|

Manufacturing Breakthrough at TMI

TMI has recently designed and installed a revolutionary Strip Press Feed at their manufacturing facility in Pittsburgh. The custom designed CNC machine replaces the entire manual process of measuring, cutting, punching, labeling and packaging flexible PVC strips from 4" wide up to 16" wide and from 0.040" thick up to .250" thick. The real breakthrough is the reduction in process time by as much as 90% and the increase in capacity by as much as 800%.

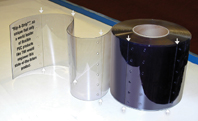

In addition to the faster turn-around time, customers can now order strips supplied in roll form utilizing the "Kiss-Cutting" process. Kiss-cutting is a process that leaves the individual strips on a continuous roll. This provides greater ease and handling during transport and minimizes the possibility of damage during shipment. The second option of pre-cut and pre-punched materials on the roll will be marketed as "RIP-A-STRIP™". TMI is the only company in the world that can currently provide "RIP-A-STRIP" in full rolls.

This state-of-the-art machinery allows them to ensure precision cut pieces. No "miss-cut" or "partially-cut" pieces; all the strips separate cleanly and evenly from the roll with no "double-cut" strips. The strips maintain a minimal and consistent gap and are available with the scrap material removed, leaving only usable pieces on the roll. Materials processed on this machine can vary from 4" to 16" wide and from 4" up to 16’ long.

In addition to the Press Feed Machinery, TMI has invested in two state-of-the-art CNC die cutting machines with single cut up to 42" by 62". This machine can be programmed to produce up to 1000 units per hour.

TMI is moving in the direction of Six Sigma. The investment in the new Strip Feed Press parallels the evolution to Six Sigma in three steps: (1) errors are eliminated right on the production floor and no human hands touch the strip surface, (2) the remote PC located in the production supervisor’s office allows management to observe "real-time" production and respond to any deviations from the computerized program entered for the day, and (3) TMI now has absolute control of production scheduling based on optimized cycle times and elimination of the human aspect of the process (such as vacation days, sick leave, etc.)

Since founding TMI, Incorporated in November of 1989, Jos Kleynjans, President, has always lived by the promise to his dealers and their customers of "Our Input for Your Success!"

For more information, contact Noel Olinger, TMI, Inc., 5350 Campbells Run Road, Pittsburgh, PA 15205, 800-888-9750 / 412-787-9750, Fax: 412-787-3665, Web: www.tmi-pvc.com.

|