|

See-Through Plastics Spotlight

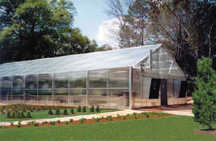

High Diffusion Panel

Polygal Inc. produces

Polymatte™ high diffusion

panel for the architectural

and commercial

greenhouse markets.

This unique panel

provides 99% diffused

light and 76% light

transmission and is

ideal for optimal plant

growth. Plants exposed

to direct light (no-diffusion)

produce a majority

of their food from the top leaves facing the sun. In the

greenhouse market the sheet will provide diffused light to

all leaves where all the leaves are able to photosynthesize

resulting in healthier, fuller plant development. In the

architectural market Polymatte can be used in place of

Opal where high light diffusion is beneficial.

Polygal produces a line of sheets that provide a broad

range of excellent solutions for uses such as skylights,

roofing and covering buildings, swimming pools and glazing

including the Stormguard Hurricane Protection

System and the Mega-Lock Aluminum Glazing System

specially designed for use in glazing 6 – 16 mm PC multiwall

sheets.

For additional information, contact Nick Koszegi,

Polygal, Inc., P.O. Box 410592, Charlotte, NC 28241,

800-527-0095, Fax: 704-588-7400, E-mail: sales@polygal.

com, Web: www.polygal-northamerica.com.

Museum Grade in .177

Thickness

Museum Grade in .177

Thickness

LuciteLux™

Museum

Grade UV

Max with

ultraviolet

protection

that filters

out 98 percent

of

harmful

ultraviolet

lighting is now available in a .177” thickness.

Museum Grade UV Max meets demanding museum standards,

is lightweight and allows for easy fabrication. The

product offers excellent optical quality and clarity and superior

craze resistance, is more impact resistant than glass,

and is easy to clean.

“Distributors and fabricators will now be able to provide

customers with a new measure of thickness and a new

choice in protecting and showcasing art, artifacts and

other displayed items,” says Sales Development Manager

Jane Nash.

Museum Grade UV Max also is available in a .118 thickness.

For additional information, contact Jane Nash, Lucite

International, 7275 Goodlet Farms Pkwy, Cordova, TN

38016, 800-4-LUCITE, E-mail: jane.nash@lucite.com,

Web: www.lucite.com.

PETG Sheet

PETG Sheet

SIMONA® SIMOLUX, the

transparent, break-proof

copolyester sheet made of

PETG, is a true all-around

material. Combining high

impact strength and excellent

thermoforming properties

with low flammability,

SIMOLUX is the perfect

material for a variety of

applications.

SIMONA® SIMOLUX is a

low flammability product in accordance with DIN 4102 B1; it is available in a transparent,

opal, satined or embossed design. SIMONA®

SIMOLUX-F offers a special low flammability (DIN 4102

B1 – non-burning droplets).

The materials are ideal for a variety of uses including

sales displays, illuminated signs exhibition design, ceiling

panels, machine covers, orthopedics, engineering and

design and more.

The sheet is extremely rugged, combining high impact

strength with excellent resistance to chemicals. It is crystal

clear for a sophisticated appearance and a brilliant surface.

The sheets are dyeable and can be used to create

special lighting effects – making it the perfect choice for

interior design applications. The sheet is particularly easy

to process and can be sawn, bolted, drilled, milled, laser

cut, glued, formed polished, die-cut and welded. The

sheets are suitable for deep-drawing and can generally be

processed without the need for pre-drying.

For additional information, contact John Ploskonka,

Simona America Inc., 64 N. Conahan Drive, Hazleton PA

18201, 866-501-2992, Fax: 800-522-4857, E-mail:

mail@simonaamerica.com, Web: www.simonaamerica.com.

