|

SOLVENT CEMENTING

Acrylic sheet can be easily joined to

itself or other plastic surfaces with commercially available solvent cements.

The proper cementing of acrylic sheet is a vital step in creating attractive,

high-quality displays that exhibit strong, unblemished joints. The following

information is given as advice on how to achieve these joints through the use of

solvent cements and polymerizable (two-part) adhesives.

Equipment and Materials

All cements should be used only in

well-ventilated areas with the proper protective equipment as recommended by the

manufacturer. Before using any solvent or cement, review the manufacturer's

Material Safety Data Sheet (MSDS) for that particular product. Viscous cement

can be used on hard to reach joints or for parts that do not fit together

precisely. Additional items likely needed for proper cementing include a solvent

cement applicator such as a needle-nose plastic container (used in capillary

cementing), pins or wire brads, and a dip or soak pan (used in dip or soak

cementing). Forms, clamps, and weights may also be needed.

SOLVENT CEMENTING

General Procedures

Follow these basic precautions when working

with acrylic solvents: work in a well-ventilated area and do not smoke. Some

solvents are highly volatile and may be flammable. Always protect skin from

contact with solvent cements. The ideal temperature for cementing acrylic sheet

is between 70° and 75°F. Do not attempt to cement in room temperatures

under 60°F or over 100°F. Be sure to follow manufacturer's safety

recommendation for equipment and materials used with acrylic

sheet. Preparation

Always prepare the area to be cemented.

Edges must be cleanly cut and properly machined. Melted or chipped edges could

be the result of using a dull blade during a saw cut. Contact between a chipped

or melted edge and the solvent cement may cause crazing (the appearance of tiny

cracks in the part). Finish all rough edges with a jointer, shaper or edge

finisher. If finishing on these machines is not possible, wet-sand the edges

with a flat surface or block.

Do not polish edges that are to be

cemented. Polishing produces a convex edge with rounded corners and results in

an unsightly, weak joint. Flame-polished edges will usually craze when contacted

with solvent cement.

Crazing can also occur if internal stresses

from fabrication are high. To eliminate such stresses, anneal the piece at

180°F (80° C). When annealing, the heating and cooling time, in hours,

should each equal the material thickness in millimeters, up to 6mm. For example,

a 3mm-thick sheet (.118-inches) would be heated for three hours, then cooled

gradually for an additional three hours.

For thin sheet, heating time should be at

least two hours. It is not necessary to heat any piece for more than six hours.

Note that each hour of heating time requires a corresponding hour of cooling

time. Capillary Cementing

Capillary cementing, the most popular form

of joining acrylic sheet, works because of the ability of a low-viscosity,

solvent-type cement to flow into a joint gap by capillary action. Properly done,

capillary cementing yields a strong, transparent joint.

Be certain all parts fit together properly.

Then join pieces with masking tape or clamp in a supporting jig to hold them

firmly in place.

When solvent cementing acrylic sheet, keep

the joint in a horizontal plane. Solvent cement flow can be improved by spacing

the two edges with shims. Use .004-inch shims with sheet 1/4-inch or thinner and

.008-inch shims with sheet thicker than 1/4-inch. Insert shims every two feet

for long edges.

Let the cement soak into the edges 45 to 60

seconds, for sheet thicknesses less than 0.236-in., before removing the shims.

Thicker sheet requires less time. Apply a small amount of pressure 0.7 to 1.4

lb./sq. in. (50 to 100 gr./sq. cm.) for three minutes, until the joint is set.

Apply pressure carefully, as the joint area will be soft.

If the cement does not flow completely into

the joint, tilt the vertical piece very slightly, about 1 degree, toward the outside.

This should allow the solvent to flow freely into the entire joint and tilt the

piece back again for a square corner.

The initial bond forms in five to 10

seconds. Wait three hours before subsequent processing. High strength is reached

within 24 to 48 hours. Strength of the joint will continue to build over several

weeks.

Dip or Soak Cementing

Pour a moderate amount of solvent cement

into a dip or soak pan. Dip the edge of one of the pieces to be joined into the

solvent. Only dip the edge. Exposing too much area to the solvent will result in

a weak, slow-setting joint.

Thin sheet should remain in the solvent for

20 seconds. Relatively thicker material should remain for 30 seconds. The time

varies for different solvents and bond strength requirements.

Remove and hold the sheet at a slight angle

to allow excess solvent to drain off. Carefully and quickly place the soaked

edge, precisely in place, on the part to be joined. Hold together for 30 seconds

without applying pressure. This allows the solvent to work on the surface of the

piece that was not dipped.

After 30 seconds, apply slight pressure to

squeeze out air bubbles. Too much pressure will squeeze out the cement.

When the pieces are joined, place in a jig

or clamp to maintain firm contact for 10 to 30 minutes. Do not allow the parts

to move during this critical time.

