|

Welding Spotlight

High Speed Torch

The Laramy Torch is an electrically-heated, variable gas flow

torch of proven design, featuring

6 new interchangeable

“Located Heat” elements for

welding temperatures from

450-1300°F. This high-production

torch offers complete versatility

of temperature and air

or inert gas selection for production

and speed welding on

all types of thermoplastics.

“Located Heat” elements are ceramic, clad with stainless

steel for greater shock and break resistance - plus

added protection against overheating and burnout.

“Located Heat” design concentrates heat output at the tip

end of the torch for cooler, more comfortable barrel temperature

while delivering higher gas temperature at the

tip from lower wattage elements. 250, 350, 450 and

550-watt. The elements are readily interchangeable in a

single small-diameter barrel for fast changeover and simplified

operation.

Two new high-temperature elements,

650 and 750 watts, make a

heat range of 850-1300°F available

for speedwelding of Polypropylene

and other high temperature materials.

These elements require use of a

long barrel, which is interchangeable

with the shorter length barrel used

with the lower wattage elements.

The exclusive Laramy High-Speed

Production Torch is available as a

basic welding torch, a complete outfit

or as a portable outfit.

For additional information, contact

Sherry Stahler, Laramy Products Co.,

P.O. Box 1168, Lyndonville, VT

05851, 802-626-9328, Fax: 802-626-5529, E-mail: laramy@together.net, Web: www.laramyplasticwelders.com.

Full Line Welding

Supplier

WEGENER Welding LLC is an international

supplier of high quality welding,

processing and testing equipment for

thermoplastic sheet and pipe fabrication,

repair and installation applications.

Their product range includes

hot gas hand welding systems

and accessories, extrusion

welding systems, sheet

butt welders and benders,

AC and DC spark testers,

plastic pipe band saws, pipe

butt and socket fusion

machines and tools, specialty

welders, filter

welding/embedding

machines and training and

education.

Recently they introduced the PST 100 AC spark tester

to check for voids and pinholes in thermoplastic welds and

non-conductive coatings and linings with a thickness range

of 1/8” to 1 1/4”. The lightweight and ergonomic design

make the PST 100 handy and easy to use. A wide range

of alternate electrodes and accessories are available for a

variety of different applications.

For additional information, contact Patty Zitkus,

WEGENER Welding LLC, 16W301 S. Frontage Road, Burr

Ridge, IL 60527, 630-789-0990, Fax: 630-789-1380,

E-mail: patty@wegenerwelding.com, Web: www.wegenerwelding.com.

Fusion Machines

McElroy’s Pit Bull® fusion

machines turned 15 years

old in 2011. The Pit Bull

range of fusion machines is

ideal for fusing thermoplastic

pipe in a variety of industry

and infrastructure construction.

Designed to be rugged

and reliable, the Pit Bull 14

is the flagship model and

butt fuses pipes from 1” IPS

through 4” DIPS. McElroy

celebrated the 15th anniversary

of the Pit Bull line by releasing the slightly larger 26

(2” IPS to 6” DIPS).

For additional information, contact Tyler Henning,

McElroy Manufacturing, Inc., 833 North Fulton, Tulsa, OK

74115, 918-836-9286, Fax: 918-831-9285, E-mail:

thenning@mcelroy.com, Web: www.mcelroy.com or

www.certifiedmcelroy.com.

Plastic Welding Videos

Drader Manu facturing is releasing

a series of videos

highlighting plastic

welding with

the Drader Injectiweld. Two

new videos show

viewers how to repair a damaged plastic slide and a broken

garbage cart. These instructive videos present the

capabilities of the Injectiweld and teach proper plastic

welding techniques. The videos are translated into 5 languages.

View the plastic welding videos on Drader's

YouTube channel at (http://www.youtube.com/user/DraderManufacturing).

