|

ROUTING: Routing With Air

Though simple in concept,

air routing is a

technologically advanced

process that has paid its

dues and is now the choice of

many manufacturers.

Pneumatic (or air) routing

has been a standard in many

shops and plants for

decades: its appeal only

seems to increase as technology

advances. Air routers are

simple machines that use

high-tech tooling to produce

parts that would be difficult

or unsafe to machine in any

other manner. They offer the

advantages of light weight,

easy-to-maneuver design, no

risk of electrical shock and

simple maintenance. Because

of these advantages, air routers are the router of choice

for many industrial hand routing applications.

Air routers are used to cut most machinable materials

used today including plastics, fiberglass or fiberglass/

wood composites used in the boat industry and aluminum

used in both the boat and aerospace industries. Their

applications include: cut-out routing through the use of a

template; trimming operations while

following a fixture; free-hand trimming

and, as technology grows, robotic

applications.

With the wide variety of materials

and applications in use and only a few

variations of the standard air router

available, fabricators must look to specialized

tooling to provide the best

solution for their cutting needs.

Tooling Requirements for

Air Routers

Router bits for air routers are specialty

tools. They look different, perform

better and, as opposed to standard

router bits, are designed specifically

for air routers.

Air router tools

have the following notable differences:

Air router tools

have the following notable differences:

- Longer Overall Length: Air router

tools must extend out to the collet,

through the nose bushing and out of

the guard. For this reason, the tools

are typically 3 1/4” to 4 1/2” long.

- Undersized Cutting Edge Diameter

(CED): Bits must pass through a

support bushing or bearing.Because of this, the CED is typically

toleranced (-0.001/-0.008). Since

hand routing is not normally an

operation that requires high

tolerance, this is an accepted

method of protecting the cutting

edge from damage due to

contact with the bushing or

nose guard.

-

Short Flute Fadeout: (B,

Drawing 1) This adds strength

to the tool by adding material

to the place which will

have the most amount of

stress. Short

fadeouts also

allow the bushing

to rest closer

to the actual

cutting surface.

-

Smooth, Large

Radius Cam

Fadeout: (C,

Drawing 1) Similar

to the flute fadeout, this adds

strength in a weak area of the tool. The

back of the cutting edge usually doesn’t see

much action, so this added material has

only a minimal negative effect on the cutting

action while decreasing the instances of

breakage.

-

Large Chamfer: (A, Drawing 1) This prevents damage

to the bearings, bushings and collet.

Air router bits offer the same variety of cutting geometries

as standard bits. Just like standard tools, air router

bits must be selected according to the material being cut,

finish and feed desired, and operator fatigue from hand

routing. Reduced operator fatigue is normally at the

expense of cutting tool life and this must be considered

during tool selection.

Some General Recommendations For

Tool Selection

- Single flute tools are very

aggressive. Use them

where high feed rates are

needed and finish is a

secondary concern.

-

Two flute tools are much

more stable in the cut,

easier to control and

produce a better finish.

- A premium finish can be

obtained by taking two

passes: one roughing

pass with a single flute

tool and a second finishing

pass with a three- or

four-edge tool, removing

a thickness of material equal to approximately 1/4 the

diameter of the bit.

- If a spiral is desired, use a downcut. This ejects the chips

away from the operator and can help hold the part in

place.

-

When cutting thin materials use a straight tool. This will

help stabilize the material.

Operating Conditions And Maintenance

The recurring problem of inconsistent finishes, inconsistent

tool life or router bit breakage plagues all users. This

is usually blamed on the tool because it is the item that is

most visible and costly in a routing operation. But there

are a multitude of other factors which are much less visible

and more likely to cause the problems listed above.

Air Pressure

In general, routers need 90 psi and 30 cfm of dry, clean,

lubricated air supply. If the router is receiving less than 70

psi or 20 cfm, then its usable horsepower is cut in half, as

well as exhibiting a drop in its rpms.

Router bits are designed for specific rpms and do not perform

well at lower spindle speeds. Air pressure should not

drop more than 10 percent from the static pressure when the

router is turned on. Too many quick disconnects, too small a

supply line or too many users on a line can cause these pressure

problems. If air pressure drops while the spindle is under

load, it may be an indicator that the router itself is in poor

repair and may need an overhaul.

Wrong Spindle Speed

Whether it is the result of low air

pressure, a router in poor condition or

just the wrong router, spindle speed

can greatly affect the performance of

router bits. The smaller the diameter

of the tool, the higher the spindle

speed needed to cut at peak performance.

Tools with 1/8” diameters work

extremely well in some of the older

turbine-style routers that spin up to

40,000 rpm.

Coolant

If cutting some plastics or aluminum

is a problem, use coolant. Many manufacturers

keep a block of beeswax or

barsoap at each routing station. The

operator dips the bit into the block

before each cut, greatly facilitating

chip removal and producing more consistent

finished parts.

Maintenance

As with any machine, maintenance is

critical. Air routers are extremely susceptible

to particulate damage due to

their operating environments and are

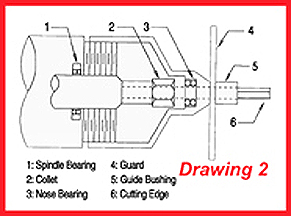

notorious for not having regular maintenance and overhaul performed on them. The spindle

and nose bearings (see Drawing 2) are shielded, but not

sealed.

They should be replaced a minimum of every 3 to

6 months. Vanes for the spindle should be replaced every

six months. Collets should be replaced every 2 to 6

months depending on material being cut and router use.

They should be replaced a minimum of every 3 to

6 months. Vanes for the spindle should be replaced every

six months. Collets should be replaced every 2 to 6

months depending on material being cut and router use.

Spindles are usually concentric to 0.0005” from the

factory. Regular use can cause this number to increase

up to 0.002”. A damaged or dirty collet, along with a

used nose bearing, can increase this and cause runout

at the tool tip to exceed 0.010”. When there is this kind

of collaborative runout -spindle, spindle bearing, collet

and nose bearing - the tool can have runout varying

from zero to 0.010” each time it is seated and tightened

down. What this translates to is when an operator is

doing a repetitive operation, he will see one tool perform

extremely well and get a maximum number of parts,

while the next tool will be difficult to push, give a poor

finished surface and cut drastically fewer parts. The bit

is always blamed, but is rarely the actual problem.

Operator Training

Air routing, without a doubt, is very “feel” oriented. An

experienced operator can tell when a bit is dull or when

performance of the tool and bit drop. New operators will

always break more tools than an experienced counterpart.

It just takes one hit of the tool on the fixture, one

time when a single edge tool gets away from the operator,

or one plunge too fast or erratic and the cutting edge

will chip. This chip will immediately degrade performance

and cause the tool to behave differently. This starts a

chain reaction and the entire cutting edge is corrupted in

a short time. When evaluating router and router bit performance,

do not forget operator competency.

Air routing has been around for a long time and will

continue to be an extremely viable method for trimming

and/or manufacturing parts. With the correct tooling

and an excellent maintenance program, air routers

are more reliable and comfortable to use than electric

routers in abusive or repetitive applications and can be

a cost effective alternative to CNC machines.

For more information, click on the Author Biography at the top of this page.

|