|

Welding Spotlight

Hot Air Tools

The new S-LINE hot air welding

tools from FORSTHOFF feature

an ergonomic tapered handle

design, for a more comfortable

grip, with temperature controls and

power switch conveniently located at

the base of the handle. The new tools

continue to be service-friendly because of

the new generation of motors with significantly

increased carbon lifespan of more than

1,500 hours.

The new S-LINE hot air welding

tools from FORSTHOFF feature

an ergonomic tapered handle

design, for a more comfortable

grip, with temperature controls and

power switch conveniently located at

the base of the handle. The new tools

continue to be service-friendly because of

the new generation of motors with significantly

increased carbon lifespan of more than

1,500 hours.

The three new �S� line models - Quick-SE, Grand-SE

and Hot Air SE - will replace similar electronic versions of

the �L� line starting in Spring 2009. This change will also

be reflected in upgraded blowers for the automatic overlap

and tape welders.

For additional information, contact Bob Brunsman,

Abbeon Cal, Inc. , 123 Gray Avenue, Santa Barbara, CA

93101, 800-922-0977/805-966-0810, Fax: 805-966-7659, E-mail: bbrunsman@abbeon.com, Web: www.abbeon.com.

Rod & Welder

Drader stocks a range of welding rod and custom manufactures

numerous colors and types of plastic.

Customers

can send their

own resins to

ensure the welding

rod matches

the parent plastic

material exactly.

Drader�s

minimum order remains 10

pounds. Their welding rod

can be used with most fabrication type plastic welders on

the market today.

Customers

can send their

own resins to

ensure the welding

rod matches

the parent plastic

material exactly.

Drader�s

minimum order remains 10

pounds. Their welding rod

can be used with most fabrication type plastic welders on

the market today.

Injection Welder

Drader is also the manufacturer of the Injectiweld for

fabricating, prototyping and repairing thermoplastics. The

welder is easy to use and produces high quality welds.

Two unique features set the Injectiweld

apart from other plastic welders. A

hot tip melts into the parent

material eliminating the need

to scrape off the layer of oxidation

before making a

weld. Interchangeable

tips increase the

welder�s versatility, allowing welds ranging in size from

1/16� to 1/2� in a single pass. The second feature is its

automatic feed system. This allows control of the welder

with one hand and use of the other hand to hold the part

being welded. High quality welds are produced because

the unit injects a molten shot of welding rod into the weld

zone with consistent, repeatable pressure.

Drader is also the manufacturer of the Injectiweld for

fabricating, prototyping and repairing thermoplastics. The

welder is easy to use and produces high quality welds.

Two unique features set the Injectiweld

apart from other plastic welders. A

hot tip melts into the parent

material eliminating the need

to scrape off the layer of oxidation

before making a

weld. Interchangeable

tips increase the

welder�s versatility, allowing welds ranging in size from

1/16� to 1/2� in a single pass. The second feature is its

automatic feed system. This allows control of the welder

with one hand and use of the other hand to hold the part

being welded. High quality welds are produced because

the unit injects a molten shot of welding rod into the weld

zone with consistent, repeatable pressure.

For additional information, contact Bruce Lecky, Drader

Mfg. Ind., Ltd., 5750 50th Street NW, Edmonton, Alberta

T6B 2Z8 Canada, 800-661-4122/780-440-2231, Fax:

780-440-2244, E-mail: blecky@drader.com, Web: www.

drader.com.

Welders, Benders & Training

Ingenia North America�s manual butt welder model INGENIA

NA 15.20 S hand is

used for butt fusion of

thermoplastic sheets (e.g.

PVC-U, PE-HD, PP, PVDF)

either flat or at a 90�

angle. The machine will

weld widths of 1.5 meters

or 62 inches and up to 20

mm thick.

This is the ideal

machine for any shop to

fuse scrap or make small

tanks, etc.

This is the ideal

machine for any shop to

fuse scrap or make small

tanks, etc.

Automated Bending Machine

INGENIA NA automated bender model 20 BA, is a

robust all-round machine with a flexible range of application.