Drader manufactures the Injectiweld for fabricating, prototyping

and repairing thermoplastics. The welder is easy

to use and produces high quality welds. Two unique features

set the

Injectiweld apart

from other plastic

welders. A hot tip

melts into the parent

material eliminating

the need to

scrape off the layer

of oxidation before making a weld. The second feature is

its automatic feed system. This allows control of the

welder with one hand and use of the other hand to hold

the part being welded.

Drader also stocks a range of welding rod and custom

manufactures numerous colors and types of plastic.

Customers can also send their own resins to ensure the

welding rod matches the parent plastic material exactly.

For additional information, contact Bruce Lecky, Drader

Mfg. Ind., Ltd., 5750 50th Street NW, Edmonton, Alberta

T6B 2Z8 Canada, 800-661-4122/780-440-2231, Fax:

780-440-2244, E-mail: blecky@drader.com, Web:

www.drader.com.

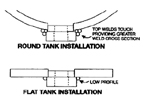

Stock Tank Couplings

Fabricated and

molded tank

manufacturers

are finding there

is no longer a

need for trips to

a machine shop

because economical

heavy-duty

tank couplings,

designed for their application, are now available. IPW tank

couplings are easy to install and are sized to fit standard

hole saw dimensions. They have a shoulder that gauges

installation depth and provides for guaranteed square

installations on flat surfaces. The shoulder also provides

better weld strength and easy installation on round tanks.

The shoulder and the low profile design, combined with

thick cross-sections, practically eliminate couplings shearing

off from side impact. The thick cross-sections prevent

the splitting commonly seen with FPT threaded couplings.

IPW features sizes 1/2” through 4” from stock in natural

HDPE, black HDPE, natural PP and black Type II (copolymer)

PP. Eurogray PP, PVDF, PVC and CPVC materials and

sizes 1/8” to 24” are now available on request. IPW provides

full couplings when interior piping is needed and for

vertical installations on domed tanks.

For additional information, contact Phil Holt, Industrial

Plastic Works, 6220 Enterprise Drive, Knoxville, TN

37909, 800-966-1460, Fax: 865-637-4540, E-mail: sales@ipw.us.com, Web: www.ipw.us.com.

Leister now Accepting

4-5mm Rod

You’ve asked for it and now Leister delivers. The FUSION

line of handheld extrusion welders has been used in plastic

fabrication for many years. For some time, users of the

FUSION extrusion welders have been asking for a Leister

extrusion welder that can use 5mm welding rod. Unlike its

predecessor, the newest FUSION 3C is available in a

model that uses 4-5mm welding rod and is a high-quality,

affordable solution to medium output extrusion welding.

Leister's FUSION 3C handheld extrusion welder boasts continuous and repeatable welding seam quality

and machine efficiency. This easy-to-handle

machine features an ergonomic design,

360° rotatable welding shoe, 180°

rotatable handle, twist-free rod

feed and motor protection

against cold-starts. Despite

its slim, ergonomic design,

this robust device produces

nearly eight pounds of extrudate

per hour (PP).

Similar to the FUSION 3C - but with a longer and more

vertical design - the FUSION 3 air-heated, handheld extrusion

welder is ideal for civil-engineering professionals

welding geomembrane liners. The FUSION 3 is also available

in 4-5mm rod feed.

For additional information, contact Daphne Mischel,

Leister USA, 1275 Hamilton Parkway, Itasca, IL 60143,

855-534-7837/630-361-9021, Fax: 630-760-1001, E-mail:

daphne.mischel@leisterusa.com, Web: www.leisterusa.com.

Welding Rod

New Image Plastics extrudes an

extensive list of thermoplastic and

engineering high performance plastics

for welding rod. They also extrude

customer provided resins and offer

additives to achieve a welding rod that

will meet your specific performance

requirements, backed by their manufacturer

certifications. Don’t take a

chance on a failed weld!

New Image has added four extrusion

lines to increase output and turnaround

time for your order.

For additional information, contact

Jim Waring, New Image Plastics Manufacturing, 241 Market Street West,

Canal Fulton, OH 44614, 866-789-WELD/330-854-3010, Fax: 330-854-6770, E-mail: plasticrods@aol.com,

Web: www.plasticweldingrod.com.

