Polyfab Plastics & Supply, an ISO

9001:2000 company, offers a

wide range of highly diversified

products to meet their customers’

needs and has the ability to customize

to meet a variety of specifications.

9001:2000 company, offers a

wide range of highly diversified

products to meet their customers’

needs and has the ability to customize

to meet a variety of specifications.

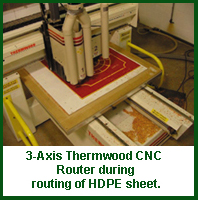

Polyfab, a full line distributor, offers a

wide range of fabrication services

including: CNC routing and sawing,

thermoforming, welding, hot air, extrusion,

sonic and butt fusion and an extensive graphics

department.

In the early 1970s Polyfab Plastics & Supply, Inc.

opened their doors in Springfield, Missouri by the company’s

current General Manager, Lowell

Miller. At that time, the company occupied

a small leased-space and

employed a small group of part-time

college students.

Over the years Polyfab has seen a

tremendous amount of growth as their

customer base and product capabilities

have continually grown and evolved. To

accommodate their consistent growth,

Polyfab began using automated equipment and moved

into their current headquarters of 60,000 square feet and

5 acres which evolved since

1988.

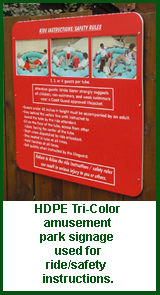

One area that Polyfab has

seen considerable growth in over

the past fifteen years is the signage

market. From amusement

park signage to depth markers

for their tank division, Polyfab

has developed an array of fabrication

and decorating techniques

to provide their clients with custom

signage to meet their growing

needs.

“Some of our customers’ designs start on a napkin,”

said Mike Miller of Polyfab, “others come as CAD drawings,

solid models or somewhere in between.”

After a project is

converted to a CAD

program it is turned

over to Polyfab’s

graphics department

where typically

a model is created

and submitted

for review by the

customer on larger

jobs. Upon approval

the signs are routed,

decorated and shipped with all the installation hardware,

and posts if necessary, for a turn key installation.

decorated and shipped with all the installation hardware,

and posts if necessary, for a turn key installation.

“Our success in the signage industry is due in large part

to King ColorCore® sheets with multi-colored layers. It is

easy to fabricate and has a consistent cap thickness. We

use many other materials, including solid King

ColorBoard®, polymer lettering and full-color printed materials

under clear acrylic protective covers,” said Miller.

“King ColorCore is a superior homogeneous sheet,

made with a unique state-of-the-art continuous process

called PolyFusion®.” said King Plastic Corporation sales

manager Lou Stegner. “It is manufactured to the highest

standards providing one of the most consistent cap thicknesses

and flattest sheets in the industry,” said Stegner.

manager Lou Stegner. “It is manufactured to the highest

standards providing one of the most consistent cap thicknesses

and flattest sheets in the industry,” said Stegner.

Stegner continued, “The sheets are easy to engrave and

machine, as the cap is approximately ten percent of nominal

thickness for high production speeds. Base materials

are FDA approved as are most pigments. King ColorCore

is made with high-impact-resistant polymer to handle

more abuse than conventional sign materials.”

Several standard

color combinations

are offered in 48” x

96” sheet with standard

thicknesses of

1/4”, 1/2” and 3/4”.

Custom sizes, colors,

thicknesses

and textures are

also available.

Fabricators can

work with King ColorCore

using standard woodworking tools. Carbide router

bits with 2-4 flutes are recommended. With a 1/2” diameter

router bit, feed rates of 12-16 feet per minute are

normal. Rates must be slower for material that is 1/2”

thick or thicker. Larger bits have higher tip speeds and

rpm adjustments may be necessary. Cuts are made with

a circular saw at 1275 rpm using a 50-70-tooth carbine

blade. Expect a similar feed rate. Edges may be finished

with a router and, if desired, a fine sandpaper. Use standard

fasteners with oversized holes. Drill pilot holes first,

followed by the oversized hole to allow for expansion and

contraction. Make plugs with a wood plug cutter for a finished

look.

are offered in 48” x

96” sheet with standard

thicknesses of

1/4”, 1/2” and 3/4”.

Custom sizes, colors,

thicknesses

and textures are

also available.

Fabricators can

work with King ColorCore

using standard woodworking tools. Carbide router

bits with 2-4 flutes are recommended. With a 1/2” diameter

router bit, feed rates of 12-16 feet per minute are

normal. Rates must be slower for material that is 1/2”

thick or thicker. Larger bits have higher tip speeds and

rpm adjustments may be necessary. Cuts are made with

a circular saw at 1275 rpm using a 50-70-tooth carbine

blade. Expect a similar feed rate. Edges may be finished

with a router and, if desired, a fine sandpaper. Use standard

fasteners with oversized holes. Drill pilot holes first,

followed by the oversized hole to allow for expansion and

contraction. Make plugs with a wood plug cutter for a finished

look.

When using printed images,

it is best to use a long-lasting

material and printing process.

Attach an adhesive-friendly

substrate with screws, then

attach the printed material

with adhesive, covering the

holes. Use a clear polymer

cover for a finished look and

extra protection.

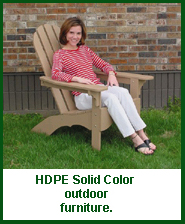

For

maximum

versatility,

standard colors are made to coordinate

with King ColorBoard®, a

high density polyethylene sheet

that is environmentally stabilized

for outdoor use. Its bright, primary

colors make it ideal for sign,

industrial, marine, playground

and

recreational applications.

Polyfab creates signs for

amusement parks, water

parks, golf courses and a

wide range of municipal

parks. Their wide range of

fabrication services also

enables them to supply

thermoformed polycarbonate

bubbles and other components

for playground equipment.

“We have also seen a dramatic

increase in interest in

outdoor living,” said Miller.

“King is able to supply

us with standard and

custom colors when we

need them and all their

material is here when

they say it will be,” said

Miller.

Polyfab also has a

thriving tank division

that is producing complete

and sometimes

complex tank systems.

They can design and fabricate an entire system including

pumps, filters, rectifiers for plating chemicals, the super

structure, lighting,

electrical, hoist systems

for raising and

lowering parts

into/out of the tank,

and liners for containment

in the

event of a leak or

damage to the tank.

After 38 years,

Polyfab Plastics continues

to be successful

as they continue

to grow and evolve. Polyfab creates products for a vast

number of needs in a variety of industries including: playground,

marine, food processing, electronic, aircraft and

surface finishing industries. Their products are distributed

throughout the United States and internationally.

Polyfab Plastics continues

to be successful

as they continue

to grow and evolve. Polyfab creates products for a vast

number of needs in a variety of industries including: playground,

marine, food processing, electronic, aircraft and

surface finishing industries. Their products are distributed

throughout the United States and internationally.

Founded in 1968, King Plastic Corporation is a leading

manufacturer of quality polymer sheets, slabs and massive

shapes including several products pioneered by the

company. Its polymers are sold worldwide through a network

of leading plastics distributors to customers who fabricate

products for the marine industry (King StarBoard®

brand), signage, food service, neutron shielding, construction,

industrial and other applications.

For more information, on Polyfab Plastics &

Supply, contact Mike Miller, 417-862-6512, Fax: 417-862-9080, E-mail: mdmiller@polyfabplastics.com, Web:

www.polyfabplastics.com.

For additional information on any of King’s products,

contact Lou Stegner, King Plastic Corporation, 941-493-5502, Fax: 941-497-3274, E-mail: sales@kingplastic.com,

Web: www.kingplastic.com.