The initial bond forms in five to 10

seconds. Subsequent processing can be carried out after three hours. A high

strength bond is achieved in 24 to 48 hours, with additional strength continuing

to build for several weeks. Viscous Cementing

Use viscous cement to join parts that

cannot be easily cemented by capillary or soak solvent methods, because of

inaccessible joints or edges that do not fit together well. Viscous cement is

thick and will fill small gaps to make strong, transparent joints where solvent

cements cannot.

Remove the paper masking around the joint

area. Carefully apply a bead of cement to one side of the joint using a brush,

spatula, or cement applicator. Gently join the pieces together as in soak

cementing.

Viscous cements are commercially available

or can be made by dissolving chips of clear acrylic sheet in a small amount of

solvent. Let solution stand overnight in a tightly covered container.

Solvent-resistant tape, such as #685

Specialty Tape from the 3M Company may be applied to protect the area around the

joint. Remove it carefully after five minutes while the cement is still wet. Do

not touch the parts during the critical first three minutes or the joint will

not hold. The part can be moved, carefully, after ten minutes.

POLYMERIZABLE CEMENT

The following information is given

regarding the use of chemically reactive, two-part polymerizable cements, such

as Weld-On 40™.

Two Component Adhesives

Polymerizing adhesives are polymers

dissolved in monomers, which cure when a hardener is added. The cure is brought

about by a chemical reaction.

Polymerizing adhesives fill better,

imposing fewer demands on the fit and accuracy of parts. These adhesives must be

used when strength and resistance to environmental conditions are required.

Other two-component adhesives like epoxy

resins, isocyanates (polyurethane), phenolics, and aminoplastics are not

suitable for bonding acrylic sheet to itself or other materials because the

adhesion is very low. Equipment and Materials

A flat working surface is needed. Cover

work area with glass or polyester film. Strong ventilation or vapor removal is

necessary, as solvent vapors are heavier than air. The easiest method for

applying two-part polymerizable cement is to utilize a cement dispensing gun.

These devices automatically mix both cement components, from replaceable

cartridges, and permit relatively easy application through an applicator tip. If

a dispensing gun is not used, then a weigh scale, mixing containers, a vacuum,

and applicators are necessary. The weighing scale should have an accuracy of one

gram for weighing out the adhesive. Use round beakers made of glass,

polyethylene, or other materials that are insoluble as a mixing vessel. Glass or

polyethylene rods should be used for stirring small amounts.

The vacuum chamber is a small metal, glass,

or plastic chamber that can hold a beaker of the adhesive under a vacuum

pressure of -11 to -12 psi. A vacuum pump, capable of evacuating the vacuum

chamber to a vacuum pressure of -11 to -12 psi, is also needed. Disposable

syringes for applying the adhesives are required as well.

Jigs and fixtures are used repeatedly as

gluing jigs in mass production. Parts can be held with clips, clamps, lead

weights, or vacuum. Sealing of the joints to contain cement can be achieved by

using #685 Specialty Tape from the 3M Company. Area Bonds

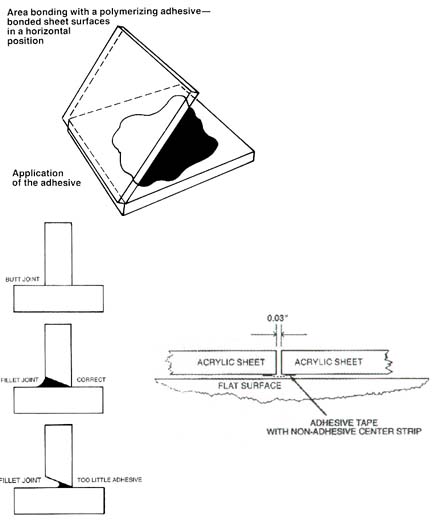

Area bonds may be produced either

horizontally or vertically. Thin sheets and thick blocks can be bonded

horizontally. Blocks can be bonded vertically.

For horizontal bonding, the degassed cement

(bubble-free) is poured on the panel approximately one-third the distance from

the edge of the part. The adhesive may be held in at the base with adhesive

polyester tape. Any bubbles formed while the adhesive is poured should be

removed. Starting from one edge, the top plate is placed in such a way that the

adhesive moves evenly between the plates.

With thin sheets, the relatively high

viscosity of the adhesive is sufficient to prevent the cement from being

squeezed out from the area being bonded by the weight of the cover.

Thick blocks should be separated

approximately 0.050-inches from the base by suitable spacers (polyethylene

cords).

If bubbles form while the cement is

applied, suck them out with fine capillaries while the adhesive is still soft.

Bubbles can also be extracted by pricking them with a fine steel wire and then

pulling them out at high speed. This technique is most suitable when bonding

large areas.

With vertical bonding, space the sheet or

blocks with a soft elastic cord so as to create a chamber at the top. The

prepared adhesive is then poured into the chamber.The minimum thickness of the

chamber is .060 to .080-in. This allows the cement to flow without causing

bubbles.

