: cdmindustries@aol.com, Web:

www.cdm-industries.com.

IWF Booth #6352

CNC Machining Centers

CMS North America, a division of CMS Industries of

Zogno (BG) Italy,

is a designer/manufacturer

of CNC machining

centers for

working wood, plastics,

composites, aluminum,

stone, glass

and solid surface

material. CMS offers

ideal machine solutions for applications in aerospace,

automotive, marine, molds, doors, staircases and more.

CMS introduces the new ATHENA 10-5 TUCU 5-axismachining center, equipped with a 10’ x 5’ working area; a

9 hp, 24,000 rpm, 5-axis air-cooled spindle with HSK 63F

connection and a 6-place tool changing rack. The working

table is connected to the base frame and has machined surfaces

supplied with threaded holes for attaching fixtures. It

also features enclosed sides and back with front manual

sliding doors for operator safety and noise reduction. The

ATHENA offers a compact size at 20’ x 8’ x 11’ H; OSAI type

10/510 S Series Numerical Control with Auto-Teaching

System and PowerARM software. The dry vacuum plant

offers a high level of vacuum for good piece clamping.

For additional information, contact CMS North America

Inc., 4095 Karona Court, Caledonia, MI 49316, 800-225-

5267/616-698-9970, Fax: 616-698-9730, E-mail:

cmssales@cmsna.com, Web: www.cmsna.com.

IWF 2008

Booth #8226

SPE Booth #430

Fast Cross Cutting Speeds

Delmac

Machinery Group shows that at 12 cross cuts per minute, Mayer’s high speed control

gives users the fastest cross cutting speeds in the

industry while maintaining excellent cut quality.

With over 30 years experience, Mayer has developed

design philosophies and principles aimed at producing

machines with superior cut quality, accuracy, speed and

flexibility for the wood and plastics industries. The PS2

Z120 offers a high output

with its 4.7” blade

projection (optional

7.8” cutting

height) and fast

traverse speeds

while maintaining the

dimensional accuracy and

superior cut quality required by the most discriminating

customers.

For additional information, contact Gerri Bolton, Delmac

Machinery Group, 4322 Piedmont Pkwy., Greensboro, NC

27410, 336-854-1211, Fax: 336-854-0811, E-mail:

gbolton@delmac.com, Web: www.delmac.com.

IWF 2008 Booth #8922

3- and 5-Axis Routers

Diversified Machine Systems will be exhibiting three

different machine designs at IWF 2008 and the SPE

Thermoforming Conference including a brand new product

to be revealed exclusively at SPE in September. At IWF 2008, DMS

will be running two

machines, their popular

cost-effective D3 3-

axis CNC Router and

the Enclosed D5 5-axis

router.

However there will

be even greater interest

and excitement

when DMS unveils its latest entry into the market - a high

speed universal platform machining cell. The SSG as it is

known has been designed in response to customer

demands for extra workspace flexibility and better access.

The SSG is faster than conventional machines with high

speed rapids and rotaries. Its large work area can also be

split to run in twin table mode. See the machine in action

for the first time at SPE 2008 in September.

For additional information, contact Ed Hilligrass, DMS

CNC Routers, 2310 Executive Circle, Colorado Springs CO

80906, 719-226-5066, Fax: 719–226-9810, E-mail:

info@dmscncrouters.com, Web: www.dmscncrouters.com.

IWF 2008 Booth #9770

SPE Booth #246

Optimization/Scrap

Management

ARDIS Optimization from

Eurosoft is an easy way to

reduce your shop’s environmental

impact. The optimizer reduces

scrap by calculating the best possible

cutting pattern based on

your cut lists and raw material

sizes. A number of features can

be added to the optimizer to further increase yield, re-use

scrap, manage inventory and improve workflow. Adding

features is easy, and can be done at any time. ARDIS integrates

seamlessly with all design software and makes of

beam saw.

