|

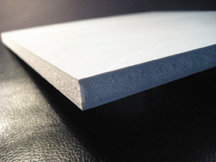

Composite Transit Flooring

Haysite Reinforced Plastics has recently introduced its

new grade Dura-Core 1000™. The new compression molded

composite panel combines high strength fiberglass

reinforced plastic (FRP) laminate skins with a lightweight

thermoplastic foam core material. The panel exhibits

excellent flame, smoke and toxicity properties (FST).

Engineered for use as a floor material in light transit rail

car interiors and multi-wheeled vehicle applications, the

unique resin system meets stringent transit industry specifications

for FST and is halogen free.

In addition to

these best-practice

safety standards,

Dura-Core

1000’s mechanical

properties

deliver significant

energy efficiencies

via its lightweight

core and additional

cost-efficiency’s realized via Haysite’s proprietary, onestep

compression molding process versus other methods

such as vacuum infusion.

In addressing the transit industry’s critical concern of

flame/smoke generation and smoke toxicity, Dura-Core

1000 has been tested using ASTM methods and provided

excellent results.

The material is fully compression molded in a ‘sandwich’

core construction to ensure against any separation/delamination

failure. The composite system’s physical properties

also offer excellent corrosion and chemical resistance; providing

very low moisture absorption and excellent resistance

to a variety of harsh weather environments.

Haysite implements a unique molding process that

saves time in production as all processing elements are

completed in a one-step proprietary method. This also

provides the flexibility to manipulate the composite if necessary

for intricate custom applications. This is essential

to rail car designers providing them with the ability to

strengthen the composite sheet in specific areas to meet

higher design and mechanical requirements.

Haysite is also exploring processing options that will

incorporate decorative, durable and skid-resistant finishes

that can be incorporated on the panels to provide rail car

designers with an entirely finished floor solution.

The material is available in standard sheet sizes of 36” x

72”, 48” x 60”, 48” x 96”, top/bottom rigid layers are .093–

.125” thick, thickness of .500” to 2.00” total thickness, custom

sheet sizes are available to meet all applications.

For more information, contact Anthony Lignetta,

Haysite Reinforced Plastics, 5599 New Perry Highway,

Erie, PA 16509, 814-868-3691, Fax: 814.864.7803, Email:

alignetta@haysite.com, Web: www.haysite.com.

|