The bending cycle runs automatically, the main bending

parameters are stored in a database, which is linked to

the plc-control. While one bending zone is cooling, the

machine

automatically starts

the heating

of the next

bending zone simultaneously.

Machine widths can

vary from 1 meter to 3 meters and up to 25 mm thickness.

The machine is designed to fold-weld all semi-crystalline

thermoplastics as well as to bend amorphous thermoplastics.

The machine is also designed to bend U-Profiles. All

INGENEIA machinery is designed according the requirements

established by DVS e.V. and CEN standards.

INGENEIA machinery is designed according the requirements

established by DVS e.V. and CEN standards.

Welder Training

The Plastic Welding School has expanded the classroom

base to include The Malcom Company, Tiverton, RI, Star

Process Heat Systems, Farmingdale, NJ and also the

home classroom located in Belleview, FL. In addition, The

Plastic Welding School has expanded its curriculum to

include on-site training at the customer�s facility. This is

very beneficial as the employees work with the company�s

tools, in the company�s environment and with the company�s

material.

The spring classes will begin soon and enrollment is limited

to eight per class. All three courses: the two day introductory

class, the three day including extrusion welding,

and the 5 day advanced course will be taught at all three

locations and are hands-on.

For additional information, contact Larry Rowold,

Ingenia North America, 1010 Vermont Ave, The Villages,

FL 32159, 352-259-7103, Cell 630-319-3480, E-mail:

larry@rreworld.com.

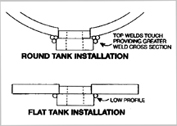

Stock Tank Couplings

Fabricated and molded tank manufacturers are finding

there is no longer a need for trips to a machine shop

because economical heavy-duty tank couplings, designed

for their application,

are now

available.

IPW

tank couplings

are easy to

install and are

sized to fit standard

hole saw

dimensions. They

have a shoulder

that gauges installation depth and provides for guaranteed

square installations on flat surfaces. The shoulder also provides

better weld strength and easy installation on round

tanks. The shoulder and the low profile design, combined

with thick crosssections, practically eliminate couplings

shearing off from side impact. The

thick cross-sections prevent the

splitting commonly seen with FPT

threaded couplings.

for their application,

are now

available.

IPW

tank couplings

are easy to

install and are

sized to fit standard

hole saw

dimensions. They

have a shoulder

that gauges installation depth and provides for guaranteed

square installations on flat surfaces. The shoulder also provides

better weld strength and easy installation on round

tanks. The shoulder and the low profile design, combined

with thick crosssections, practically eliminate couplings

shearing off from side impact. The

thick cross-sections prevent the

splitting commonly seen with FPT

threaded couplings.

IPW features sizes 1/2� through

4� from stock in natural HDPE,

black HDPE, natural PP and black

Type II (copolymer) PP. Eurogray

PP, PVDF, PVC and CPVC materials

and sizes 1/8� to 24� are now

available on request. IPW provides

full couplings when interior

piping is needed and for vertical

installations on domed tanks.

For additional information, contact

Phil Holt, Industrial Plastic

Works, 6220 Enterprise Drive,

Knoxville, TN 37909, 800-966-1460, Fax: 865-637-4540, E-mail:

sales@indplasticwks.com.

Hot Air/Hot Gas

Equipment

Laramy Products LLC has been manufacturing and supplying

thermoplastic welding and forming equipment for over

40 years. Their complete line of welders insures a model to

fit your needs and

your budget -

whether it be a

shop unit, field

application or for

nitrogen required

welds. A wide variety

of welding tips

and a wide range

of heat elements

are available to

complete your welding equipment.

welds. A wide variety

of welding tips

and a wide range

of heat elements

are available to

complete your welding equipment.

They also offer bending bars with an optional sword

attachment providing an inexpensive tool for heating thermoplastic

sheets to form bends.

Their fusion-type pipe welders with die sizes available

from �� through 4� and 16mm through 110mm provide

an efficient way to join PP, PE and Kydex pipe and fittings.

Laramy�s distributor base is global and they provide

100% inventory and same-day shipping.

