|

Flame Polishing with H2O Gas

The

ultimate green machine allows you to

convert water to H2O

gas. The OWELD gas generator

system provides significant

improvements in safety, ecology

and cost of operation.

The

ultimate green machine allows you to

convert water to H2O

gas. The OWELD gas generator

system provides significant

improvements in safety, ecology

and cost of operation.

Safety: The OWELD system

generates gas on

demand to a maximum pressure

of 10 psi. OSHA restrictions

start at 15 psi, so

OWELD does not qualify

under compressed gas regulations.

End the cycle of

receiving, renting, transferring, storing, inspecting and

returning emptied bottles. Instead, just supply water.

Ecology and Quality: H2O gas generates no CO or

CO2 residue or carbon byproducts. So this clean heat will

leave no residue on your plastics. H2O gas is the ultimate

in clean burning gas. Operators initiate an on/off valve

ensuring no operator adjustment of the flame and providing

a very repeatable process. Just gas on and gas off

channeled through vinyl tubing from the machine to the

point of use, which can be 100’s of feet away.

Economy: The cost of operation is nearly 80% less

expensive than traditional bottled gases. ).

One machine

can generate gas for several torches operating continuously.

With 6 torches operating continuous you cost is

roughly $1.00/hr (plus a quart of water. OWELD gas generators

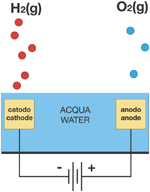

convert H2O into H2O Gas

via electrolysis (Fig 1). This

process is not new and neither

is OWELD, started in

1981.

OWELD is in an exclusive

class as it manufactures

machines capable of producing

larger amounts of gas for

industrial applications. A

single machine on wheels

can operate multiple torches

of the same or different configurations

(single, dual or multiple port tips).

The configuration of the flame can be as compact and tactical

or broad and robust as the application requires. There

are over 3000 OWELD systems generating clean H2O gas

around the globe in jewelry, plastics, brazing, soldering,

cutting and mechanical

heating applications.

One machine

can generate gas for several torches operating continuously.

With 6 torches operating continuous you cost is

roughly $1.00/hr (plus a quart of water. OWELD gas generators

convert H2O into H2O Gas

via electrolysis (Fig 1). This

process is not new and neither

is OWELD, started in

1981.

OWELD is in an exclusive

class as it manufactures

machines capable of producing

larger amounts of gas for

industrial applications. A

single machine on wheels

can operate multiple torches

of the same or different configurations

(single, dual or multiple port tips).

The configuration of the flame can be as compact and tactical

or broad and robust as the application requires. There

are over 3000 OWELD systems generating clean H2O gas

around the globe in jewelry, plastics, brazing, soldering,

cutting and mechanical

heating applications.

The H2O gas

offers many other

benefits. The ability

to direct a clean burning

flame, up to 6000ºF, into

any position or configuration

desired. The flame can

be targeted with pinpoint

accuracy to apply a precise

amount of heat to the

desired area. The flame is

fully repeatable 24/7.

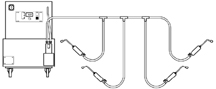

One gallon of water produces

more than 2100 gallons of

H2O gas providing enough

gas for multiple flame polishing

torches for nearly 4

hours of operation (Fig. 2).

One gallon of water produces

more than 2100 gallons of

H2O gas providing enough

gas for multiple flame polishing

torches for nearly 4

hours of operation (Fig. 2).

H2O Weld distributes, services and provides hands on

experience to configure the flame to match the customers’

requirements. Automated processes are an excellent

match for the OWELD system. To see a demonstration of

their process, search H2Oweld on www.youtube.com or

visit www.H2Oweld.com and www.automatedbrazing.com.

For more information, contact Tom Buckley, H2O

Weld, LLC, 2121 South 116th Street, West Allis, WI

53227, 317-670-1048, Fax: 414-546-9551, E-mail:

tom@h2oweld.com, Web: www.h2oweld.com.

|