|

PE & PP Spotlight

Polyethylene (PE) and Polypropylene (PP) are two of the

largest volume thermoplastics used today and are available

in a wide range of grades and formulations - commonly

grouped into Low, Medium and High density. The

various formulations of these popular polyolefins impart a

wide range of properties making them appropriate for

countless applications. Generally speaking, polyolefins are

tough, chemical resistant and offer good electrical properties

with a low coefficient of friction and moisture absorption.

They are relatively light weight and easy to fabricate.

Polyolefins find proven applications in a wide range of

markets from medical and chemical to toys and sporting

goods and oil and gas to food processing and marine.

Following is an overview of a variety of materials from

sheet, rod and tube to massive shapes and profiles.

Close Tolerance Rod

Artek offers rod dowelling services to provide close tolerance

Duravar® rod stock with excellent concentricity

to meet the needs of today’s critical machine and job

shop operations.

Artek offers rod dowelling services to provide close tolerance

Duravar® rod stock with excellent concentricity

to meet the needs of today’s critical machine and job

shop operations.

Artek is a leading supplier of UHMW rod stock to the

plastic distribution market place. Their full line of extruded

UHMW-PE rod is offered in

diameters from 1/4" up

through 10" in virgin, reprocessed

and enhanced formulations.

Artek provides a large

range of standard diameters,

dowelled to close tolerance,

ranging from 1" up through

3" diameter. In addition they

will quote custom dowelled

diameters upon request.

Their dowelling system provides excellent diameter concentricity

with tolerances as close as +/- .003" to help

improve secondary machining processes.

The rod is available in a variety of standard and custom

colors that meet FDA and USDA requirements. Artek can

also color match to meet the needs of the project.

In addition to the traditional 5' and l0' industry standard

lengths, Artek can provide up to 20' lengths.

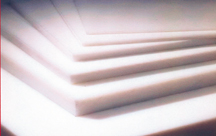

Full Sheet Stock

Artek also introduced the newest member of the Duravar UHMW-PE family of extruded and skived full sheet as a

standard product line. Artek’s in-line stress relieving

process reduces stress, improves productivity and minimizes

waste when cutting this prime material into blocks or

strips. The sheet

has excellent

surface finish

and thickness

consistency.

Sheet sizes are

48” x 96” and

48” x 120” in

thickness from

1/8” up to 2”.

For additional information, contact Randall Kirkpatrick,

Artek, Inc., 3311 Enterprise Road, Fort Wayne, IN

46808, 800-762-6808, Fax: 260-484-6914, Web:

www.artek-inc.com.

UHMW High Bond Tape

UHMW High Bond (HB) Tape has all the benefits of

strong, slippery, abrasion-resistant UHMW (ultra-high

molecular weight) polyethylene tape, plus a super-high

bond adhesive. UHMW High Bond is an excellent choice

for difficult-to-bond, low surface energy surfaces such as

powder-coated, plastic,

foam, oily metals,

slightly textured.

UHMW-HB (#19-HB

Series) even sticks to

high slip surfaces:

Teflon®, Acrylic, PE

and more.

UHMW High Bond (HB) Tape has all the benefits of

strong, slippery, abrasion-resistant UHMW (ultra-high

molecular weight) polyethylene tape, plus a super-high

bond adhesive. UHMW High Bond is an excellent choice

for difficult-to-bond, low surface energy surfaces such as

powder-coated, plastic,

foam, oily metals,

slightly textured.

UHMW-HB (#19-HB

Series) even sticks to

high slip surfaces:

Teflon®, Acrylic, PE

and more.

The tape is available

in many film

thicknesses: .010",

.020", .030", .060",

.090" and .125".

Adhesive is .002"

thick. Black Semi-

Conductive, Anti-

Static UHMW High

Bond Tape is also

available. Standard

Widths are .5", .75", 1", 2", 6", 12". Rolls are 5 yards

long. Custom widths, thicknesses and lengths are also

available. CS Hyde Company can custom die-cut UHMW

HB into labels, discs, squares, etc.

For additional information, contact Tiffany Dost, CSHyde Company, 1351 N. Milwaukee Ave., Lake Villa, IL

60046, 800-461-4161, Fax 800-441-8063, E-mail:

sales@cshyde.com, Web: www.cshyde.com.

35 Years of Firsts

In the mid-1970s Crown Plastics, Inc . perfected the art of

compression molding thin-gauge UHMW-PE into continuous

coils. The tough, lightweight plastic was flexible,

smooth and easily machined.

compression molding thin-gauge UHMW-PE into continuous

coils. The tough, lightweight plastic was flexible,

smooth and easily machined.

A few years later Crown’s R&D people discovered how to

make UHMW coils bondable. Adhesive-backed

UHMW-PE tape was an industry first.