For additional information, contact Sherry Stahler, Laramy

Products LLC, P.O. Box 1168, Lyndonville, VT 05851,

802-626-9328, Fax: 802-626-5529, E-mail: laramy@together.net, Web: www.laramyplasticwelders.com

Plastic Welding Equipment

For 60 years,

Leister Process Technologies

has been the

worldwide leader in plastic-welding and ho-air equipment,

with a wide selection of hand tools, accessories,

plastic-extrusion welders and

more. Headquartered in Sarnen,

Switzerland and with sales and service

centers in more than 90 countries, Leister is ISO

9001 certified, with all products and accessories manufactured

on its own state-of-the-art

premises. Swiss technology, unsurpassed

performance and quality,

and affordable prices

makes Leister the plastic fabricators�

first choice.

For 60 years,

Leister Process Technologies

has been the

worldwide leader in plastic-welding and ho-air equipment,

with a wide selection of hand tools, accessories,

plastic-extrusion welders and

more. Headquartered in Sarnen,

Switzerland and with sales and service

centers in more than 90 countries, Leister is ISO

9001 certified, with all products and accessories manufactured

on its own state-of-the-art

premises. Swiss technology, unsurpassed

performance and quality,

and affordable prices

makes Leister the plastic fabricators�

first choice.

The North American market is serviced by five

Authorized Master Distributors who are trained, tested

and approved to sell, service and support all Leister equipment.

Contact your local distributor for more information:

800-694-1472 (Western U.S.), 800-635-0384

(Midwestern U.S.), 888-807-4030 (Northeastern U.S.),

800-241-4628 (Southeastern U.S.), 888-438-6324

(Canada).

Welding Rod

New Image Plastics

New Image Plastics

is back in full operation offering the

largest selection of thermoplastic and engineering grade

welding/filler rod and can match and extrude welding rod

to meet customers� needs. Resin data sheets, real time

inspection reports and

manufacturer�s certifications

are also available

for your ISO requirements.

New Image extrudes

100% prime virgin

materials and can provide

Spec Sheets to

match parent material.

They can supply small diameter and large diameter rods,

rods for welding and custom print-to-part profiles.

For additional information, contact Jim Waring, New

Image Plastics Manufacturing, 2411 Locust Street South,

Canal Fulton, OH 44614, 330-854-3010, Fax: 330-854-6770, E-mail: newimageplastics@sbcglobal.net, Web:

www.newimageplastics.com.

Extruder Line

Plastic Welding Technologies (PWT) offers the new line of

Munsch Extruders. The extruders feature new brushless,

high output preheat blowers and smaller, dual display

temperature controllers. The extruders also feature heavyduty

custom-built drive

motors to withstand the

harsh conditions of continuous

use.

Munsch Extruders. The extruders feature new brushless,

high output preheat blowers and smaller, dual display

temperature controllers. The extruders also feature heavyduty

custom-built drive

motors to withstand the

harsh conditions of continuous

use.

The extruders have

higher extrudate outputs

and a lower price due to

improved manufacturing

techniques.

Munsch now makes all components of their extruders

in-house. This allows for greater quality control and better

product availability.

Larger models include a 2-year warranty on gearbox

and extruder heaters.

For additional information, in the west contact, Greg

A.Yaple at 800-635-6693, in the east contact, Rick

Conrad at 888-793-7333, PWT International, 4261

Business Drive, Cameron Park, CA 95682, E-mail:

sales@pwtworld.com, Web: www.pwtworld.com.

Plastic Welding Tools

Plastic Welding Tools

Ritmo�s

new extruder is equipped with a hydraulic motor

that allows you to perform welding with extremely high

output rates on large/thick

pipe fittings and

sheets. It is sold

with its own power

generator to make it

independent from other

power sources.

The RSB-60 is also equipped with an

extrusion output regulator, temperature control

safety system, display for temperature setting

and spotlight LEDs to illuminate the welding area.

It works with PP and PE rods of 5/32� and 16/34�.

This new hand-extruder is equipped with hydraulic hoses,

self-blower double temperature controller, turnable side

handle and a replacement 360 rotating Teflon shoe.