Optimizers sometimes use small parts as fillers to

increase the yield on patterns with large, bulky parts. The

problem is that these parts are not always arranged to

take the saw efficiency into account. The newest Ardis

plug-in provides unprecedented control over the output of

these small parts. You can now specify how small parts

should be arranged on a per part basis. As a result, you’ll

get patterns which are easier to cut, without a large sacrifice

in yield.

For additional information, contact David E. Talbot,

Eurosoft, Inc., 1628 Old Apex Road, Cary, NC 27513,

919-468-3003, Fax: 919-468-6374, E-mail: david@eurosoftinc.com, Web: www.eurosoftinc.com.

IWF 2008 Booth #5046

Inserts for Plastics

E-Z LOK has introduced a new line of ultrasonic thread

inserts designed to provide strong threads in thermoplastic.

The brass inserts are

engineered for use in

tapered holes and are

available in single and

double vane designs.

Internal thread sizes range from 2-56 to 3/8-16 and 10-32

to 3/8-24. E-Z LOK ultrasonic inserts can be installed with

either ultrasonic insertion equipment or a heat driver. The

tapered design reduces installation time and improves

torque and pull out resistance. In addition, the tapered

design applies minimal stress to molded hole walls.

Ideal for plastic components requiring assembly and

disassembly, ultrasonic inserts are typically used in computer/

instrument cases, terminal boards, electronics and

communications equipment.

For additional information, contact Steve Schaeper, E-Z

LOK, 240 E. Rosecrans Avenue, Gardena, CA 90248,

800-234-5613/310-323-5613, Fax: 310-353-4444,

E-mail: ezlok@ezlok.com, Web: www.ezlok.com.

IWF

2008 Booth #4220

3-Axis CNC Routers

The new SR Series Sheet Routers from Haas

Automation, Inc. are affordable solutions that provide

expansive capacity in lighter-weight, gantry-style, 3-axis

CNC machines. The SR-100, with 100” x 52” x 8” (xyz)

travels, easily accommodates 4’ x 8’ sheets of material.

The larger SR-200, with

148” x 76” x 8” (xyz)

travels, handles sheets up

to 6’ x 12’. Both machines

accept ISO standard G-code

programming through the userfriendly,

full-function Haas CNC

control.

Each SR Series router comes

equipped with a 24,000 rpm, 5 hp (continuous), 30-taper

spindle for cutting and drilling various plastics, sheet metals

and other light materials. The open-frame design of

the SR Series machines allows users to design their own

table and fixturing specifically to meet their individual

needs.

The overhead gantry assembly travels the full length of

the fixed table on precision, low-friction linear guides,

resulting in extremely accurate positioning. Powerful,

brushless servomotors on all axes produce high-speed

rapids for fast cycle times. The standard configuration

includes a 15” color LCD monitor and USB port.

For additional information, contact Scott Rathburn,

Haas Automation, Inc., 2800 Sturgis Road, Oxnard, CA

93030, 805-988-6922, Fax: 805-968-6918, E-mail:

srathburn@haascnc.com, Web: www.haascnc.com.

IWF

2008 Booth #6712

Industrial Class Panel Saw

Hendrick will display their SRP Enhanced Industrial

Class Series high-speed computerized panel saw

designed for plastic cutting applications at IWF 2008. The

machine is equipped with a variable

speed 24 hp main blade

motor and 3 hp scoring

motor. Standard with the

SRP is a solid pusher with

material grippers, material

indexing speeds up to

3,000 inches per minute, with a

Windows™ XP® Professional PC Controller, LAN interface

and onboard optimization software. The SRP 3200 PL also

features solid back tables, spray mist coolant on main

blade and automatic blade height adjustment.

For additional information, contact Jeff Grant, Hendrick

Mfg. Corp., 32 Commercial Street, Salem, MA 01970,

978-741-3600, Fax: 978-744-0242, E-mail: jgrant@hendrickmanufacturing.

com, Web: www.hendrickmanufacturing.com.

