|

Thermoplastic Welding Finds New Markets

Those involved in the thermoplastic

industry know that welding has been

around for quite

some time. At 50

years old, thermoplastic

welding

has come a

long way since its

early applications.

Today, many industries

are using

plastics to

replace traditional

materials offering

thermoplastic

fabricators and

welder’s new niche markets to pursue.

Today, many industries

are using

plastics to

replace traditional

materials offering

thermoplastic

fabricators and

welder’s new niche markets to pursue.

Some markets that are increasing their use of plastics

and their need for thermoplastic fabricators and welders

include agriculture, marine, electroplating, HVAC,

RV/Custom Coach and fire fighting industries.

In 1998, Seelye, Inc., manufacturers of hot air welding

tools, moved to Ocee, Florida, and

shortly thereafter started

DJ Plastics, Inc., a plastic fabricating company whose

main focus was to find welding markets that had not yet

been tapped. After months of research, the orange groves

held the answer. The agriculture industry was becoming a

major player for thermoplastic fabricators, especially

those located in the southeast and west coast. Most of the

bins the citrus growers use are made of HDPE and under

normal use, the bins crack and break. The most economical

choice for growers is to have the bins repaired by plastic

fabricators.

shortly thereafter started

DJ Plastics, Inc., a plastic fabricating company whose

main focus was to find welding markets that had not yet

been tapped. After months of research, the orange groves

held the answer. The agriculture industry was becoming a

major player for thermoplastic fabricators, especially

those located in the southeast and west coast. Most of the

bins the citrus growers use are made of HDPE and under

normal use, the bins crack and break. The most economical

choice for growers is to have the bins repaired by plastic

fabricators.

Another growing opportunity is the electroplating industry. For years, the electroplating industry used steel tanks.

Because of the high cost of repairs, the industry started

looking to thermoplastics. There are several styles of tanks

used in the electroplating industry such as nickel plating,

nitric acid, sulfuric acid and clean dip. Each tank is made

according to its use, varying in size, depth and length. The

tanks are commonly constructed of polypropylene (PP)

which is

more cost-effective

than steel

and much

easier to

fabricate

and repair.

The

RV/Custom

Coach

industry

has also

been

expanding

it use of

thermoplastic

structures and offers a lot of potential for thermoplastic

fabricators. The RV/Coach industry typically uses three different

types of tanks: gray water, black water and ice

chests; all are made out of either PP or Copoly. These

tanks are not for the novice fabricator. In addition to fabricating

the tank, baffles and valves must be constructed

and attached.

it use of

thermoplastic

structures and offers a lot of potential for thermoplastic

fabricators. The RV/Coach industry typically uses three different

types of tanks: gray water, black water and ice

chests; all are made out of either PP or Copoly. These

tanks are not for the novice fabricator. In addition to fabricating

the tank, baffles and valves must be constructed

and attached.

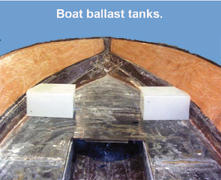

Another expanding market is the marine industry. Their

needs are similar to the RV industry and include water

holding tanks and tanks designed for ballast. The plastic

used in the marine industry ranges from PP to marine

grade formulation polyethylene.

needs are similar to the RV industry and include water

holding tanks and tanks designed for ballast. The plastic

used in the marine industry ranges from PP to marine

grade formulation polyethylene.

The fire-fighting industry is a major market for thermoplastics,

especially Copoly. Steel has been commonly used

for brush truck

and pumper

truck water storage

tanks, sizes

ranging from

250 gallons to

3,500 gallons,

but because of

rust and corrosion

they have

turned to thermoplastics.

Regardless of location, a fabricator is never too far from a

fire station and the possibility of opening up this quiet

market.

As thermoplastic fabricators, liability and warranty can

be a make-it-or-break-it component. A standard warranty

in the fabrication industry is a 30-day manufacturer’s warranty

against defect. This means that if the product fabricated

is defective in any way the manufacturer will repair

or replace the item. It is extremely important to note the

specific uses of the product in the warranty; and that the

warranty is null and void if the product was not used

where it was originally intended.

On the chance that a defective product affects other areas

of the customer’s

property, it is highly

recommended to

protect your company

and its assets.

Carrying an adequate

liability policy

will cover any possible

damages that

may occur if the

product you fabricate

fails.

Thermoplastics are replacing conventional

materials in

more industries

and

applications

everyday. For

thermoplastic

welders,

new opportunities

can be

found in the

agriculture,

marine, electroplating,

H VAC,

RV/Custom Coach and fire fighting industries to name a

few. Spend some timing identifying which of these industries

are in your geographic region and you may find new

opportunities for your business.

Carrying an adequate

liability policy

will cover any possible

damages that

may occur if the

product you fabricate

fails.

Thermoplastics are replacing conventional

materials in

more industries

and

applications

everyday. For

thermoplastic

welders,

new opportunities

can be

found in the

agriculture,

marine, electroplating,

H VAC,

RV/Custom Coach and fire fighting industries to name a

few. Spend some timing identifying which of these industries

are in your geographic region and you may find new

opportunities for your business.

Written by Paige Di Chiria Bowen, Marketing Manager for

Seelye, Inc., manufacturers and suppliers of a full line of

hot air thermoplastic welding tools supplies and accessories.

For more information, contact Paige Di Chiria

Bowen, Seelye, Inc. 333C Enterprise Street, Ocoee, FL

34761, 407-656-6677, Fax: 407-656-5244, E-mail:

seelyeinc@aol.com, Web: www.seelyeinc-orl.com.

|