|

TEMPLATE ROUTING WITH A VACUUM CLAMP

Vacuum can be used very effectively in the plastic fabrication shop. It's fast and grabs instantly; it provides up to 1800 pounds/sq.ft. of strong, tight holding force; it doesn't mar the work piece; there are no mechanical clamps to interfere with the routing process; you can go completely around the template in one pass, and it releases instantly.

Unless you are routing very small and thick pieces, a vacuum clamp will double or triple the output of template routing work when compared to using mechanical clamps or double sided tape. This can pay for the vacuum equipment in as little as one day of use.

Plastic is nonporous, smooth and flat; therefore, plastic fabrication shops have a significant advantage when using a vacuum clamp, no leakage. So the maximum holding force can be achieved. In addition, plastic scraps are available for making jigs, fixtures and templates, so the cost of material is minimal, especially when many templates have to be made.

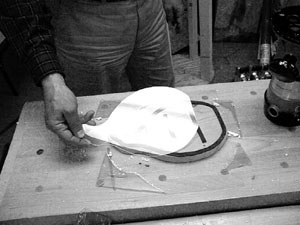

Making a vacuum template is quick and simple. We have used a template made from wood for better contrast. It's cut and sanded to shape and then a hole is drilled through the center. This allows vacuum to be applied to both sides. Next, the piece is outlined with a vacuum foam tape on both sides (top and bottom). The foam provides a seal between the template and the workpiece on top and the table on the bottom.

In this example we have a drilled hole in the solid tabletop with a vacuum line connected underneath. When we place the template over the hole, and put the workpiece on the template, it creates a vacuum cavity. Turning on the vacuum pump sucks all the air out from under the piece. The vacuum holds the template and piece to the table with about 400 pounds of force.

Calculating the holding force is straightforward. First you determine the area under the vacuum. In this case, about a 5" X 6" area or 30 sq.in. With the pump on, we reached 26 inches of mercury ("Hg); about the maximum. For every 2"Hg, we get 1 pound/sq.in. (psi) of holding force; a 2:1 ratio. Therefore, 26"Hg equals 13 psi. The 13-psi is multiplied by the 30 sq.in. of vacuum surface area. This equals 390 pounds of force holding the template to the tabletop and workpiece to the template.

One nice feature of the vacuum is that it holds with even and uniform pressure unlike a mechanical clamp, which holds with a point force.

And here is the completed piece. Because we were able to rout completely around in one pass (no mechanical clamps to interfere) we get a very accurate reproduction. When several router pieces are needed to fit together, vacuum template routing is the best option.

Other vacuum jigs that are useful are Straight Edges and Tee Squares. They can be placed anywhere on a sheet and the vacuum sucks them down exactly where they are placed. Another advantage of vacuum jigs is that they do not have to be at the edge of a sheet in order for the clamps to grip like with a mechanically clamped straight edge.

Those with pin routers will find vacuum templates significantly improve production. When routing large pieces, the vacuum template will be lighter since the weight of mechanical clamps is eliminated. One user required 2 men to shape 3' and 4' diameter tabletops because the template was too heavy for one man to handle safely. By switching to a vacuum template, one man is able to handle the job.

Prices for vacuum clamping systems vary from $100 to $1000. You have a choice between air-powered or electric pumps. The air-powered units are good for hand template routing since they are reliable and less expensive than the equivalent electric unit. Since plastic is nonporous, air-powered systems are generally more than adequate to meet most hand and pin routing needs. Our final photo shows manual and foot operated air-powered units, an electric vacuum pump, and vacuum tape and quick disconnects. All that is needed to make a template is a piece of plastic.

All units shown provide up to 1800 pounds/sq.ft. of clamping force. The manual unit (left) offers low cost while the foot operated unit (center) offers vacuum control with the pedal. This is about 20% faster for production work. It leaves your hands free to handle the router and workpiece. The electric pump with a foot pedal (right) offers the convenience of plugging in anywhere since no compressor is required.

Written by Ed Ferri, the founder of Quality VAKuum Products. Mr. Ferri has over ten years experience working with vacuum applications. Q.V.P. specializes in vacuum systems for the plastics and woodworking industries. They can be reached at 800-547-5485. Or see their web site: www.qualityvak.com.

|