|

ROUTING: Routing & Trimming Polypropylene

Polypropylene is what many people mean when

they say “plastic” because it is the base of many

products and is capable of being fabricated by

many processes. From fiber to film, from injection molding

to thermoformed sheet, polypropylene is as versatile as it

is varied. It can be formulated to result in a wide

range of melt points, weights, stiffness and

machineability. Formulations can provide a substance

somewhere between traditional rubber and

conventional plastics. Other possibilities may be

filled or reinforced grades which offer good stiffness

and stability.

machineability. Formulations can provide a substance

somewhere between traditional rubber and

conventional plastics. Other possibilities may be

filled or reinforced grades which offer good stiffness

and stability.

One property of polypropylene, chemical or solvent

resistance, makes it ideal for tanks, vessels

and bottles used in the chemical industry. PP is

also used for clean room furniture and fixtures.

Some other auto interior and trim parts, shrouds,

covers, storage bins are all PP products which may

be trimmed or routed in the fabrication process.

Most PP products are machined on CNC routers.

Hand held electric or air routers do not normally

give satisfactory results. In most instances, PP is a

difficult material to work with because of its gummy

nature. It is always susceptible to reweldment or

wrap around of waste material on the cutting tool.

It can be challenging to obtain a proper finish on the

end product. Feed rates are critical for productivity

and cutting tool selection is critical for best results.

Anyone who has cut or trimmed anything but the

most dense and stable PP can attest to the above.

Machining PP is a continuous improvement process

often initiated by a basic trial and error process.

difficult material to work with because of its gummy

nature. It is always susceptible to reweldment or

wrap around of waste material on the cutting tool.

It can be challenging to obtain a proper finish on the

end product. Feed rates are critical for productivity

and cutting tool selection is critical for best results.

Anyone who has cut or trimmed anything but the

most dense and stable PP can attest to the above.

Machining PP is a continuous improvement process

often initiated by a basic trial and error process.

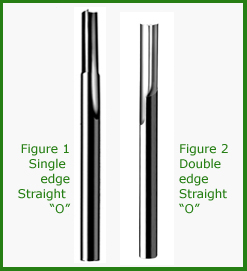

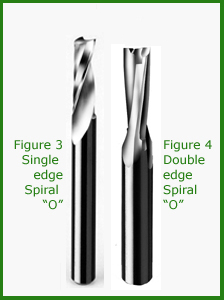

There are a few principals to employ when

machining polypropylene. Every

attempt should be made to cut large

chips. This can be accomplished by

use of slow helix tools shown in

Figures 1 and 2. Slow helix tools tend

to take a larger chip than conventional

helix tools and are available in single

or double flutes in both upcut and

downcut spirals. Here is where some

trial cuts should be made to determine

whether single or double flutes

and up or down spiral works better in

a specific application. A single edge

O flute, shown in Figure 3, may also be the best answer

for a particular job. Slow helix tools are also available with

a bearing pressed on the end of the cutting edge for guided

trimming operations if a CNC router is not available.

Because of the gummy nature of PP and the inherent heat

generated by cutting action,

high-speed steel tools are not

recommended. Solid carbide bits will outperform

high-speed steel, carbide tipped or diamond tools

and are the only type recommended for cutting PP.

High feed rates should be employed along with

lower spindle speeds. This will tend to abate reweldment

behind the cut and waste wrap around. Feed

rates should be increased until such time as the finish

is unacceptable. Spindle speed should then be

reduced until the finish is once again acceptable.

The process can then be repeated until the optimal

result is achieved. This process should be repeated,

then cataloged, for each unique setup.

lower spindle speeds. This will tend to abate reweldment

behind the cut and waste wrap around. Feed

rates should be increased until such time as the finish

is unacceptable. Spindle speed should then be

reduced until the finish is once again acceptable.

The process can then be repeated until the optimal

result is achieved. This process should be repeated,

then cataloged, for each unique setup.

One may want to consider a two-pass

process to optimize both feed rate and

piece part finish. If a tool changer is available,

the second pass can be taken with a finishing

tool such as shown in Figure 4. In all instances,

when the depth of cut exceeds the cutting edge

diameter of the tool by more than a factor of three,

multiple passes should be taken. When such is the

case, the second pass should be taken with the

same tool as the first cut.

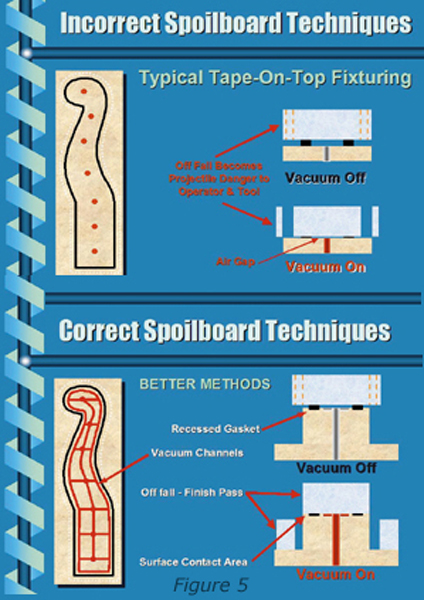

Fixturing also becomes very important to

achieve acceptable productivity. It is often recommended

that PP setups use gasket

tape to improve hold down.

Many times, however, the tape is just placed on the spoilboard

surface. When the vacuum is turned on, the foam

has no place to go but a flat compress. The result is the

tape loses its memory and allows the part being cut to

vibrate. Any inconsistency or warpage in the part will also

be exaggerated by the flattened gasket tape. Either situation

will facilitate tool breakage and less than achievable

finish. This problem can be mitigated by making a channel

in the spoilboard before applying the gasket tape.

Typically the channel should be one half the thickness of

the gasket tape. Grooving the spoilboard will enable the part

to achieve a better vacuum and will prolong both the life of

the tool and the gasket tape. See Figure 5 for a description.

Polypropylene can be cut effectively in a CNC router

environment. It is, however, a more complex environment

than we have previously discussed with routing and trimming

either PET or ABS.

For more information, click on the author biography at the top of the page.

|