Cell Cast Acrylic Sheet

Cell Cast Acrylic Sheet

Polycast

is the

world’s

largest

supplier

of specialty

cell

cast

acrylic

sheet,

manufactured

in the USA. They are an industry leading developer

and manufacturer of acrylic cell cast sheet for niche applications

in the military, aerospace, security glazing, medical

and other specialty markets. They have earned a reputation

for superior quality, reliability and customer service

and continue to successfully serve the market through

depth of stock and custom product.

Polycast can modify its acrylic sheet to change certain

physical, chemical or optical properties to help meet

your requirements, specifications or codes, including the

introduction of sensitive dyes and other additives. They

have an extensive color database and will cut sheet to

your size requirements, saving you time and money. They

can also achieve special tolerances for more critical

applications.

Sheet products include: Aerospace Military Specification

Grades, Bullet Resistant/Security Glazing, Special Light

Filtration (UF96 - UV Filtering, Solacryl UV transmitting)

and Special Performance Engineered sheet (Super

Abrasion Resistant, crystal clear extra thick sheet - thicker

than 4.500”), close tolerance (as thin as .020”), textured,

preshrunk and FDA compliant.

For additional information, contact Angelo Acocella,

Spartech Polycast, 70 Carlisle Place, Stamford, CT

06902, 800-243-9002/203-327-6010, Fax: 800-631-

4005, E-mail: angelo.acocella@spartech.com, Web:

www.polycast.com.

Expanded Architectural

Offerings

Reynolds Polymer

Technology, Inc. (RPT),

one of the world’s leading

acrylic manufacturers,

now caters not only

to distributers but directly

to the architectural

and interior design fields.

With six new acrylic

and resin-based products

joining their existing

acrylic sheet, rod and

tube line, RPT is poised

to deliver exceptional

products to an ever growing

and constantly

evolving field. Every

product is fully customizable

to suit the customers’ needs – whether it’s a unique

shape, a custom color or a custom image – and each product

can usually be delivered within weeks.

Whether it’s an ice-like texture as obtained through the

R-Cast™ Ice product, a subtle texture from the R-Cast™

Textures line, one of any of 120 transparent colors from

the R-Cast Palette line, a custom image as part of our RCast

Mirage product line, or a fire-resistant solid surface

material from their R-Cast Dura product, RPT can customize

each product to suit your needs. And, each product

benefits greatly from illumination that bring out the

subtleties of the material.

RPT continues to stock sheet up to four inches thick in

15’ lengths, as well as tube up to 96” OD and rod up to

12” OD. So whether you’re in the market for world-class

oversized sheet, rod or tube, or you’re looking for a product

for a custom interior design project, RPT can help.

For additional information, contact Julie Hober,

Reynolds Polymer Technology, Inc., 607 Hollingsworth

Street, Grand Junction, CO 81505, 970-241-4700, Fax:

970-257-1088, E-mail: juliehober@reynoldspolymer.com, Web: www.reynoldspolymer.com.

Acrylic

Components

For 100 years, Chelsea Plastics has

been the leader in the fabrication of

custom acrylic components.

Acrylic manufacturers and distributors

come to Chelsea Plastics for

machining

and

polishing

small

components,

particularly

those components that are too small

to be fabricated on their own machinery.

Their expertise in tumble polishing

ensures a superior finish on these

pieces. Their clients also look to them

for their hand polishing capabilities

when they need the best possible finish

on thicker and uniquely-shaped

components.

They specialize in fabricating acrylic

items that cannot be made elsewhere.

Nothing is too small or too difficult for

their design and fabrication experts. Is

your client's imagination running wild?

Feel like their creative department is

getting their ideas from outer space?

No problem - Chelsea can help.

For additional information, contact

Allen R. Frechter, Chelsea Plastics

Corporation, 30-02 48th Avenue,

Long Island City, NY 11101, 800-

524-2435/212-924-4530, Fax: 212-

924-3508, E-mail: info@chelseaplastics.

com, Web: www.chelseaplastics.com.

