|

IWF Preview

The International Woodworking Machinery &

Furniture Supply Fair-USA® will feature nearly 1,400

exhibitors August 23-26, 2006 at the Atlanta Convention

Center, Atlanta, Georgia. At IWF 2006 there will be the

opportunity to view technology that will decrease production

costs, while improving profits, creating new opportunities

for economic growth while sustaining a global competitive

edge in the global marketplace.

The following companies will be showing machinery and

tooling designed specifically for the plastics industry. For

more information on IWF 2006, visit www.iwf2006.com.

Benders & Polishing

Machines

A.W.E.D. Corp. offers one of the most comprehensive

lines of benders available in the U.S. today. Benders

feature either wire or quartz elements housed in a patented

system that will adjust the aperture of heat exposure

to the sheet for the ultimate in bending of sharp or long

90° bends in thin or thicker material. See a preview of

the different sizes and types they offer at IWF 2006.

They also offer edge polishers, straight or bevel, in a

large selection of models and sizes.

In addition, A.W.E.D. carries plastic cutting saw blades

featuring a triple-chip grind (TCG) tooth design from 10”

to 16” diameter and panel sizing equipment.

For additional information, contact Victor Miranda,

A.W.E.D. Corp., 1175 Buford Hwy., Suite 101, Suwanee,

GA 30024, 770-831-9800, Fax: 770-831-7404, E-mail:

victor@awedmachine.com, Web: www.awed-machine.com.

IWF Booth #8262

CNC Band Saw

The Byrnes/Veneta Model “Mars” CNC-controlled band

saw streamlines the process of cutting blank pieces.

Operators no longer need

to trace an outline of a

blank piece, and the precise

movement of the machines

cuts parts accurately.

blank piece, and the precise

movement of the machines

cuts parts accurately.

Richard T. Byrnes Co.

offers machinery for chairs

and furniture, including CNC machining

centers; mortisers; tennoners; shaping/sanding machines and 5-axis CNC bandsaws.

For additional information, contact Larry Tolbert,

Richard T. Byrnes Co., 600 Hannum Avenue, West

Chester, PA 19380, 610-692-2770, Fax: 610-692-3318,

E-mail: byrnes@rtbyrnes.com, Web: www.rtbyrnes.com.

IWF Booth #8752

CNC Routers

CNT Motion’s hottest-selling

machine is

the full-size, servopowered

CNT-1000.

It’s built to tackle

heavier applications

including plastics, solid

surface, non-ferrous metals

and hardwoods affordably

and at up to 2,000 ipm. CNT’s

heavy-duty routers are being used for nested-based manufacturing

and are compatible with major nesting software

packages. Optional features include tool changers,

boring heads and vacuum fixturing.

heavier applications

including plastics, solid

surface, non-ferrous metals

and hardwoods affordably

and at up to 2,000 ipm. CNT’s

heavy-duty routers are being used for nested-based manufacturing

and are compatible with major nesting software

packages. Optional features include tool changers,

boring heads and vacuum fixturing.

For additional information, contact Max Andrzejewski,

CNT Motion Systems, 7800 Susquehanna Street,

Pittsburgh, PA 15208, 412-244-5770, Fax: 412-244-

5760, E-mail: maxa@cntmotion.com, Web: www.cntmotion.

com.

IWF Booth #9852

New 3-Axis

CNC Router

This heavy duty 3-axis CNC router features all tube

construction and is equipped with dual 5 x 8 foot

tables with dual automatic tool changers on individual

tool plates.

Each 11 hp HSK 63 spindle is serviced by its

own servo controlled 8 station traveling carousel

toolchanger. The spindles have adjustable spacing across

the bridge to accommodate various part sizes. Each aluminum

table has a machined multi-zone vacuum plenum

that can be controlled manually or

automatically. The DMS MT

85T is equipped with

the Fagor 8055 controller.

A TCP/IP network

connection, 1 Gb

compact flash memory

card and remote telediagnostics

are available

on the Fagor 8055. All

axes are driven by state-of-the-art brushless AC servo

motors and fixed screw spinning ballnuts on the X and Y

axes for increased speed and rigidity. An automatic lubrication system is plumbed to all way bearings and ballnuts,

insuring long term durability and reduced maintenance

downtime.

Each 11 hp HSK 63 spindle is serviced by its

own servo controlled 8 station traveling carousel

toolchanger. The spindles have adjustable spacing across

the bridge to accommodate various part sizes. Each aluminum

table has a machined multi-zone vacuum plenum

that can be controlled manually or

automatically. The DMS MT

85T is equipped with

the Fagor 8055 controller.