In 1992 Crown Plastics introduced a new sintered

base into the snowboard materials market. Called

DuraSurf™, it rapidly set the standard for high-performance

and

drew international

attention in 2006

when 4 of the 6

medalists in the

Men’s and

Women’s Halfpipe

Competition rode boards made with DuraSurf base.

In 2007 Crown Plastics introduced Dura-Slick™, a

bondable UHMW product made especially for the

drift boat industry in the Pacific Northwest. At

.093” thick, black Dura-Slick is UV stable, lighter

than UHMW sheet and less expensive than other

hull treatments.

For additional information, contact Crown

Plastics, Inc., 116 May Dr., Harrison, OH 45030,

800-328-0238, Fax: 513-367-4004, E-mail: info@

crownplastics.com, Web: www.crownplastics.com and

www.durasurf.com.

Custom Profile

Extrusion

Garland Manufacturing

Garland Manufacturing specializes in custom

profile extrusion of GAR-DUR® UHMW Polyethylene.

Garland

manufactures extruded

board stock to

24” wide of unlimited

length, rod to 8”, with

special-order availability

of 12” hollowcore

stock, and bars

and tubes of various

standard dimensions.

GAR-DUR UHMW is

produced in virgingrade

per ASTM

D-4020-05a with a minimum molecular weight of 4.2

million; filled and additive varieties are available by special

request.

Garland can also handle your specialized applications,

including conveyor, transportation, wastewater treatment,

agricultural machinery and any other high-impact or highabrasion

use.

For additional information, contact Dan Garland,

Garland Manufacturing Co., P.O. Box 538, Seco, ME

04072, 207-283-3693, E-mail: dgarland@garlandmfg.com., Web: www.garlandmfg.com.

30% GF Polypropylene

GEHR Plastics offers GEHR Polypropylene, which

demonstrates a high mechanical and tensile strength

and is coupled with great impact strength. GEHR

Polypropylene resists stress cracking and is easy to weld.

Chemical and electrical

properties are

excellent and operating

temperatures

range between 41°F

to 210°F. Characteristics

include low

density, low moisture

absorption, good

heat resistance, high

chemical resistance,

high tensile strength,

high surface strength but low abrasion resistance. Natural

is copolymer resin and colored is homopolymer.

Polypropylene resists stress cracking and is easy to weld.

Chemical and electrical

properties are

excellent and operating

temperatures

range between 41°F

to 210°F. Characteristics

include low

density, low moisture

absorption, good

heat resistance, high

chemical resistance,

high tensile strength,

high surface strength but low abrasion resistance. Natural

is copolymer resin and colored is homopolymer.

GEHR also offers GEHR HiPro® 30% glass reinforced

polypropylene. This material maintains the excellent

chemical and corrosion resistance of unfilled PP with

added superior dimensional stability (CLTE = 3.0 x 10√5

in/in/°F), higher surface stiffness, higher temperature

resistance with a Heat Deflection Temperature of +319°F

and much better compressive strength.

The color is black and is targeted for higher temperature

chemical applications where cost is an issue.

For additional information, contact Bill Shields, GEHR

Plastics USA, 24 Creek Circle, Boothwyn, PA 19061, 800-

PVC-GEHR/610-497-8941, Fax: 610-497-8901, E-mail:

info@gehrplastics.com, Web: www.gehrplastics.com.

Sheets, Slabs & Massive

Shapes

Now celebrating its 40th anniversary, King Plastic

Corporation, is a leading innovator and manufacturer

of high-quality polymer sheets, slabs and massive

shapes. While the company is well known for its King

StarBoard® family of marine polymers, there is much more

to King. Its polymer products include an extensive list of

commodity polymers: UHMW/VHMW, HDPE/LDPE, cutting

board, borated PE, pipe grade and polypropylene, as

well as colorful signage/playground PE, sturdy restroom

partition sheets, and engineering materials such as ABS.

shapes. While the company is well known for its King

StarBoard® family of marine polymers, there is much more

to King. Its polymer products include an extensive list of

commodity polymers: UHMW/VHMW, HDPE/LDPE, cutting

board, borated PE, pipe grade and polypropylene, as

well as colorful signage/playground PE, sturdy restroom

partition sheets, and engineering materials such as ABS.

The King heritage is a tireless commitment to innovation,

quality and service. Their comprehensive line of

branded

and commodity

products

are manufactured

at a stateof-

the-art

150,000

sq. ft. factory

in

North

Port,

Florida, and distributed worldwide. Best of all their knowledgeable

and experienced staff provide answers, not just

prices to distributors.

King Plastic Corporation offers 29 products in sheets,

slabs and massive shapes, is and is

capable of manufacturing sheets to

more than 120’ x 8’, slabs to more

than 30” thick and massive shapes

to more than 5,000 lbs.

