|

THERMOFORMING: Heavy Gauge Twin Sheet Forming

The twin sheet process is generally used to form structural, hollow thermoformed parts.

Twin sheet forming is a process of vacuum and compression forming two sheets of plastic simultaneously with a separate mold on the top platen and a separate mold on the bottom platen. Once the plastic sheets have been vacuum formed, they remain in their respective molds. While both sheets still remain at their forming temperature, the two molds are brought together under high platen pressures and the two sheets are bonded together wherever the mold-designed knit areas dictate. This will result in one single product with hollow areas and no secondary bonding required.The twin sheet process creates 3-dimensional parts with formed features on both sides. The parts are typically very strong, rigid and lightweight. Application specific to the material type, material gauge and machine configuration, foreign components or hardware may be inserted into the interior of the part during the forming process. Some of the hardware being inserted into twin sheet products today is wood, aluminum, steel, and foams. More advanced applications are now inserting tracking devises, measuring devices and mechanical sub-assemblies.

Twin sheet forming is a process of vacuum and compression forming two sheets of plastic simultaneously with a separate mold on the top platen and a separate mold on the bottom platen. Once the plastic sheets have been vacuum formed, they remain in their respective molds. While both sheets still remain at their forming temperature, the two molds are brought together under high platen pressures and the two sheets are bonded together wherever the mold-designed knit areas dictate. This will result in one single product with hollow areas and no secondary bonding required.The twin sheet process creates 3-dimensional parts with formed features on both sides. The parts are typically very strong, rigid and lightweight. Application specific to the material type, material gauge and machine configuration, foreign components or hardware may be inserted into the interior of the part during the forming process. Some of the hardware being inserted into twin sheet products today is wood, aluminum, steel, and foams. More advanced applications are now inserting tracking devises, measuring devices and mechanical sub-assemblies.

Typical twin sheet applications include: pallets, industrial dunnage, portable toilets, medical housings, surfboards, fuel tanks, air/ventilation ducts, electrical enclosures, recreational boats, cases, toys, marine products, doors, tables, spine boards and numerous transportation-related products.

The differences between twin sheet forming versus blow molding or rotational molding are typically cost-related. Twin sheet forming is very competitive with blow molding and much faster than rotational molding, especially with large, thick gauge products.

Versus Blow Molding

When comparing the blow molding process to twin sheet forming, tooling and machinery are usually more cost-effective for small to mid-size production runs. Each sheet can be a different thickness and/or even different colors. In some applications the twin sheet process will allow you to even use two different materials to form a single product. The twin sheet process allows more flexibility with parting (or bonding) line structure. The twin sheet process also allows the insertion of more elaborate hardware inside the final product before the two sheets are bonded together.

Versus Rotation Molding

When comparing the rotation

molding process to twin sheet

forming you get much higher

production rates, and have

the ability to use co-extruded

sheet, many more resin

types and you can design

more structural beams or

designs into the product.

Although the twin sheet

process has many advantages

over competing

processes, there are still

restrictions and many different

ways the twin sheet process

is accomplished. Further, different

types of twin sheet machinery may be

required for specific applications. This is

dictated by material gauge, material type,

material heating to cooling ratio, material hot melt

strength, bonding properties, material shrink, part size,

part design, the mechanics in tooling, cooling the interior

cavity, amount of pressure required, tolerance required of

bonded surfaces and tolerance of mold mating.

Single Oven Twin Sheet (SOTS)

The SOTS process utilizes the simultaneous heating of

two sheets, one above the other in a single oven (upper

and lower heater banks). There are two

different styles of SOTS forming:

one utilizing 2-sets of clampframe

and the other using 1-set of

clampframe. Different products

and/ or different applications

may lend themselves

to more efficient processing

benefits when utilizing

one over the other:

With A Single

Clampframe

Two sheets of plastic are

loaded into a single set of

clampframes. A regulated

probe is introduced to allow air

pressure to be applied between

each sheet while the vacuum is drawn

simultaneously on each mold to form a hollow

part.

With Two Sets of Clampframe (See Figure 1)

Two sheets of plastic are loaded individually in separate

sets of clampframes, one set placed a few inches above

the other. No regulated probe is required since the two

sheets are not clamped together. This technique provides

more options when considering the insertion of foreign

objects between the two sheets, along with more control

of the sag on each sheet.

When using the single

oven technique

only one side of each

sheet is being heated,

limiting the material

gauge to approximately

.160” per

sheet. This is dependent

on the different

types of material and

mold configurations

being utilized. Most

conventional machines

do not allow the ability

to insert something

between the two

sheets in the SOTS

process; however special

machinery and/or

tooling modifications

are available to accomplish this.

Double Oven Twin Sheet (DOTS)

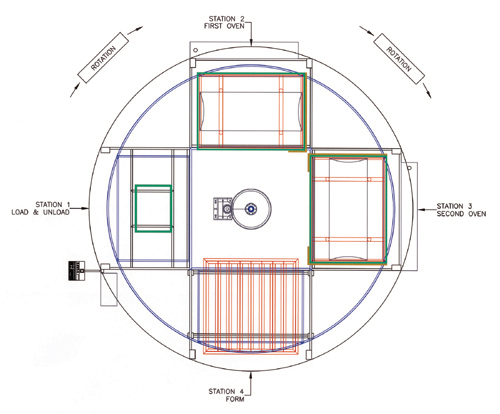

The DOTS process is most commonly done in a four station

rotary machine utilizing two sets of ovens (both with

upper and lower heating banks), often referred to as two

final heat ovens versus a preheat oven and final heat oven.

Double oven twin sheet machines heat the plastic on both

sides allowing the use

of thicker sheets or

starting gauges.

This process is most

commonly referred to

as a skip frame sequence

(see Figure 2).

- The first sheet is

loaded and indexed to

oven #1, while heating

in oven #1 the second

2nd sheet is being

loaded.

- Once the 2nd

sheet is loaded the

machine will index

again putting the 1st

sheet into oven #2

while the 2nd sheet is

moved into oven #1.

- After the 1st sheet is heated to its forming temperature

(in the 2nd oven) the machine will index again placing

the 1st sheet into the form station and the 2nd sheet into

oven #2.

At this point the first sheet is vacuum formed, then

released from the clamp frames and retained by its

respective mold. Simultaneously the 2nd sheet is being

heated to its forming temperature in oven #2.

-

The second sheet is then indexed into the form station,

is vacuum formed to the opposing mold, then compressed

with the first formed sheet resulting in a twin

sheet product. The DOTS sequence requires material heat

retention time to exceed or equal mold closure time.

-

The twin sheet part is then cooled and indexed to the

unload station.

In this type of machine and process every other index

will deliver a formed product. These types of machines

allow for much higher outputs by utilizing the simultaneous

use of each station.

Different Types of Twin Sheet Machinery

Each twin sheet machine design and configuration has

its advantages and disadvantages for different applications

and different end-users. A full assessment of product

requirements and production volumes certainly needs to

be evaluated in order to choose the correct machine and

machinery options in order to maintain a profitable operation.

The engineering department of the machinery manufacturer

should have the ability to design and specify the

machine and process to assist decision making.

Written by Michael P. Alongi, Sales Director for MAAC

Machinery Corp., manufacturers of a wide range of cut-sheet

thermoforming machinery.

For more information, contact MAAC Machinery Corp., 590 Tower Blvd.,

Carol Stream, IL 60188, 630-665-1700, Fax: 630-665-

7799, E-mail: sales@maacmachinery.com, Web:

www.maacmachinery.com.

|