A TCP/IP network

connection, 1 Gb

compact flash memory

card and remote telediagnostics

are available

on the Fagor 8055. All

axes are driven by state-of-the-art brushless AC servo

motors and fixed screw spinning ballnuts on the X and Y

axes for increased speed and rigidity. An automatic lubrication system is plumbed to all way bearings and ballnuts,

insuring long term durability and reduced maintenance

downtime.

For additional information, contact Denny Brazelton,

Premier Tech Products, Inc. at 330-923-3125 or Jeff Stein,

Creative Machine Technology, Inc. at 330-923-2154,

E-mail: dennybrazelton@sbcglobal.net or creativemachine

@sbcglobal.net, Web: www.5axiscncrouter.com.

IWF

Booth #7081, also see them at SPE Booth #431

Routers and Saws for

Plastics

Delmac Machinery Group (DMG) provides the machinery

and service needed to increase production. They

represent Busellato (CNC machining centers, CNC

Routers, Feed Through machines), Delmac Engineering,

Celaschi and Gabbiani

(Single & Double

End Tennoners,

Combination

Machines),

SAG (Material

Handling), Mayer

(Panel Saws), OMAL

(Bore, Glue, Dowel & Hardware Insertion Machines) and

Fravol (Straight and Contour Edgebanders). These

machines will be available at IWF for demonstration; let

their knowledge go to work for you.

The PS2 Z120 offers a high output with its 4.7” blade

projection, optional 7.8” cutting height and fast traverse

speeds while maintaining the dimensional accuracy and

superior cut quality required by the most discriminating

customers.

(Single & Double

End Tennoners,

Combination

Machines),

SAG (Material

Handling), Mayer

(Panel Saws), OMAL

(Bore, Glue, Dowel & Hardware Insertion Machines) and

Fravol (Straight and Contour Edgebanders). These

machines will be available at IWF for demonstration; let

their knowledge go to work for you.

The PS2 Z120 offers a high output with its 4.7” blade

projection, optional 7.8” cutting height and fast traverse

speeds while maintaining the dimensional accuracy and

superior cut quality required by the most discriminating

customers.

For additional information, contact Gerri Bolton,

Delmac Machinery Group, 4322 Piedmont Parkway,

Greensboro, NC 27410, 336-854-1211, Fax: 336-854-

0811, Web: www.delmac.com.

IWF Booth #8806

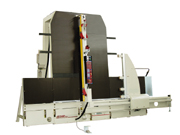

Saws and Routers

Hendrick Mfg. Corp. will

be showing their line

of saws and routers for

plastics at IWF booth

#8640. They manufacture

a complete line of

fully automated computerized

vertical

panel saws.

The

machine controller has

large program storage capacity and can receive off line cut

optimization patterns via RS232C interface. Cut lengths

range from 4’ through 10’ models. Solid phenolic table

surfaces and a full length pneumatic hold down bar

together with 7.5 hp blade motor allow stack cutting and

cutting of thin strips. Precision material indexing is by

THK ball screw and linear ways. The material pusher can

operate in either absolute or incremental mode.

The

machine controller has

large program storage capacity and can receive off line cut

optimization patterns via RS232C interface. Cut lengths

range from 4’ through 10’ models. Solid phenolic table

surfaces and a full length pneumatic hold down bar

together with 7.5 hp blade motor allow stack cutting and

cutting of thin strips. Precision material indexing is by

THK ball screw and linear ways. The material pusher can

operate in either absolute or incremental mode.

Hendrick will also feature their

line of economically

priced fully automated

computerized

horizontal panels

saws configured

specifically for the

plastic industry. Solid

phenolic rear table surfaces

support thin sheets, small strips, rod and tubing.

Full length pusher plates or combination pusher plate

with material grippers are available. Adjustable saw kerf

strips and full length pneumatic hold down bar support

material for chip free cutting. Variable speed saw carriage

traverse by AC inverter with high speed return and high

speed AC servo material indexing are standard features.

The material pusher can operate in either absolute or

incremental mode. The machine controller has large program

storage capacity and can receive off line cut optimization

patterns.

CNC Router

They will also show

their 20ZXG CNC router

which offers high

speed and accurate

machining capabilities.

Feed rates up

to 2,500 i.p.m. and positioning

accuracy of +/- 0.002” with repetitive

accuracy of +/- 0.008” can be obtained.

