|

Plastic Pipe Spotlight

HDPE Pipe Fittings

Agru has more than 30 years

experience in injection molding.

The high quality raw material

is of the newest generation

of PPI and NSF listed material

and is compatible for heat

fusion with any pipe manufactured

from a similar or like

resin. Features of Agru’s pipe

fittings include corrosion, biological

and chemical resistant,

superior flow characteristics and lightweight.

For additional information, contact Robert Johnson,

Agru America, 500 Garrison Road, Georgetown, SC 29440,

800-373-2478, Fax: 843-527-2738, E-mail: salesmktg@agruamerica.com, Web: www.agruamerica.com.

Valve and Piping Systems

Asahi/America, Inc. introduced

its updated 12-page Thermo -

plas tic Valve and Piping

Systems catalog. A valuable

resource for engineers, plant

managers and distributors, the

catalog presents an overview of

Asahi/Ameri ca’s thermoplastic

fluid handling product lines,

capabilities for distributors,

engineers and installers.

The catalog highlights the many advantages of using

thermoplastic materials in fluid handling systems, including

their corrosion-resistant properties. Providing custo mers

with general information about Asahi/America’s products,

the catalog features specifications for thermoplastic valves,

pneumatic and electric actuators, high purity products,

industrial piping and double containment piping.

For additional information, contact Jeff Baker,

Asahi/America, Inc., 35 Green Street, Malden, MA

02148, 877-24-ASAHI/781-321-5409, Fax: 800-426-

7058, E-mail: asahi@asahi-america.com, Web: www.

asahi-america.com.

NSF Certification

NSF International announced that Charlotte Pipe and

Foundry Company’s RePVC™ (polyvinyl chloride) and

ReUze™ can now be added to the company’s list of products

certified by NSF International, an independent, not-for-

profit organization committed to protecting and

improving public health and the environment. Both piping

systems were inspired by the green and sustainability

industries.

According to Charlotte Pipe, there are three sources of

non-potable water: rainwater, gray water and municipally

supplied reclaimed water. Non-potable water systems are

great for applications that do not require water that has

been treated to drinking water standards.

NSF International’s certification for water piping systems

verifies that the

products meet all

applicable

requirements by

conducting thorough

testing and facility inspections.

ReUze, a purple CPVC piping system for distributing

non-potable water inside the building, is directly aimed at

increasing water efficiency. The line pipes are purple to differentiate

non-potable water from potable water. Nonpotable

water can be used to save building owners money,

relieve stress on already over burdened public agencies

and preserve a precious resource in applications such as

toilet and urinal flushing and process water.

RePVC is a PVC pipe that uses recycled content as the

center layer. It expands the market for recycled materials,

slows the consumption of raw materials and reduces the

amount of waste entering landfills.

For additional information, contact Towanda Long,

Charlotte Pipe and Foundry, P.O. Box 35430, Charlotte,

NC 28235, 800-438-6091/704-348-6685, Fax: 800-

553-1605, E-mail: tlong@charlottepipe.com, Web: www.

charlottepipe.com.

PVC Welder

One of the latest tools in Leister Process Technology’s

WELDPLAST line of hand extruders, the WELDPLAST S2

PVC meets the highest standards of functionality and

design.

Featuring a screw specifically

designed for PVC,

it is perfect for

use on PVC-U,

HDPE, LDPE and

PP membranes.

Measuring just

17.7 inches with a 3.8-inch diameter, this compact device

produces up to 5.95 pounds of extrudate per hour.

Like all Leister tools, the WELDPLAST S2 PVC is easy to

maneuver and comfortable to control due to its adjustable

air duct and pivoting handle. A multifunctional display

includes language selection, pre-set temperature settings,

maintenance notifications, time meters and the ability to

custom-program other settings.

Other key features include: a maintenance-free blower;

hot-air casing for heat protection; low-noise, high

power transmission; and a double-sided, non-twisting

wire feed.

WELDPLAST S2 PVC comes with a carrying case for

neat storage. Additional accessories include a tool rest

and complete welding shoes (fillet weld and V/X seam).