Mini-Electronic

Welder Kit

The Forsthoff Mini-Electronic is now

available in a kit. The kit includes

Mini-Electronic welder, 5mm round

adaptor, 3 sizes of push-on speed tips,

tacking tip, screwdriver, 9’ air hose, air

blower and storage box. This welder is

available without a

blower for use with a

compressed air

source using a regulator

and filter.

Threaded speed tips

are also available.

The easy-to-handle

Mini-Electronic is

particularly useful in welding plastic sheeting, pipes, fittings

and tank fabrication. Heat is variable from 68° to

1290°F and is kept constant electronically. An additional

control can also adjust airflow. Forsthoff also offers handheld

welders with built in blowers in the form of the Quick-

SE welder with ergonomic curved handle and the new

Tube-Q welder with traditional tube shaped handle. Kits

for the Quick-SE welder include an Overlap Welding Kit,

Flooring/Decking Kit and General Repairs Kit, which

include the appropriate accessories for defined job.

For additional information, contact Bob Brunsman,

Abbeon Cal, Inc., 123 Gray Avenue, Santa Barbara, CA

93101, 800-922-0977/805-966-0810, Fax: 805-966-7659, E-mail: bbrunsman@abbeon.com, Web: www.abbeon.com.

Canadian Master

Distributor

STANMECH

Technologies Inc. is a

leader in applications

involving plastics

forming and joining

methods including

hot air welding, extrusion

welding and

laser welding.

They supply Leister products including hand tools,

extrusion welders and accessories for plastic fabrication

and welding. The TRIAC S, their most popular hand tool,

offers steplessly adjustable temperature control from 20-700°C, is ergonomic and is easy to use. They stock a wide

range of accessories and nozzles for plastic welding including

tips for pendulum and speed welding as well as welding

mirrors for butt welding. Ideal for small projects,

touch-up work and repairs.

The compact, digitally regulated WELDPLAST S2 extrusion

welder is capable of welding PE (HD or LD), PP, and

PVC with up to 2.5 kg of extrudate per hour thanks to its

powerful drive system. The double-sided, twist-free welding

rod intake helps to prevent “bird-nesting” and the

adjustable, swivel-mounted handgrip makes the tool

ergonomic to use. A wide variety of welding shoes are

available and can freely rotate to ensure even the most

difficult pieces can be welded. The extruder is ideal for

welding pipes, containers or any large project.

STANMECH Technologies is the master distributor for

Leister Process Technologies in Canada.

For additional information, contact Sarah Fenwick,

STANMECH Technologies Inc., 944 Zelco Drive, Burlington, Ontario Canada L7L 4Y3, 888-438-6324/905-631-6161, Fax: 905-631-1852, E-mail: sfenwick@stanmech.com, Web: www.stanmech.com.

Mini Extruder

You’re not going to have much luck trying to weld

a tight corner in a two-foot container with a

three-foot extruder. Get all the power

of a real extrusion welder in a tiny

package. The MiniX is the smallest

extrusion welder on the market

but it has no problem keeping up

with the big guys. Totally self

contained, it has an integrated

onboard preheat air source and it

is small enough to be used with one

hand. Its preheat tube can be repositioned for bottom or

side mount use.

The MiniX uses a real auger screw for thorough material

mixing and consistent heat transfer - there are no air

pistons here. The extruder has a 2 lb/hr extrudate output,

can achieve temperatures up to 800°F, has digital speed

and temperature controls and weights under 10 lbs.

PWT offers a full range of thermoplastic welding and

joining equipment for the plastic fabrication market.

For additional information, contact Greg Yaple, PWT

International, 4261 Business Drive, Cameron Park, CA

95682, 800-635-6693, 530-676-3050, E-mail: info@pwtworld.com, Web: www.pwtworld.com.