Next Generation

PC

Next Generation

PC

AmeriLux International’s Lexan

Thermoclear PLUS Twin Wall and

Triple Wall is now available in the

USA. This is a high performance polycarbonate

glazing material designed

27 years ago in Europe specifically for

the building material industry where

high light transmission and excellent

insulation is a requirement. The panels

offer natural lighting, high UV protection

performance, superior energy

efficiency, easy fabrication and light in

weight yet virtually unbreakable.

Their panel is one of the best performing

polycarbonate multiwall glazing

materials in the industry and has

virtually no yellowing. Their sheets

come in thicknesses from 4mm up to

50mm with sheet lengths up to 48

foot long. With their latest state–of-the-art technology, they can offer a

self-cleaning hydrophobic coating

that creates larger droplets to form

and wash away dirt that leaves the

sheet spotless. Coming in early 2011,

they will be introducing their complete

line of Lexan Polycarbonate

Standing Seam Sheet Systems.

For additional information, contact

Tami Churchill, AmeriLux

International, 1212 Enterprise Drive,

DePere, WI 54115, 888-602-4441,

Fax: 920-336-9301, E-mail: ameriluxtami@aol.com, Web: www.ameriluxinternational.com.

Reinforced

Acrylic Sheets

Reinforced

Acrylic Sheets

American

Acrylic

Corporation

manufactures

LUMAsite®

reinforced

acrylic

sheets and

lighting diffusers.

These elegant

translucent

panels are used extensively in architectural, display and fixture lighting, partitions, illuminated

walls, canopies, oriental décor, window treatments

and much more.

The combination of translucent beauty and long-term

durability (indoors or out) makes LUMAsite® sheets an

outstanding choice for all kinds of light-diffusing applications.

Varieties include graceful rice-paper and frosted

effects, several translucent (and opaque) white varieties,

delicate tints and fabric embedments.

All standard varieties and thickness are available in a

choice of sheet sizes up to 4’ x 10’. Some varieties available

in larger sheet sizes. Panels can also be cut to the

exact size needed.

For additional information, contact Maryann West,

American Acrylic Corporation, 400 Sheffield Ave. West

Babylon, NY 11704, 800-627-9025/631-422-2200, Fax:

631-422-2811, Web: www.americanacrylic.com.

Clear “Armor”

Clear “Armor”

While digital technology

expands design possibilities

for indoor and outdoor

signage and visual

displays, it also creates a

critical need to protect

electronics from severe

weather and vandalism.

Display Devices, Inc. of

Arvada, Colorado, recently

brought this design

challenge to Sheffield

Plastics, a Bayer

MaterialScience LLC

Business and leading producer

of Makrolon® polycarbonate

sheet products.

The digital display manufacturer designs and builds

standard and custom display products for a customer base

that includes hotels, airports and corporate facilities

around the world. Units typically must reflect a client company’s

image and complement its facilities’ architecture.

The clear display panels for outdoor installations in particular

must withstand the rigors of rain, high wind, hail,

extreme temperature and sun exposure and are subject to

damage from vandalism.

According to Jeremiah Hueske, Industrial Designer for

Display Devices, performance and integrity of the display

screen was also a key factor in their ability to promote

their product reliability and its warranty. “We evaluated

several traditional clear materials for break-resistance and

the ability to maintain clarity long term. We also wanted

to comply with UL flammability ratings. Glass, acrylic and

standard polycarbonate all fell short on one or more of the

key performance criteria.” After consulting with Sheffield

Plastics, the designer opted for a grade of Makrolon polycarbonate

sheet that offers exceptional abrasion resistance,

optical clarity and a warranty against breakage.

For additional information, contact Cindy Kahlstrom,

Sheffield Plastics Inc., 119 Salisbury Road, Sheffield, MA

01257, 800-254-1707, Fax: 800-457-3553, E-mail:

cindy.kahlstrom@bayerbms.com, Web: www.sheffieldplastics.

com.

