As the number of brands

competing for consumer

attention at point-of-purchase

reaches an all-time high,

retailers are pressed to find ways

to maximize the use of merchandising

space and create a welcoming

environment for shoppers.

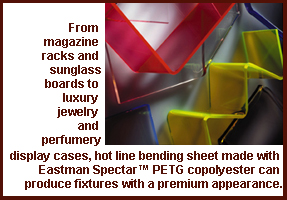

From magazine racks and

sunglass boards to luxury jewelry

and perfumery display cases, fabricators

are increasingly required

to handle a large number of retail

fixture requests on short notice.

are increasingly required

to handle a large number of retail

fixture requests on short notice.

For these professionals, adequately

responding to marketplace demands requires finding

new ways to enhance production efficiencies.

Hot line bending is a process

that many fabricators in the U.S.

and Europe use to produce fixtures

with a premium appearance.

Traditionally performed

with acrylic sheet, this process is

becoming revamped as fabricators

turn to alternative plastic

materials, such as PETG sheet.

Offering a variety of advantages for hot line bending,

including ease of processing and excellent cost-benefit

ratio, this clear, durable material can help fabricators

boost production efficiencies and meet the retail industry’s

needs for high-quality aesthetics and performance.

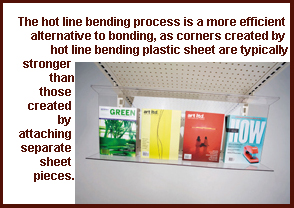

Hot Line Bending

Hot line bending is a fabrication technique for plastic

sheet used to create a variety of retail fixtures, including

magazine and brochure holders, shelving and high-end

displays. This process is a more efficient alternative to

bonding, as corners created by hot line bending plastic

sheet are typically stronger than those created by attaching

separate sheet pieces. This enhanced strength provides

displays with more durability to withstand the harsh

retail environment, decreasing the risk of breakage and

extending fixture lifespan.

When performing hot line bending, the fabricator heats

an area of flat plastic sheet until he can bend it without

any pull back. Depending upon the size of the heated

area, the sheet can be bent to a predetermined angle. To

optimize results, the heated area should be at least twice

the sheet’s thickness and no more than three to five times

the size. Once bent, the sheet can be placed in a cooling

jig to maintain the proper angle while the heated area

returns to a stabilized temperature.

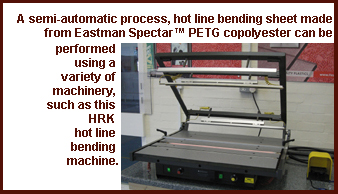

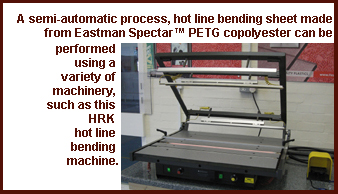

A semi-automatic process, hot line bending can be performed

using a variety of machinery. The industry standard

is a straight nickel-chromium (nichrome) resistance

wire heater, which is ideal for standard-sized sheets with

thicknesses of up to 6 mm. Other types of heaters can be

used for projects with special requirements, including very

thick or

large plastic

sheet

pieces.

Hot line

bending is

ideal for

fixture

projects

requiring

rounded

corners,

as the

process

does not

produce sharp or jagged edges. Currently, the look produced

by such rounded edges is growing in popularity

among retailers, who are increasingly incorporating more

modern, organic shaping and aesthetics into stores for a

warm, non-industrial consumer environment.

PETG Sheet and Production Efficiencies

PETG sheet offers a number of advantages for

fabricators

looking to maximize the efficiency of hot line bending

processes. Possessing a lower glass transition temperature

(Tg) than acrylic, PETG requires less heat to reach

process temperature. This property allows PETG sheet to

undergo

the heating

and

cooling

stages

more

quickly,

allowing

fabricators

to save

energy,

increase

production

rates

and

respond

quickly to project requests and tight deadlines.

fabricators

looking to maximize the efficiency of hot line bending

processes. Possessing a lower glass transition temperature

(Tg) than acrylic, PETG requires less heat to reach

process temperature. This property allows PETG sheet to

undergo

the heating

and

cooling

stages

more

quickly,

allowing

fabricators

to save

energy,

increase

production

rates

and

respond

quickly to project requests and tight deadlines.

The material’s inherent durability also allows PETG

sheet to be downgauged without sacrificing integral

strength. Downgauging further reduces the heat needed

to reach process temperature and bend the sheet, saving

even more energy and time during the hot line bending

processes. PETG sheet also does not require pre-drying,

helping to amplify these savings.

Eastman Chemical Company recently produced a study

on the hot line bending performance of PETG sheet compared

to other plastic materials. This study used a double-sided, straight nichrome wire resistance heater powered

to 200°C.

The study’s results, displayed in Chart 1, reveal that at

a 5 mm thickness, acrylic sheet takes a minimum of 65

seconds to bend and 229 seconds to cool, for a total processing

time of 294 seconds. Comparatively, 5 mm thick

PETG sheet takes a minimum of 55 seconds to heat and

143 seconds to cool, totaling 198 seconds. Comparing

these statistics, the use of PETG sheet for hot line bending

represents an average increase in time efficiency of 30

percent over acrylic sheet – a marked improvement.

The study also demonstrates that this efficiency could

be further enhanced when factoring in the downgauging

abilities of PETG sheet. To achieve the same durability as

5 mm thick acrylic sheet, PETG sheet can be downgauged

to a 3.5 mm thickness. This 28 percent material thickness

reduction corresponds to a related reduction in the time

and energy needed for hot line bending.

The study has further implications for fabrication efficiencies.

As PETG sheet requires less heat to hot line

bend, the material incorporates less strain over the course

of the bending process. Combined with PETG’s inherent

impact resistance, this lower strain level allows fabricators

to produce more durable retail fixtures, resulting in longer

fixture lifespan, minimized replacement needs due to

breakage and enhanced product safety.

bend, the material incorporates less strain over the course

of the bending process. Combined with PETG’s inherent

impact resistance, this lower strain level allows fabricators

to produce more durable retail fixtures, resulting in longer

fixture lifespan, minimized replacement needs due to

breakage and enhanced product safety.

These advantages also hold benefits for fabricators on

an environmental level. Sustainability is an increasingly

important issue for retailers, and top chains like Wal-Mart

and Marks & Spencer have developed and implemented

programs that define specific criteria for reducing overall

environmental impact throughout the supply chain. As an

interconnected part of this chain, fabricators are held

accountable for their use of resources. By utilizing PETG

sheet for hot line bending, fabricators can save material

and energy while also enhancing internal efficiencies, making

their businesses friendlier for the environment as well

as the bottom line.

As fabricators search for new ways to enhance hot line

bending efficiencies in order to keep up with demand for

quality retail fixtures, PETG sheet offers a number of benefits,

including superior impact resistance, ease of processing

and freedom of design. The material’s lower Tg

compared to acrylic sheet also allow fabricators to save

time and energy when hot line bending. These properties

enable the creation of more durable, long-lasting fixtures

for retailers and more efficient and sustainable production

practices for fabricators.

Written by Matthias Schönfeld, Specialty Plastics

Technical Service and Stefan Alves, Market Development

Manager, Specialty Plastics, Eastman Chemical

Company.