|

Increase Production with Robotic Trimming System

Medallion Plastics, Inc., one of

the largest custom thermoformers

in Indiana, has

undergone tremendous growth in size

and diversification since the company

was founded in 1976. The company

started as a manufacturer of thermoformed

products for the recreational

vehicle industry and now supplies

quality products around the world to

industries such as communications,

defense, automotive, transportation,

recreational vehicle and manufactured

housing.

quality products around the world to

industries such as communications,

defense, automotive, transportation,

recreational vehicle and manufactured

housing.

Medallion needed a trimming solution

for its custom thermoformed parts that would be

more productive, reliable and cost-effective than the current

trimming system they were using. They wanted

improved repeatability and quality and reduced scrap and

labor costs.

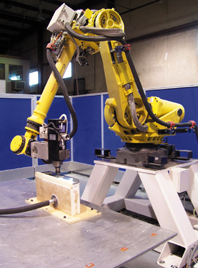

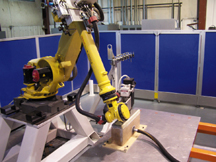

Robotic Production Technology (RPT) worked with

Medallion Plastics to

develop a large capacity

RoboTrim™ router trimming

system that could

accommodate the custom

parts that the company

needed to trim.

After reviewing Medallion’s

requirements, RPT

recommended an enclosed

RoboTrim router

trimming system with an

R-2000 robot and a

servo-controlled two position

table. This robot can

trim in a part as large as

100” x 49” x 21” tall. The servo table allows the operator

to load and unload parts while the robotic trimming takes

place inside the enclosed cell. This greatly improved the

productivity of these parts over their old trimming system.

Medallion Plastics to

develop a large capacity

RoboTrim™ router trimming

system that could

accommodate the custom

parts that the company

needed to trim.

After reviewing Medallion’s

requirements, RPT

recommended an enclosed

RoboTrim router

trimming system with an

R-2000 robot and a

servo-controlled two position

table. This robot can

trim in a part as large as

100” x 49” x 21” tall. The servo table allows the operator

to load and unload parts while the robotic trimming takes

place inside the enclosed cell. This greatly improved the

productivity of these parts over their old trimming system.

Medallion’s system included RPT’s TrimPro™ off-line programming

software and the Accuracy Enhancement software

to help accommodate the variance in parts. TrimPro

router software provides off-line simulation and programming

for FANUC robots used in RPT router trimming systems.

Users can import unique CAD models of parts, create

a work cell including machines, part transfer devices

and obstacles and teach robot paths to simulate the operation

and performance of a robotic application. Reach verification,

collision detection, accurate

cycle time estimates and other visual

system operations are simulated in

TrimPro’s unique graphical virtual environment.

Key features of the Accuracy Enhancement

tools are the ability to

automatically realign the router spindle

in less than one minute. The software

also gives the robot the ability to

automatically locate the part holding

fixture and orient the robot program

to that fixture’s exact position. This

software ensures the robot spindle is

aligned and that the exact fixture location

is known before the first part is ever run.

tools are the ability to

automatically realign the router spindle

in less than one minute. The software

also gives the robot the ability to

automatically locate the part holding

fixture and orient the robot program

to that fixture’s exact position. This

software ensures the robot spindle is

aligned and that the exact fixture location

is known before the first part is ever run.

The RoboTrim system also included a fixture ID system.With the fixture

ID system

the robot

knows what

fixture is on

the machine

and can automatically

call

up the correct

program for

that particular

part. By utilizing the fixture ID system, the Accuracy Enhancement

tools can also automatically be called into

action during the set up process.

In a demonstration of the system prior to installation,

RPT achieved a cycle time of less than four minutes to trim

an instrument panel versus the nine minutes needed from

their prior system. Since the system was installed in early

2004, Medallion Plastics has achieved a production

increase of 35 percent, quality has improved and they

reduced scrap and returned goods authorizations due to

human error.

Robotic Production Technology has been a turnkey

robotic systems solutions provider for 20 years. Industries

served include aerospace, appliance, automotive, composites,

construction, consumer goods, marine and plastics

industries. The company specializes in high path accurate

trimming applications such as router trimming, deflashing,

laser cutting and scoring and waterjet cutting.

For additional information contact Roberta Zald,

Robotic Production Technologies, 1255 Harmon Road,

Auburn Hills, MI 48326, 248-829-2800, Fax: 248-829-2750, E-mail: solutions@rpt.net, Web: www.rpt.net.

|