IWF 2008 Booth #8753

Polymer Sheets, Slabs

and Massive Shapes

Now celebrating its 40th anniversary, King Plastic

Corporation, is a leading

innovator and manufacturer

of high-quality polymer

sheets, slabs and massive

shapes. While the

company is well known for

its King StarBoard® family

of marine polymers, there

is much more to King. Its

polymer products include

an extensive list of commodity polymers: UHMW/VHMW,

HDPE/LDPE, cutting board, borated PE, pipe grade and

polypropylene, as well as colorful signage/playground PE,

sturdy restroom partition sheets and engineering materials

such as ABS.

King Plastic Corporation manufactures 29 products in

sheets, slabs and massive shapes to industry-leading standards

and tolerances, sheets to more than 120’ x 8’, slabs

to more than 30” thick and massive shapes to more than

5,000 pounds.

For additional information, contact King Plastic

Corporation, 1100 N. Toledo Blade Blvd., North Port, FL

34288, 941-493-5502, Fax: 941-497-3274, E-mail: support@kingplastic.com, Web: www.kingplastic.com.

IWF

2008 Booth #4357

Robotic Trimming and

Offline Programming

KMT Robotic Solutions Inc. will showcase its popular

RoboTrim® RT-1002 router trimming system and revolutionary

CAMpro® offline programming software at the

2008 SPE Thermoforming Conference. The RoboTrim ®

RT-1002, KMT’s most popular standard routing system, is

a cost-effective solution that helps thermoformers, plastics

molders and composite manufacturers increase

throughput, uptime and employee safety.

The RoboTrim RT-1002 system trims parts more than

50 percent faster than traditional five axis CNC’s and

offers trimming flexibility. The ergonomic design improves

employee safety by distancing operators from the potentially

harmful trimming environment.

The standard model features a KMT AccuTrim® R-44

robot mounted inside a steel enclosure. The system’s twosided

rotating table has a 1,000 pound part and fixture

capacity and can rotate parts into and out of the cell in

less than three seconds. This allows finished parts to be

safely unloaded by

the operator while

unfinished parts are

being trimmed inside

the cell.

For additional information,

contact

Suzanne Carter, KMT

Robotic Solutions,

Inc., 1255 Harmon Road, Auburn Hills, MI 48326, 248-829-2800, Fax: 248-829-2750, E-mail: suzanne.carter@kmtgroup.com, Web: www.kmtgroup.com/robotic.

SPE 2008 Booth #540

Heavy-duty Cutting

System

MultiCam offers an innovative, heavy-duty, precision

cutting system for plastic and acrylic fabricators.

Their 3000 Series CNC Router is loaded with standard features and is specially suited for machining plastic. The

rigid, all-steel, plate frame construction combined with an

automatic tool changer and 5.5 hp, 32,000 rpm spindle

all allow for an incredible

edge finish when

machining plastic. The

3000 series router

also comes in a wide

variety of sizes and

features a space-saving,

moving-gantry

design. In addition,

MultiCam has vacuum fixturing options specifically tailored

to the plastics industry.

For additional information, contact MultiCam LP, 1025

West Royal Lane, DFW Airport, TX 75261, 972-929-4070, Fax: 972-929-4071, E-mail: sales@multicam.com,

Web: www.multicam.com.

IWF 2008 Booth #6035

Tooling for Plastics

In the world of CNC routing,

proper usage of tooling

is the key to productivity

and profitability. If your

company is looking for the

edge to increase bottom

line profits, the Onsrud

advantage may be for you.

During IWF 2008, Onsrud Cutter LP and their team of

application specialists will be demonstrating the advantage

of proper tool selection and application by running

live parts in the booth with a state-of-the-art CNC router.

The materials will include wood, plastic and aluminum,

which represent real world applications encountered by

the typical CNC shop everyday.

