|

The Benefits of Robotic Trimming

Flexibility, productivity,

safety,

quality and cost-competitiveness:

these are the attributes

that can make

or break the business

of a heavy gage thermoformer.

The ability

to have trimming

processes that deliver

all of these attributes

can greatly enhance

the thermoformer’s

success. The goal of this article is to familiarize thermoformers

with the attributes and benefits that can be

achieved using robotic trimming systems over the other

trimming choices available.

Implementing robotic trimming automation requires a

deep understanding of “path intensive” motion requirements

and

the other

supporting

technologies

required to

maximize

the benefits

that can be

achieved

with a robotic

trimming

system. Take

care to

select a

System

Integrator

that fully

understands

the requirements

of

trimming

applications

to take full

advantage of

the potential benefits. This article is based upon KMT

Robotic Solutions’ (KMT-RS) many years of success

working with thermoforming companies to implement

robotic trimming solutions.

Flexibility

The ability to easily program for a variety of parts,

to be able to add in new parts over time and to efficiently

implement part changeovers is key to the thermoformer’s

production flexibility. Making this efficient

requires a combination of off-line programming tools,

system calibration features and program management

tools that specifically address these flexibility

requirements. With these features in place, changeovers between parts can typically be implemented in

about a quarter of

the time it takes to

changeover a CNC

machine.

Flexibility also

comes from the ability

to reprogram for

part design changes.

KMT-RS provided a

production system to

one thermoformer

that used this equipment

to implement a

series of short prototype

part runs for their customer. This allows their customer

to work through an intensive product design change

period in a fraction of the time that it took them when the

parts were trimmed using trim dies. Now their customer is

demanding that all future part programs be implemented

with robotic trimming for prototyping and production so

that they get the benefits of the part change flexibility

available during the prototyping stage.

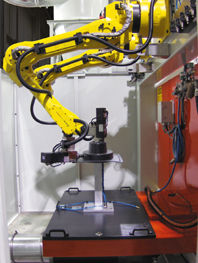

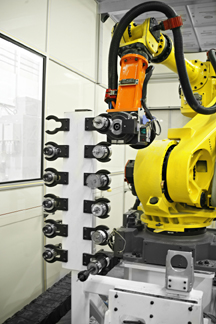

The ability to use a variety of tools on the same

robot is another type of flexibility that can be provided.

This can be more traditional with a variety of cutting

tools being available to an automatic tool change

routing spindle, or more advanced. An example of

more advanced tool change would be a robot dropping

off the routing spindle and picking up a compliant

knife to facilitate fine edge finishing.

Flexibility is also delivered through having a wider

range of motion with a 6-axis robot arm, providing

the ability to process a wide range of part sizes,

including taller parts. CNC machine pricing is heavily

influenced by

the Z stroke

required while

robots can

often process

tall parts at no

added cost.

Flexibility is

also available

with the option

of adding

capacity as

production

requirements

increase. For

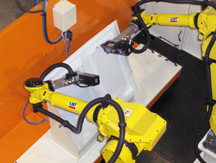

example,

adding another

trimming position

or another

robot arm to a

system can be

accomplished

to increase

throughput.

And the ultimate flexibility also

exists: if the need for the

robot in its current

process goes away, then

the robot can be retooled

and redeployed doing a

totally different process,

protecting your investment.

Productivity

Ease of changeover

part to part was mentioned

in the Flexibility

section. The time savings

over CNC changeovers

using a robotic system

equipped for fast

changeover results in less labor per changeover, less part

waste during set-up and more parts produced in a shift.

Another key attribute of productivity is the cycle time

achievable per part. The process used to cut the part primarily

governs the cutting speed, so CNC machines and

robotic trimming typically will not vary significantly in cut

time but the robot can implement faster tool changes and

Tool Center Point (TCP) calibrations than on a CNC and

make quicker motions between cuts, giving it a total cycle

time advantage. For example, spindle alignment can be

achieved automatically on the robot system within 90 seconds

while this process takes up to four times longer on a

CNC machine. Shorter per part cycle time plus faster worn

tool changes means more productivity per shift.

The ability of the robot to reach all around the part,

including from underneath the part, can impact the number

of set-ups required to trim a part. KMT-RS has customers

that have eliminated the second set-up required on

a CNC machine to process the underside of the part and

save the cost of the second part fixture along with increasing

their productivity.

Reliable operation is also a key to high productivity.

Today’s industrial robots have Mean Time Between Failure

(MTBF) over 90K hours and never take a vacation day. The

maintenance requirements for the FANUC robot arms are

minimal consisting of annual lubrication and replacement

of 4 D Cell batteries. In addition, the robot is able to protect

itself and its tooling with Torque Overload Sensing

(TOS), so it stops upon collision. This approach is superior

to the mechanical break-away methods used on CNC

machines and facilitates much quicker recovery from unexpected

events, again improving productivity.

Reliable operation is also a key to high productivity.

Today’s industrial robots have Mean Time Between Failure

(MTBF) over 90K hours and never take a vacation day. The

maintenance requirements for the FANUC robot arms are

minimal consisting of annual lubrication and replacement

of 4 D Cell batteries. In addition, the robot is able to protect

itself and its tooling with Torque Overload Sensing

(TOS), so it stops upon collision. This approach is superior

to the mechanical break-away methods used on CNC

machines and facilitates much quicker recovery from unexpected

events, again improving productivity.

Safety

Operating a thermoforming business safely is essential

to controlling risk and its associated cost. Keeping team

members separated from high speed rotating equipment

is a benefit of a robotic trimming solution implemented

correctly with appropriate solid guards. In addition,

removing team members from repetitive, manual trimming

operations eliminates a major source of repetitive

motion injuries and the

associated insurance

liability.

Quality

Robots deliver repeatable

processes with consistent

results. They don’t

get bored or distracted

and they can be programmed

to insure that

the right features get

trimmed into every part.

This is very important

when there are lots of

option choices that

impact the features to be

trimmed in a part.

KMT-RS has had experience with a range of plastic and

thermoformed parts that require tight tolerance trimming

that is challenging due to the part distortion or variable

shrink rates. To overcome this challenge, KMT-RS has

developed patent-pending AccuFind® sensing technology

that can be implemented to locate the part and specific

key features and make 3D offsets to the robot’s trim path

to the new position of the part and features. This unique

approach minimizes additional cycle time required, protecting

productivity while delivering part quality.

Cost Competitiveness

Reliable and repeatable processes lead to better control

of the manufacturing critical path, predictability and

reductions in manufacturing time, and more consistent

high product quality. This provides the opportunity for

the thermoformer to take a more aggressive pricing position

at less risk when going after new business. KMT-RS

has many customers that have revised their approach to

quoting projects based on their new economics with

robotic trimming and have won back business that was

previously lost.

Flexible Robotic Trimming, implemented effectively, can

offer your company the opportunity to improve process

throughput, have more reliable and repeatable processes,

improve product quality and consistency, remove your

employees from potentially hazardous jobs and increase

cost competitiveness. This can lead to a variety of benefits

for the business, including improved relationships with

customers, opportunities to win new business and

improved financial results. Consider how your business

can be impacted with the power of Flexibility, Productivity,

Safety, Quality and Cost Competitiveness, and create a

plan to add robotic trimming to your business model.

Written by Roberta Zald and Paul Schuch, KMT Robotic

Solutions, Inc.

For more information, contact Roberta

Zald, KMT Robotic Solutions, Inc., 1255 Harmon Road,

Auburn Hills, MI 48326, 248-829-28014, Fax: 248-829-2750, E-mail: roberta.zald@kmtgroup.com, Web: www.kmtrobotic.com.

|