Fabrication Supplies &

Accessories

For many years FTM, Inc. has been your "Fabricators

Source" for all of your plastic fabrication needs. FTM carries

a wide variety of products specifically designed for the

plastics industry including strip heaters for bending plastics,

tooling and a

large selection of hardware.

If you’re looking

for tooling such as

router bits, drill bits or

saw blades, and hardware

such as hinges,

hasps, turntables or

locks, then this is the

place. To complete

your jobs, they even

stock solvents, applicators,

cleaners and polishes.

To their ever-expanding

line, they

are proud to announce

the addition of Outdoor Real Estate Boxes. These durable

boxes are weatherproof, self-closing and made from non-yellowing

heavy duty plastic. They are easily mounted anywhere

with the "E-Z peel & stick mounting system." Each

real estate box will hold approx. 150 flyers. There are several

sizes to choose from including, standard, tri-fold and

business card. They also carry a complete line of high

quality indoor literature and business card holders.

Request a catalog today for complete information on all of

their products.

For additional information, contact David Geer, FTM,

Inc., 327 Industrial Dr. Unit 1, Placerville, CA 95667,

530-626-1986, Fax: 530-642-2602, E-mail:

info@123ftm.com, Web: www.123ftm.com.

Multiwall & Corrugated PC

CO-EX Corporation is a leader in the development of multiwall

and corrugated polycarbonate sheet materials.

Innovation drives the core of the company with new sheet

products, new panel and system products and new solid

sheet products constantly being introduced into various market segments including: Architectural - applications such as roofing,

skylights, walkways, canopies, fa -

cades and other glazing panels.

Horticultural - applications for the

green house and growers market.

General plastic applications such as;

partitions, graphic and decorative

displays.

New to CO-EX is solid polycarbonate

sheet, Macrolux C from 0.093”

thick through 0.500” thick.

All the multiwall products save energy

in two ways: 1) they let in natural

light thus reducing electricity usage

and 2) all products provide very high

insulation properties which reduces

energy usage and CO2 emissions.

CO-EX Corporation has been serving

the North American market since

1988. Their multiwall products begin

at 4 mm thick and go up to 60 mm

thick, so a wide range of products are

available to meet your needs.

For additional information, contact

Janice Pravorne, CO-EX Corporation,

5 Alexander Drive, Wallingford, CT

06492, 800-888-5364, Fax: 203-

679-0600, E-mail: info@co-excorp.com. Web: www.co-excorp.com.

Eye-Grabbing

Displays

Evonik Cyro’s ACRYLITE® sheet, rod

and tube offerings are perfect for creating

exciting and visually appealing

displays and tradeshow booths. For

designers and fabricators looking to

achieve any number of effects, there

are numerous ACRYLITE products

that can help them to draw attention

to an exhibit.

A few of Evonik Cyro’s offerings

include ACRYLITE Radiant sheet,

Fluorescent ACRYLITE GP sheet or

Exotic Edge ACRYLITE GP sheet. Each

provides a frosted finish with high

light transmission and even light diffusion

to hide hot spots caused by LED

lights or other light sources. Another

benefit is that the ACRYLITE products

resist fingerprints due to their finish.

Other products from Evonik Cyro,

such as ACRYLITE Trend Textured sheet

or Stippled Texture, allow exhibitors to

create interest or privacy by using textures

and patterns, while maintaining

the appearance of glass without the

risk of breaking. Additionally, a mirror

finish can be created with lower costs

than competing products.

By combining any of Evonik Cyro’s

ACRYLITE products with lighting,

tradeshow designers and exhibitors

can create eye-grabbing booth displays

that draw attention from show

attendees with color shifting lighting

effects or allow the edges to glow.

For additional information, contact

Gail Wood, Evonik Cyro LLC, 379

Interpace Parkway, Parsippany, NJ

07054, 800-631-5384/973-541-

8754, Fax: 973-541-8445, Email:

gail.wood@evonik.com, Web: www.

acrylite.net.

|