Drill Clean Holes in Composites

A diamond coated parabolic drill has been developed by

Onsrud Cutter that is suitable for drilling both carbon fiber

and graphite epoxy materials. The new drill overcomes typical

problems such as delaminating, flaking and splintering

encountered while drilling composite materials. The drill is

also a lower cost alternative to PCD tipped drills.

The Parabolic Flute design is able to evacuate a large

volume of chips while the multi-layer nano-crystalline, six

micron thick coating is resistant to wear and abrasion. The

special split point reduces thrust, improves centering and

the secondary point angles create a self-seating, reaming

action that directs chips away from the inner hole wall.

Onsrud Cutter is the only cutting tool facility in the

United States that manufactures high-speed steel, carbide

tipped, solid carbide, diamond coated and PCD CNC

router tooling. Onsrud manufactured their first router bit

in 1920.

For additional information, contact Diane Sullivan,

Onsrud Cutter LP, 800 Liberty Drive, Libertyville, IL

60048, 847-362-1560, Fax: 847-362-5028, E-mail:

dsullivan@onsrud.com, Web: www.onsrud.com.

IWF

2008 Booth #8126

SPE Booth #131

High Precision Machining

Products

C.R. Onsrud, Inc. offers a comprehensive line of high

precision machining products including 33 standard

models of 3-, 4-, and 5-axis CNC Routers, four models of

Inverted Pin Routers, as well as a complete line of tooling

and accessories. CNC Routers are offered in Cast-Iron

Fixed Bridge, Twin Table, Single Table and Steel Frame

Moving Gantry designs. Most C.R. Onsrud CNC Routers

include 12-position tool changers,

high grade “off-the-

shelf” standard

components, 24/7

tech-support and all

can be customized

via a full menu of

standard options including: multi-spindle drills, aggregate

stations, rotational C-axis, 5-axis and multi-spindle configurations.

C.R. Onsrud has invested in superior service capabilities,

high-tech training facilities and an extensive

Applications Engineering department to further reinforce

their pledge to provide the industry with the best products,

service and customer support.

For additional information, contact C.R. Onsrud Inc.,

P.O. Box 419, Troutman, NC 28166, 800-638-8185/704-528-4528, Fax: 704-528-6170, E-mail: sales@cronsrud.com, Web: www.cronsrud.com.

IWF 2008 Booth

#8206

New Panel Saw

Schelling’s newest precision panel saw, the fk4 will be

showcased at this year’s IWF show in Atlanta. This is the latest addition to their new fk high speed series that

cuts all types of plastics. This new series blends all of

Schelling’s traditional strengths with their new revolutionary

high speed and PLUS+

features. The design of the fk

machines centers around the

new Evolution saw carriage

and is enhanced through new

PLUS+ features such as

speed, power and precision making Schelling the innovation

leader in drive technology.

The new fk4 has a revolutionary design that offers the operator

the highest cutting capacity for plastics on the market.

For additional information, contact Stephen Bailey,

Schelling America, Inc. P.O. Box 80367 Raleigh, NC

27623, 919-544-0430, Fax: 919-544-0920, E-mail:

sbailey@schelling.com, Web: www.schelling.com.

IWF

2008 Booth #9326

Panel Saws for Cutting

Plastics

SCM Group will feature several panel saws and CNC

routers designed specifically for plastic distributors

and fabricators at IWF 2008. Galaxy and Sigma PLM

panel saws provide superior cutting quality while reducing

material waste and improving productivity at an affordable

price. The new Galaxy T3 (4.5” cutting

capacity) and Sigma

SZ 105 Plast (3.75”

cutting capacity) will be

available for demonstration

in Booth 8740

and Booth 8840.

Value added features include

high speed carriage movement with optimized

operation for fastest cycle times; a worktable designed to

cut thin materials; rpm control on independent main

motor for best edge results; main blade cooling; 48” wide

rear phenolic crosscut table for effectively cutting thin

strips and small parts and a pusher with clamps for quick,

accurate loading and cutting. All saws include powerful

easy to use software that simplifies and speeds the cutting

process.