The moving gantry design utilizes AC servo drives, linear

ways and ball screws on all axes for smooth and accurate

movement. Up to 15 hp, high frequency router spindles

with automatic tool changing capability are available.

Other features include a PC controller with built in

CAD/CAM software, a vacuum table machined for zoning

and pod fixturing, a low vacuum pressure safety cut off

and air blast tool cooling. The machine is available in

many different table sizes.

machining capabilities.

Feed rates up

to 2,500 i.p.m. and positioning

accuracy of +/- 0.002” with repetitive

accuracy of +/- 0.008” can be obtained.

The moving gantry design utilizes AC servo drives, linear

ways and ball screws on all axes for smooth and accurate

movement. Up to 15 hp, high frequency router spindles

with automatic tool changing capability are available.

Other features include a PC controller with built in

CAD/CAM software, a vacuum table machined for zoning

and pod fixturing, a low vacuum pressure safety cut off

and air blast tool cooling. The machine is available in

many different table sizes.

Hendrick announced the redesign of their website to

better serve their customers and will have new product literature

available at the IWF show.

For additional information, contact Richard Cohen,

Hendrick Mfg. Corp., 32 Commercial Street, Salem, MA

01970, 978-741-3600, Fax: 978-744-0242, E-mail:

info@hendrickmfg.net, Web: www.hendrickmfg.net.

IWF Booth #8640

Economical CNC Router

Omnitech Systems Inc.

will feature its latest

addition to the SELEXX

family of CNC Routers,

the ECO. The router features

a 10 hp spindle,

8 position automatic

tool changer with HSK

63F tool holders, a piggyback

drill, Fanuc controller, industrial vacuum

pump and much more.

family of CNC Routers,

the ECO. The router features

a 10 hp spindle,

8 position automatic

tool changer with HSK

63F tool holders, a piggyback

drill, Fanuc controller, industrial vacuum

pump and much more.

Offered with a 4’ x 8’ table, the machine base is constructed

of heavy duty industrial grade welded steel with

multiple reinforcements throughout to provide added stability.

The heavy duty gantry construction, supported on

both sides of the table, ensures vibration free and precision

processing of a variety of materials.

The SELEXX/ECO offers industrial features at a truly

affordable price of $59,900.

For additional information, contact Raymond Ward,

Omnitech Systems Inc., 8100-A Arrowridge Blvd.,

Charlotte, NC 28273, 704-529-8369, Fax: 704-529-

8374, E-mail: sales@omnitech-systems.com, Web:

www.omnitech-systems.com.

IWF Booth #6048

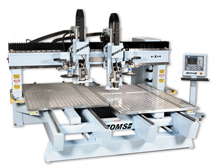

Multi-Head Dual Process

Technology

With the

Optional

C.R. Onsrud

Multi-Head Dual

Process Technology,

you can get the

throughput of two

complete machines

out of a single machine footprint. Start with any Standard 3-,

4- or 5-axis C.R. Onsrud Extreme Duty Series twin table

model, and then add a second tool changer and a second

main router spindle. When teamed up with the dual process

power and capabilities standard in their OSAI controller, you

get their Multi-Head Dual Process Technology. Even additional

drilling or boring blocks, aggregate tool changers or

multiple c-axis can be added as options.

out of a single machine footprint. Start with any Standard 3-,

4- or 5-axis C.R. Onsrud Extreme Duty Series twin table

model, and then add a second tool changer and a second

main router spindle. When teamed up with the dual process

power and capabilities standard in their OSAI controller, you

get their Multi-Head Dual Process Technology. Even additional

drilling or boring blocks, aggregate tool changers or

multiple c-axis can be added as options.

For additional information, contact C.R. Onsrud Inc.,

P.O. Box 419, Troutman, NC 28166, 800-638-8185/704-528-4528, Fax: 704-528-6170, Web: ww.cronsrud.com.

IWF Booth #8106

Tooling for Plastics

Advantage, a favorable

factor or circumstance,

a benefit or profit.

The key

word in this definition is

profit. In the world of CNC

routing, proper usage of

tooling is the key to productivity

and profitability. If your company is looking for the

edge to increase bottom line profits, “theONSRUD advantage”

may be for you.

The key

word in this definition is

profit. In the world of CNC

routing, proper usage of

tooling is the key to productivity

and profitability. If your company is looking for the

edge to increase bottom line profits, “theONSRUD advantage”

may be for you.