For additional information, contact

Lou Stegner, King Plastic

Corporation, 1100 N. Toledo Blade

Blvd., North Port, FL 43288, 941-493-5502, Fax: 941-497-3274, Email:

lou@kingplastic.com, Web:

www.kingplastic.com.

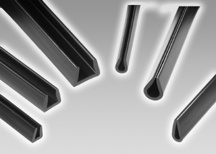

PE Channels

Petro Extrusion Technologies

Inc., (PET Inc.) specializes in

engineering grade thermoplastics

as well as custom and stock products

in low, linear low, medium and

high density polyethylene. PET, Inc.

carries a stock line of 6 different PE channel shapes. The stock channels can also be made-to order

in any desired cut lengths.

in low, linear low, medium and

high density polyethylene. PET, Inc.

carries a stock line of 6 different PE channel shapes. The stock channels can also be made-to order

in any desired cut lengths.

PET Inc., also produces an endless variety of custom

shapes and tube sizes ranging from 1/32” diameter up to

6” diameter.

Petro has custom

co-extrusion

capability and

can extrude in

any combination

of compatible PE

materials or colors

as your

requirement dictates.

They specialize in neon and specialty custom colors,

as well as all standard colors.

For additional information, contact Robert Petrozziello,

Petro Extrusion Technologies, Inc., P. O. Box 99, 490

South Ave., Garwood, NJ 07027, 800-229-3338/908-789-3338, Fax: 908-789-0434, E-mail: rpetro@petroextrusion.com, Web: www.petroextrusion.com.

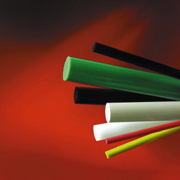

PP Stock Shapes

Plastifab Industries offers a comprehensive product line

of standard stock shapes in Low Density, High Density

and Polypropylene commonly known as polyolefins.

Polyolefins finds proven applications in markets such as

medical, chemical, toys, sporting goods, oil and gas and

food processing. LDPE, HDPE and polypropylene rods are

available in

sizes ranging

from 1/8” to

16” diameter

in natural

and black.

Polyolefin

heavy wall

tubular bar is

offered with

a minimum

ID of 2”

through and OD of 22”.

medical, chemical, toys, sporting goods, oil and gas and

food processing. LDPE, HDPE and polypropylene rods are

available in

sizes ranging

from 1/8” to

16” diameter

in natural

and black.

Polyolefin

heavy wall

tubular bar is

offered with

a minimum

ID of 2”

through and OD of 22”.

Semi-rigid polyolefin tubing is a mainstay in oil,

hydraulic fluid, water and beverage transfer, oil and gas

and is available in Diameters as small as .170" inside in

natural and a wide selection of colors.

Welding rods are available in LDPE, HDPE and

polypropylene and are used in conjunction with sheet and

plate to fabricate tanks, tank liners and boxes for corrosive

environments.

Polyolefin standard stock shapes are typically manufactured

from FDA-approved resins and meet USDA, NSF

and Canadian Department of Agricultural requirements

for direct food contact.

For additional information, contact Plastifab Industries,

7777 Transcanadienne, Saint Laurent, Quebec, H4S 1L3,

Canada, 800-361-4774/514-325-9840, Fax: 514-325-

522, E-mail: infoprod@plastifab.ca, Web: www.plastifab.ca.

PP Sheet

Polygal

Polygal announced the addition of a unique, new and

improved 8mm polypropylene sheet for the building

materials and commercial greenhouse markets. The sheet,

designed for

use as side

and end

walls in the

greenhouse

market, can

also be specified

and

installed for

interior

applications

in

the architectural market where privacy and/or

back lighting is desired. The new 8mm polypropylene

sheet by Polygal is UV protected through the

entire sheet, not just co-extruded on one or two

surfaces.

For additional information, contact Ward Ogle,

Polygal, Inc., P. O. Box 410592, Charlotte, NC

28241, 800-527-0095, Fax: 704-588-7400,

E-mail sales@polygal.com, Web: www.polygal.com.

Medical Grade PP

Westlake Plastics Company

Westlake Plastics Company offers Medical

grade Propylux HS. Medical grade Propylux

HS is made from an FDA approved polypropylene

resin. Through a unique heat-stabilizing process,

the extruded material is able to withstand higher

temperatures with less water absorption than

standard polypropylene. Recommended sterilization

techniques for Propylux HS include steam

autoclaving and cold sterilization.

Applications include provisional trials and

instrument handles. The material offers excellent

chemical resistance, is laser markable, lot controlled

and traceable, has low moisture absorption,

is FDA resin - USP Class VI and has superior

dimensional stability.

For additional information, contact Gary King,

Westlake Plastics Company, P.O. Box 127, Lenni,

PA 19052, 800-999-1700/610-459-1000, Fax:

610-459-1084, E-mail: gary@westlakeplastics.com, Web: www.westlakeplastics.com.

|