Additional features include on line self diagnostics and

capability for remote machine access by SCM’s technical

department. Saws are available in 10.5’, 12.5’ or 14.5’

cutting lengths.

CNC Routers for Plastics

SCM GROUP introduces the Morbidelli Universal and

Routech Accord CNC Router Lines for machining all types

of plastic materials. These models bring affordable CNC

machining capability with a “bridge style design” to plastic

distributors and fabricators. Both

models feature a 4’ x 12’ or 5’ x 12’

work area, powerful 12 hp HSK F63

router motor and a variety of automatic

tool changer options.

The flexible aluminum

grid vacuum table provides

effective hold down

for small parts. The userfriendly

software and operator interface

can be used with all major design software

packages.

See the Universal in

Booth #8826 and the

Accord in Booth #8852.

SCM Group also introduces

the Routech R210

Prisma 5-Axis Router (Booth #8862),

a highly flexible router that offers plastic fabricators a high

degree of manufacturing flexibility in both 3- and 5-axis

applications. Perfect for fabricating close tolerance precision

plastic parts, the router comes standard with a powerful

15 hp liquid chilled electro spindle (variable speeds from

900 to 20,000 rpm) and a variety of tool changer options.

For additional information, contact Phil Bryant, SCM

Group USA Inc., 2475 Satellite Blvd., Duluth, GA 30096,

770-759-3534, Fax: 770-813-8819, E-mail: pbryantscmgroup-usa.com, Web: www.scmplastics.com.

IWF Booth

#’s 8740, 8840, 8826, 8852

Small-footprint CNC

ShopBot “Buddy” with Power Stick is a 2008

Challengers Award Finalist. A powerful but small-footprint

CNC, it is easily moved or expanded to add flexibility

to production and manufacturing. The highly mobile

Buddy is fitted with a standard table of either 24” x 32”

or 24” x 48”, weighs less than 600 pounds, and occupies

less than 16

square feet of floor

space. The innovative

PowerStick can

replace a standard

table to provide

expanded work

areas over 8’ long

for large cutting,

drilling or machining

projects or to

allow multiple sets of fixtures for production efficiency.

The ShopBot PRSalpha systems feature technologically

advanced, closed-loop motors that combine the best features

of servos and steppers. With rapid transit speeds of

up to 1,800 inches per minute, and cutting speeds up to

600 inches per minute.

For additional information, contact Martha Barbour,

ShopBot Tools, Inc., 3333-B Industrial Drive, Durham, NC

27704, 888-680-4466/919-680-4800, Fax: 919-680-4900, E-mail: martha@shopbottools.com, Web: www.shopbottools.com.

IWF 2008 Booth #8649

Optimize

Material,

Equipment and

Work Flow

Stiles Machinery Inc. is proud to

showcase their solutions to help

plastic fabricators deliver greater

productivity and lower costs across

the entire operation.

Cut Rite software saves yield, time

and money by creating easy to cut

patterns based on your parts

requirements and downloading

them directly

in the

control

on the

saw,

eliminating

all set-up time and the potential

for set-up error on the shop floor. As a side benefit, Cut Rite produces

a cost per part and a cost

per order: great tools for

quoting new business

accurately. Just to ensure

that the right part gets to

the right job Cut Rite will produce

a bar-coded label at the saw while the part is cut.

Designed exclusively for sizing plastic and component

panels, the Holzma HPP 380P panel saw features a variable

speed main saw motor and automatically selects the

ideal blade rim speed and cutting speed for each material.

The saw carriage is equipped with the unique Holzma

side pressure device which adjusts the pressure according

to material type and achieves beautiful edge quality, even

with thin PETG.

The Weeke Vantage 33P is the fastest and heaviest

machining center in its class, which will result in higher

throughput, tighter tolerance and greater repeatability in

parts production. This gantry-style machine is designed to

handle individual part programs or full sheets for nesting

applications. The patented automatic spindle clamping

system guarantees precise machining every time, regardless

of material type.