Welding Rod

Village Plastics Co. is offering the

largest selection of thermoplastic

and engineering grade

rods for many welding

applications. They have

recently introduced a new

line of biodegradable PLA

rods that are used in threedimensional

printing applications.

Village Plastics offers welding rod that is consistent in

both diameter and shape. They extrude 100% prime virgin

materials with real-time inspection by laser micrometers.

Customer-supplied resins are always welcome and

custom color matching is offered. Resin data sheets and

manufacturers certifications are available upon request.

Unmatched quality, largest inventory, on-time delivery

and exceptional customer service is what sets Village

Plastics apart from other welding rod manufacturers.

For additional information, contact Connie Snyder,

Village Plastics Co., 3375 Barber Road, Norton, OH

44203, 330-753-0100, Fax: 330-753-6610, E-mail: sales@villageplastics.com, Web: www.villageplastics.com.

Bumper Repair Kit

A new automotive bumper

repair kit that repairs and

fabricates tabs and reinforces

cracks rather than replacing

the entire bumper is being

introduced by Malcom

Company, Inc.

Malcom’s Automotive

Bumper Repair Kit features a

compact 1200 watt heat gun

that provides heat up to

1150°F and 17.5 CFM air

flow, a wide slot nozzle, and

includes a proprietary mesh, and metal roller. Eliminating

the need to replace bumpers previously considered nonrepairable,

the repair employs the Heat €˜N Roll which preheats the plastic bumper and then rolls the mesh into the

softened bumper, encapsulating and reinforcing the

bumper.

For additional information, contact Don McHenry, Malcom Company, Inc., 590 Fish Road, Tiverton, RI 02878, 888-807-4030, Fax: 401-624-3081, E-mail: donmchenry@malcom.com, Web: www.malcomcompany.com.

North American Master

Distributor

Hapco Inc. is the North

American Master Distributor for BAK offering their

full line of heat welding

hand tools, hand and

industrial plastic extruders,

table heaters, benders and

folding machines, production heaters and blowers and all

accessories. Products can be shipped from either of their

Ohio or Texas facilities, to any location in the United

States, Canada or Mexico.

The management team at Swiss-based BAK, has over

24 years of engineering experience in

the creation, design, and manufacturing

of plastic welding products.

Hapco offers a single source contact

for all sales, repair service, and provides

in-house technical support to a

wide range of customers in a variety of

industries, namely plastics, industrial,

manufacturing, automotive, medical,

food, packaging and many more. Their

veteran and industry-experienced

technical staff provides the support

necessary that meets your expectations.

Their repair service is not limited

to the BAK product line, they provide

repair service to all major heat

tool manufacturers.

For additional information, contact

Mike Szugye, Hapco Inc., 390 Portage

Boulevard, Kent, OH 44240, 800-

345-9353, Fax: 330-677-8282,

E-mail: mszugye@hapcoinc.com,

Web: www.hapcoinc.com.

Enhanced

Website

Seelye Acquisitions, Inc. announced the

launch of their new and improved website,

www.seelyeinc-orl.com. You will

now find everything Seelye

offers with one easy click.

They have also added

Tefen fittings and tubing to

their e-commerce along

with their plastic welders,

welding rod and accessories.

You can also view all

of their “How to Weld”

videos on the website.

Distributors may now login

to view and order at their current

pricing level. Looking for a distributor for one of Seelye’s

plastic welders? Click on “Distributors,” find your state

and see everyone who is selling Seelye’s thermoplastic

welders, welding rod and accessories.

Whether you are looking for hot air/gas plastic welders,

custom fabrication, plastic or metallic machining or

water/air plastic fittings and tubing www.seelyeinc-orl.com

is your one stop shop for all things metal and plastic.

For additional information, contact Paige Bowen,

Seelye, Inc., 333C Enterprise Street, Ocoee, FL 34761,

800-258-2936/407-656-6677, Fax: 407-656-5244, E-mail:

seelyeinc@aol.com, Web: www.seelyeinc-orl.com.

|