During IWF 2006, Onsrud Cutter LP and their team of

application specialists will be demonstrating the advantage

of proper tool selection and application by running

live parts in the booth with a state-of-the-art CNC router.

The materials will include wood, plastic and aluminum,

which represent real world applications encountered by

the typical CNC shop everyday.

If you want to be more profitable, take some time to

visit Onsrud Cutter LP in Building C, Booth 8126 find out

about the real advantage.

For additional information, contact Marybeth Thomas,

Onsrud Cutter LP, 800 Liberty Drive, Libertyville, IL 60048,

847-362-1560, Fax: 847-362-5028, Web: www.onsrud

.com or www.plasticrouting.com.

IWF Booth #8126, also

see them at SPE Booth #306

Saws and Routers

SCM Group will feature several

saws and routers

designed specifically

for plastic distributors

and fabricators at IWF.

The PLM panel saws provide

superior cutting quality while

reducing material waste and improving yield

at an affordable price. The Galaxy 125 PLM (4.5” cutting

capacity) and Sigma 105 PLM (3.5” cutting capacity) will

be available for demonstration at booth #8340 and

8326.

The PLM panel saws provide

superior cutting quality while

reducing material waste and improving yield

at an affordable price. The Galaxy 125 PLM (4.5” cutting

capacity) and Sigma 105 PLM (3.5” cutting capacity) will

be available for demonstration at booth #8340 and

8326.

There are four models designed to meet the plastic

industries’ cutting requirements. Value added features

include high speed carriage movement with optimized

operation for fast cycle times; a worktable designed to cut

thin materials; RPM control on independent main motor

for best edge results; main blade cooling; 48” wide rear

phenolic crosscut table for effectively cutting thin strips

and small parts and a pusher with clamps for quick, accurate

loading and cutting.

Equipped with with Cutty Sheet Optimization Software.

The PLM also includes a modem connection available for

on-line technical support and many other advanced technology

capabilities. The PLM is available in 10.5’, 12.5’ or

14.5’ cutting lengths.

CNC Routers for Plastics

SCM Group will introduce the Pratix BDG 5

CNC Router for machining all types of plastic

materials. The Pratix brings flexible

CNC machining

capability to an entrylevel

machine without

making compromises.

The Pratix features a 5’ x 12’

work area, powerful 9/10hp HSK F63 router motor and an

eight-position rapid on board tool changer. The flexible

aluminum grid vacuum table provides effective hold down

for small parts. The Pratix has a user-friendly interface

and is supplied with CAD/CAM software compatible with

all major design software packages.

CNC machining

capability to an entrylevel

machine without

making compromises.

The Pratix features a 5’ x 12’

work area, powerful 9/10hp HSK F63 router motor and an

eight-position rapid on board tool changer. The flexible

aluminum grid vacuum table provides effective hold down

for small parts. The Pratix has a user-friendly interface

and is supplied with CAD/CAM software compatible with

all major design software packages.

SCM Group also offers the Routech Ergon CNC Router,

a highly productive

router that offers

plastic fabricators a

high degree of manufacturing

flexibility.

Perfect for nesting or fabricating or any close tolerance precision plastic parts,

the router comes standard with high quality aluminum

grid tables that offer the industries’ best vacuum hold

down. The Ergon is equipped with powerful 15 hp liquid

chilled electro spindles (variable speeds from 900 to

18,000 RPM) and an on-board 12-position automatic tool

changers. A variety of table sizes are available (twin 5’ x

5’, 5’ x 10’, etc.) with two to four router heads. The Ergon

is also available with independent X-axis CNC Control

which allows simultaneous processing of different parts on

opposite tables at the same time.

router that offers

plastic fabricators a

high degree of manufacturing

flexibility.

Perfect for nesting or fabricating or any close tolerance precision plastic parts,

the router comes standard with high quality aluminum

grid tables that offer the industries’ best vacuum hold

down. The Ergon is equipped with powerful 15 hp liquid

chilled electro spindles (variable speeds from 900 to

18,000 RPM) and an on-board 12-position automatic tool

changers. A variety of table sizes are available (twin 5’ x

5’, 5’ x 10’, etc.) with two to four router heads. The Ergon

is also available with independent X-axis CNC Control

which allows simultaneous processing of different parts on

opposite tables at the same time.

CNC Machining Center

The Author 600 CNC NBM is a versatile

machining center with the capability of

bringing 3-shift a day quality and reliability

to the plastic distributor

and fabricator.

and fabricator.