For additional information, contact Felix Vassallo, Ritmo

America, LLC, 300 Acuff Road, Lake Wales, FL 33859,

863-679-8655, Fax: 863-679-8685, E-mail: info@ritmoamerica.com, Web: www.ritmoamerica.com.

Hot Air Line

After 55 years of business,

Seelye

is still one of the leading

manufacturers of thermoplastic welders.

The Model 63 is a very popular welder for all levels of

expertise. The temperature on the SI-1005 and SI-1002 is

adjustable using the air regulator. Their 1167 includes a

self-contained air compressor and the only way to adjust

the temperature is by changing the heating element.

The FC Series are for people who want additional control.

They have a control board that enables the technician

to have more control over the temperature. By adjusting

the air flow on the 2001FC and the rheostat on the control

board you are able to achieve a more accurate temperature.

Unlike the 1167,

the FCP�s temperature is

adjustable and is controlled

by the rheostat on the control

board.

The 1197CH is the

welder for people who weld

everything from PP to

UHMW. Like the FC Series,

it has infinite heat control

settings and our patented

�Cool to the Touch Barrel.�

This safety feature allows the welder

to be approximately 900� F at the tip while leaving the

barrel cool to the touch.

The 1197CH is the

welder for people who weld

everything from PP to

UHMW. Like the FC Series,

it has infinite heat control

settings and our patented

�Cool to the Touch Barrel.�

This safety feature allows the welder

to be approximately 900� F at the tip while leaving the

barrel cool to the touch.

We are proud to announce that some of our most popular

thermoplastic welding tips are again available. We

have reengineered them to make them easier to use.

Please call us today to place an order for any one of our

thermoplastic welding tips including the famous: 1025

1028 Narrow body automatic speed tips, 1017 & 1018

Wide body automatic speed tips and 1024 Ribbon rod

automatic speed tips.

For additional information, contact Paige Bowen, Seelye,

Inc., 333C Enterprise Street, Ocoee, FL 34761, 800-258-

2936/407-656-6677, Fax: 407-656-5244, E-mail:

seelyeinc@aol.com, Web: www.seelyeinc-orl.com.

Full Line Welding Supplier

Wegener Welding LLC,

a renowned supplier of hot air, hot

air extrusion and sheet bending and butt welding machinery

is pleased to announce

that their location in

Chicago is now set

up to demonstrate

and supply

from stock butt

fusion

machines and

the relevant

band saws to

fabricate fittings

made

of thermoplastic

pipe.

air extrusion and sheet bending and butt welding machinery

is pleased to announce

that their location in

Chicago is now set

up to demonstrate

and supply

from stock butt

fusion

machines and

the relevant

band saws to

fabricate fittings

made

of thermoplastic

pipe.

The design of the welding machines allows for adaptation

to industry-specific demands. This includes machine

pressure ratings and pipe OD dimensions, as well as the

options of manual, data logging or full CNC controls. A

multi-purpose machine with additional IR technology is

also on

hand for

process

validation

purposes

of application-

specific

jointing

technologies.

With

easy

access to the two major Chicagoland airports, Wegener

is now set up to demonstrate sheet and pipe butt and

socket fusion technology as well as hot air and hot air

extrusion welders. In-depth welder training of the manual

technologies is also available. Wegener Welding enjoys

the challenge of designing and building specialty

machines for customers who need equipment and/or technologies

that are out of the ordinary.

purposes

of application-

specific

jointing

technologies.

With

easy

access to the two major Chicagoland airports, Wegener

is now set up to demonstrate sheet and pipe butt and

socket fusion technology as well as hot air and hot air

extrusion welders. In-depth welder training of the manual

technologies is also available. Wegener Welding enjoys

the challenge of designing and building specialty

machines for customers who need equipment and/or technologies

that are out of the ordinary.

For additional information, contact Dagmar Ziegler,

WEGENER Welding, LLC, 16W231 S. Frontage Road, Unit

#12, Burr Ridge, IL 60527, 630-789-0990, Fax: 630-789-1380, E-mail: dagmar@wegenerwelding.com, Web:www.wegenerwelding.com.

|