Vertical bonding has several advantages. An

adhesive with bubbles can still be poured because the bubbles will rise to the

top. Since the adhesive area is thicker, block with variations in thickness can

be bonded. Difficulty in placing the top plate (the horizontal method) is

eliminated, and adjoining surfaces may be covered with adhesive polyester film.

As the cement sets (still soft), the film can be removed with any remaining

cement. Butt Joints

To create butt joints, fix panels to a flat

support. Leave gap of at least .030-inches between the panels. Seal the

underside and face of the gap using strip adhesive tape with a non-adhesive

center strip. Using a syringe, introduce the two-part cement on the one open

side of this joint. Avoid bubbles.

The shape of the bonding gap depends

primarily on the thickness of the panels that will be butt jointed. V-butt

joints with a 60° aperture angle provide the highest tensile strength (Table

1), but aperture angles of this size are only practical when the sheets are

thin. For thicker sheet, smaller angles are recommended.

Glue Line

Sheet thickness Seam Aperature Minimum

Thickness

in Inches Angle In Inches

Approximately Butt joint with

.030-inches

.220-inches single V groove -30°

Approximately Butt joint with .030 to

.060-inches

1.25-inches single V groove -15°

The shrinkage of the adhesive during

polymerization and heat conditioning is approximately 15 to 20 percent by

volume. To prevent a concave surface, the gap should be sufficiently overfilled

with adhesive.

T-Joints

Bonding must be done in suitable jigs to

ensure that the bonding materials are fixed during bonding and the cure.

When creating T-joints, spacing the bonding

gap uniformly is difficult, especially when the adhesive joints of thin

materials are long. In addition, there is an adhesive bead on either side of the

joint. Solvent cements are better for bonding thin sheets with a blunt edge. A

beveled edge is generally useful for two-part polymerizable adhesives because it

allows one sheet's edge to be placed directly on top of the other sheet's

surface.

In order to produce a strong, attractive

joint, the bottom sheet should extend slightly past the edge of the vertical

piece to support a full bead of adhesive. After curing, the excess can be

machined off and the joint sanded and buffed.

Finishing the Adhesive Joint

A bonded part should be heat conditioned

(annealed) before finishing the adhesive joint. If not, it could form

constrictions when it is later heat conditioned. These constrictions will impair

the bond strength. Excess hardened cement or protruding edges can be effectively

removed using a stationary router equipped with a carbide tipped bearing flush

trim bit.

The finished surfaces can be sanded with

fine, wet, abrasive paper or fine steel wool then polished, to produce higher

optical quality bonds.

The amount of adhesive used in the joint

should be controlled so that only a little of it projects from the joint after

heat conditioning. This helps keep finishing work to a minimum.

| SOLVENT CEMENTING TROUBLE-SHOOTING GUIDE |

| Problem | Cause | Solution |

| Bubbles in Joint | Uneven Surface | Ensure edges are smooth and free of machining marks.

Check joint preparation for squareness.

Use shims to provide an even gap.

Use viscous cement. |

| Crazing | Stresses in material | Ensure edges are free of chips or melting.

Anneal areas near line bends.

Allow cement joints to cure for at least 24 hrs. prior to flame polishing.

Use water when sanding edges.

Use proper ventilation when cementing to eliminate trapped vapors. |

| Hazy, White Cement Joints | Water in the cement

Fast evaporation of cement | Replace Cement.

Reduce evaporation rate by adding glacial acetic acid (1-3%). |

| Weak Joints | Uneven surface

Cement problem | Check edge preparation for squareness.

Use viscous cement.

Check cement storage methods.

Solvent evaporation can change cement properties.

| | Whitening of Joints Over Time | Small gaps in joint or small grooves/machining marks in edge of sheet that allow excess cement to pool in the joint | Ensure edges are square and gaps between pieces are even. (use shims and weights if necessary). Ensure edges are smooth and free of machining marks. |

NOTE: Acrylic sheet is a combustible

thermoplastic. Precautions should be taken to protect this material from flames

and high heat sources. The information and statements contained herein are not

to be taken as warranty or representation for which CYRO assumes legal

responsibility nor as permission, inducement, or recommendation to practice any

patented invention without a license. Users should undertake sufficient

verification and testing to determine the suitability for their own particular

purpose. Be sure to follow manufacturer's safety recommendations for equipment

and materials used with acrylic sheet.

Written by Grant LaFontaine, Sheet Products

Technical Service Manager, CYRO Industries.

For more information, contact

CYRO Industries, P.O. Box 5055, Rockaway, NJ 07866, 800-631-5384, Fax:

973-442-6117, In Canada: 800-268-4743, Web: www.cyro.com. CYROIndustries will be

speaking on the above subject at the Septermber 12, 2000, International Plastics

Fabricators Association Regional Workshop in Chicago, IL. For additional

information on the workshop, see the IPFA ad on page 27/28.

|