The machine includes

a high quality

5’ x 10’ aluminum

grid vacuum table, a

15 hp liquid chilled electrospindle with a 12-position “on

board tool changer”. The drill head features 18 vertical

spindles and 2+2+1+1 horizontal boring.

For additional information, contact Phil Bryant, SCM

Group USA Inc., 2475 Satellite Blvd., Duluth, GA 30096,

770-813-8818, Fax: 770-813-8819, E-mail: pbryant@scmgroup-usa.com, Web: www.scmplastics.com.

IWF

Booth #s 8326, 8340

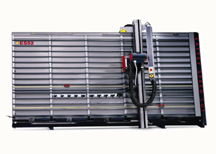

Vertical Panel

Saws

Safety Speed Cut manufactures

a complete range of vertical

panel saws for processing a wide

variety of panelized

materials such

as plastic, metal, wood and composites.

Their Model ES52 is well

suited for those demanding high

volume production environments

with tight tolerance requirements.

materials such

as plastic, metal, wood and composites.

Their Model ES52 is well

suited for those demanding high

volume production environments

with tight tolerance requirements.

With nearly 50 years of experience

since first developing their

vertical sawing concept, Safety

Speed Cut consistently delivers accurate, well built panel

sizing equipment that will improve the efficiency and safety

of your business.

For additional information, contact Tom Houska, Safety

Speed Cut Mfg., 13943 Lincoln Street N.E., Hamlake, MN

55304, 800-772-2327/763-755-1600, E-mail: sales@

safetyspeedcut.com, Web: www.safetyspeedcut.com.

IWF

Booth #5753

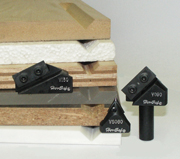

Screw-On Insert V-Cutters

Her-Saf Screw-On Insert

V-Cutters are plunging

into different materials

everyday. They are available

from 60º to 170º

angles in both body styles:

small for machines with

1/4”or smaller collets, and

the standard size for 1/2”

collets and larger. The custom ground v-insert removes the

need for sharpening while adding the bonus of maintaining

the point. Balanced to run at speeds up to 21,000

rpm while maintaining a clean accurate cut. The Screw-On

style cutter preserves the original setup when having to

put a new insert in place. The V-Cutters are now being

used successfully by the sign industry, packaging industry

and decorative wood and plastic industry.

small for machines with

1/4”or smaller collets, and

the standard size for 1/2”

collets and larger. The custom ground v-insert removes the

need for sharpening while adding the bonus of maintaining

the point. Balanced to run at speeds up to 21,000

rpm while maintaining a clean accurate cut. The Screw-On

style cutter preserves the original setup when having to

put a new insert in place. The V-Cutters are now being

used successfully by the sign industry, packaging industry

and decorative wood and plastic industry.

For additional information, contact Linda Wyant,

Safranek Enterprises Inc., 4005 El Camino Real, Atascadero

CA 93422, 800-553-9344, E-mail: sales@hersaf.com, Web: www.hersaf.com.

IWF Booth #5964.

Panel Saw for Plastics

Schelling’s FMK panel

saw is designed and

engineered for high

speed, precision cutting

of plastic panels including

acrylic, PETG, polycarbonate,

polyolefins, PVC,

UHMW, phenolicls, mechanical and other specially engineered

materials. The FMK provides extremely tight cutting

tolerances, chip free cutting of material as thin as

.030” without a cover board and produces glassy smooth

finishes that eliminates the need for secondary machining.

speed, precision cutting

of plastic panels including

acrylic, PETG, polycarbonate,

polyolefins, PVC,

UHMW, phenolicls, mechanical and other specially engineered

materials. The FMK provides extremely tight cutting

tolerances, chip free cutting of material as thin as

.030” without a cover board and produces glassy smooth

finishes that eliminates the need for secondary machining.

Features include; rigid heavy duty construction; stateof-

the-art material handling technology automating loading,

cutting and off loading processes; on-line remote

diagnostics for increased uptime and productivity; spindle

speed control combined with a patented blade design;

solid pressure beam with dust protection curtain for dust

free parts; online downloading of optimized cutting patterns

and label printing. The FMK is offered at a very

attractive price to fit the budgets of manufacturers and

fabricators of various sizes.

For additional information, contact Stephen Bailey,

Schelling America, Inc., P.O. Box 80367, Raleigh, NC

27623, 919-544-0430, Fax: 919-544-0920. E-mail:

sbailey@schelling.com, Web: www.schelling.com.

