|

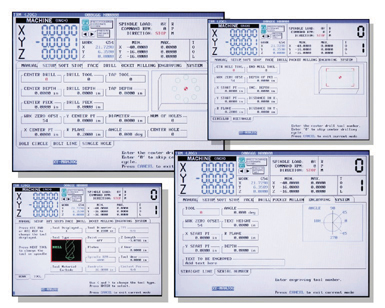

Programming Without G Code

For manual machinists ready to

make the transition to CNC, cutting

parts and creating part programs

has never been easier. With the new

Intuitive Milling System from Haas

Automation, Inc., it’s almost effortless.

This interactive, conversational

software guides the operator through

the steps required to machine a part,

from establishing tool offsets to

drilling bolt circles to engraving serial

numbers. An easy-to-read, full-color

liquid crystal display (LCD) presents straightforward information

for a variety of milling functions.

This interactive, conversational

software guides the operator through

the steps required to machine a part,

from establishing tool offsets to

drilling bolt circles to engraving serial

numbers. An easy-to-read, full-color

liquid crystal display (LCD) presents straightforward information

for a variety of milling functions.

Knowledge of G-code programming is not required to

perform such operations as setting tool and work offsets,

drilling and tapping and milling circular or rectangular

pockets. The operator simply chooses a function and is

then prompted to enter basic machining information such

as tool type, work coordinates, depth of cut or drill,

speeds and feeds, etc. When all the data has been

entered, a push of the Cycle Start button generates the Gcode

program and executes the desired operation. The

Recorder function can be used to save multiple operations,

for future duplication of the part.

From the Tool Setup menu, the operator enters tool type,

diameter and number of flutes, as well as workpiece material.

Speeds and feeds are then calculated automatically, although

they may be modified by the operator.

The Soft Stops menu allows limits to be

set on machine travels, to limit the risk

of a crash – a particularly useful feature

when, for example, there is a rotary

table within the work envelope. There

are also menu tabs for Facing; Drilling;

Pocket Milling and Engraving, and the

System menu contains the Recorder

function as well as information on any

alarms that may have been generated,

plus a message screen.

The Intuitive Milling System is standard on the Haas

TM-2 Toolroom Mill, a versatile vertical machining center

that combines the simple functionality of a manual mill

with the powerful flexibility of the Haas CNC control. The

TM-2 operates in three modes: manual, combined manual/

CNC and full CNC.

For more information, contact Scott Rathburn, Haas

Automation, Inc., 2800 Sturgis Road, Oxnard, CA 93030,

805-988-6922, Fax: 805- 968-6918, E-mail: srathburn

@haascnc.com, Web: www. haascnc.com.

|