For additional information, contact a Leister Authorized

Master Distributor: Assembly Supplies (Western U.S.),

800-694-1472, Web: www.hotairtools.com; Heely-Brown

(Southeastern U.S.), 800-241-4628, Web: www.heelybrown.

com; Industrial Heat Sources (Midwestern U.S.),

800-635-0384, Web: www.industrialheatsources.com;

Malcom Company (Northeastern U.S.), 888-807-4030,

Web: www.malcom.com, STANMECH Technologies

(Canada), 888-438-6324, Web: www.stanmech.com.

Socket Fusion Tooling Kits

McElroy’s new Socket Tooling Kits are set to simplify the

work lives of contractors. The kits offer contractors an

opportunity to purchase a complete tooling set that

includes a Multi-Mc™

heater, heater sling,

heater adapters,

ratchet shears,

chamfer tools/depth

gauges, spare chamfer

blade and cold

ring tools.

Socket fusion is a

popular technique

for fusing high density

polyethylene

(HDPE) pipe fittings

in 1/2” copper tube size (CTS) to 4” iron pipe size (IPS)

pipe sizes (16mm to 125mm).

Eight kits are available that consist of equipment geared

to specific ranges of fitting sizes and heater voltage requirements.

The four size range options include a 3/4” to 2” IPS;

1/2” CTS to 2” IPS; 3” and 4” IPS; and 3/4” to 1 1/4” IPS.

After choosing the appropriate size range, contractors can

choose either a 120- or 240-volt Multi-Mc heater.

Large Fusion Machine

McElroy also offers the new MegaMc® 1600 four-jaw

machine which can handle a variety of pipe applications.

The four-jaw fusion machine has the power and finesse

to butt fuse high-density polyethylene pipe (HDPE) as

small as 20” to as large as 65” in diameter (500mm –

1600mm). The versatile

MegaMc is packed full

of features that give

the operator the

opportunity to easily

transport the machine,

as well as fuse fittings

onto large-diameter

pipes.

The MegaMc 1600 has 30,000 pounds of clamping

power in each of the four jaws. That force is used in clamping

and rerounding pipe for a high-quality fusion process.

When dealing with heavy large-diameter pipe, it’s critical

to have fusion force to overcome drag - unit offers 88,000

pounds of fusion force.

Critical components to the fusion process are upgraded

in the new machine. A facer with stronger internal workings

is 40 percent faster. An advanced digital heater control

provides better temperature control, while an automatic

hydraulic heater stripping device improves crucial

open and close times.

The fourth jaw is also completely removable, which

allows the operator the flexibility to fuse fittings onto a

length of pipe. The designed functionality of the machine

continues with four extendable hydraulic outriggers that

stabilize the machine on level and uneven jobsite locations.

One of the most important design elements of the

machine is the width. Measuring just 102 inches wide, the

unit fits on most flatbed trailers and can be road-shipped

without permit in most of the United States. The unit can

also be towed.

For additional information, contact Tyler Henning,

McElroy Manufacturing, Inc., 833 North Fulton, Tulsa, OK

74115, 918-836-8611, Fax: 918-831-9285, E-mail:

thenning@mcelroy.com, Web: www.mcelroy.com.

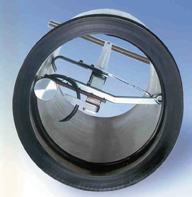

Bead Removing Tools

While the use of HDPE pipe in the water market finds

more and more acceptance, many experts in this field are

unaware that the removal of the internal bead not only

improves the performance

of the system, but

acutally is not that hard

to acccomplish.

Wegener Welding, LLC

carries an excellent tool

for the internal bead

removal for pipe diameters

OD 2” to 24”. This

range can be covered

with only three different

cutting heads, i.e. a single

head can cover a

range of sizes.

The tool is available with extensions to reach up to 65’

into the pipe. It has a very compact, sturdy and streamlined

design, is easy to use and requires practically no

maintenance. It’s German engineering at its finest.

For additional information, contact Patty Zitkus,

WEGENER Welding, LLC, 16W231 S. Frontage Road, Unit

#12, Burr Ridge, IL 60527, 630-789-0990, Fax: 630-

789-1380, E-mail: patty@wegenerwelding.com, Web:

www.wegenerwelding.com.

|