A national technical support network and same day

spare parts program ensure that no matter where you

are located, you can get technical assistance when you

need it.

For additional information, contact Bill Pitt, Stiles

Machinery Inc., 3965 44th Street SE, Grand Rapids, MI

49512, 704-861-8239, Fax: 616-698-7521, E-mail:

bpitt@stilesmachinery.com, Web: www.stilesmachinery.com.

IWF 2008 Booth #9140

CNC Router Line

For over 20 years and with thousand of machines worldwide,

Techno CNC Routers have

helped companies turn a

small investment into a

big return. Whether

you’re cutting large

sheets for nested based

manufacturing or small

intricate designs, Techno

has the affordable router

to meet your production and budgetary requirements.

Quality components such as, closed-loop servomotors, ball screws, THK rails come standard on Techno CNC

Systems. Complete jobs faster, with greater accuracy

using a Techno CNC Router.

For additional information, contact Roy Valentine,

Techno CNC Router Systems, P.O. Box 5416, New Hyde

Park, NY 11042, 800-819-3366/516-328-3970, Fax:

516-358-2576, E-mail: rvalentine@techno-isel.com,

Web: www.technocnc.com.

IWF 2008 Booth #6382

New Generation, 5-axis

CNC

Thermwood’s Model 90 represents a new generation, 5-axis CNC

machine for high speed trimming and modeling. The

state-of-the-art mechanical structure design created a

machine with unmatched strength, stiffness and performance.

All of which translates into high speed, accurate and

stable motions. The machine

was specifically designed

for the machining of

advanced aerospace

composites, high speed

machining of wood and

aluminum, in addition to

extremely fast trimming of 3 dimensional plastic parts.

The Model 90 also incorporates a new advanced, high

performance drives system. This translates into extremely

fast feed speeds, dramatically reducing cycle times. The

advanced machine design, along with the Gen2 control

system, is capable of handling motions that can dramatically

slow or cause shake in other machines.

M90 allows for full table coverage, and comes standard

with a 7 hp dual end spindle, solid aluminum table tops

with threaded inserts for fixture hold down, as well as the

patented impact-resistant head, which when impacted,

prevents or minimizes misalignment or mechanical issues.

Thermwood is the only major CNC router manufacturer

that designs and manufactures their own control; a control

so advanced it is used by various aerospace and

defense companies, and even NASA for some of their

most demanding applications.

For additional information, contact Cliff Crawford,

Thermwood Corporation, P.O. Box 436, Dale, IN 47523,

800-533-6901/812-937-4476, Fax: 812-937-2956, E-mail:

sales@thermwood.com, Web: www.thermwood.com.

IWF 2008 Booth #8326

SPE Booth #340

CNC Start-Up Package

If you’ve recently purchased or plan to purchase a CNC

router, Vortex Tool Company can provide a comprehensive

tool package for

new and used machine

start-ups. The Vortex

Tool start-up package

includes everything

from router and boring

bits to changing

stands, collets and

tool holders. The

Vortex staff will consult

with you to determine your router applications and

select a specific set of tools and accessories to get your

machine operating efficiently.

Most items are in stock for immediate

shipping.

At their facility in Schofield,

Wisconsin, Vortex Tool Company,

Inc. designs and manufactures

high-performance router and

insert cutting tools for the woodworking

and plastics industries.

The company produces tools with

cutting edges in various grades of

carbide, stellite, high-speed steel

and polycrystalline diamond, and

provides custom tool design, retipping

and sharpening services.

For additional information, contact

Mike Serwa, Vortex Tool

Company, Inc., 5605 Jelinek

Avenue, Schofield, WI 54476,

800-355-7708, Fax: 715-355-7353, Web: www.vortextool.com.

IWF 2008 Booth #8952

|