IWF

Booth #8840

CNC Machining Center

The Balestrini Idea, from

Solid Wood

Systems,

combines speed and

accuracy in a compact CNC

machining center. Ideal for

both small and large production

runs, the Idea features

fully digital controls

with drives by NUM. It is

single fixturing insures

multiple operation accuracy

with high part output

while requiring only a single operator.

fully digital controls

with drives by NUM. It is

single fixturing insures

multiple operation accuracy

with high part output

while requiring only a single operator.

CNC Band Saw

The MZ Project Band Sawing Center combines a 3-axis

CNC band saw with a CC point-to-point boring unit to

deliver the fastest and most efficient method for cutting

and boring sheet plastics and panels. Bandsawing is much

faster than routing and significantly reduces waste.

For additional information, contact Paul Green, Solid

Wood Systems, Inc., 3202 East Kivett Drive, High Point,

NC 27260, 336-884-0700, Fax: 336-887-6650, E-mail:

swsmachine@aol.com, Web: www.solidwoodsystems.com.

IWF Booth #6072

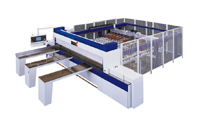

Solutions for Plastic and

Composites

Stiles Machinery Inc. announced they will display solutions

designed exclusively for plastic and composite

materials in booth #9140 at IWF 2006. The Stiles exhibit

will include the following machines for plastic applications:

Holzma HPP 380P: For plastic and composite cutting,

the saw features a variable speed main saw

motor that

enables selection of best blade rim speed and cutting

speed.

motor that

enables selection of best blade rim speed and cutting

speed.

Weeke BHP 200P: This

CNC router is designed

for individual part processing

or full sheet

routing.

It is equipped

with an 8-position tool

changer, an oversized 5’ x

12’ table, and a 12 hp, 24,000 rpm router motor that can

handle all types of plastic and composite materials.

It is equipped

with an 8-position tool

changer, an oversized 5’ x

12’ table, and a 12 hp, 24,000 rpm router motor that can

handle all types of plastic and composite materials.

Belotti Milling Machines: Extremely versatile CNC

milling machines suitable for many applications. These 3-

and 5-axis machines are designed to simplify

the manufacturing of parts with complex

shapes while delivering

the highest performance

of speed and precision.

Heian FP-151: 5-axis CNC router designed for trimming

and machining plastics and composite materials. Featuring

a constant output 3.7 kW spindle positioned

on a fixed, overhead bridge, the

FP-151 provides tight tolerances

with excellent cut quality.

For additional information,

contact Bill Pitt, Stiles Machinery

Inc., 3965 44th St.

SE, Grand Rapids, MI 49512,

616-698-7500, Fax: 616-698-

9411, E-mail: bpitt@stilesmachinery.com, Web:

www.stilesmachinery.com.

IWF Booth #s 9006, 9026,

9040, 9062. 9106, 9126, 9140, 9226, 9240,

9262, also see them at SPE Booth #421

Radius O Flutes

Southeast Tool, Inc. is

offering a new solid carbide

2 flute radius O flute

for plastic cutting. The company

states that the benefit of the two flute tool is better

edge finish. This is especially true on problem type materials.

In addition, the O flute design helps in the chip curl

to keep the chips from rewelding to the part that is cut.

The tool is available in 3 sizes now, with more sizes

planned in the very near future.

2 flute radius O flute

for plastic cutting. The company

states that the benefit of the two flute tool is better

edge finish. This is especially true on problem type materials.

In addition, the O flute design helps in the chip curl

to keep the chips from rewelding to the part that is cut.

The tool is available in 3 sizes now, with more sizes

planned in the very near future.

For additional information, contact Chuck Hicks,

Southeast Tool, Inc., P.O. Box 1597, Conover, NC 28613,

828-465-7012, Fax: 828-465-7013, E-mail: router@

southeasttool.com, Web: www.southeasttool.com.

IWF

Booth #4753

Expanded Product Line

A new 40-page catalog from

Vortex Tool Company, Inc. provides

an overview of more than 400

different types of tools the company

designs and manufactures for the

woodworking and plastics industries.

The catalog includes several new

lines of router bits designed for cutting

Phenolic materials, and additional

tooling is featured for cutting aluminum and several

new configurations of fiberglass. Vortex has also complemented

existing tool lines by adding numerous new tooling

choices including several sizes in metrics.

an overview of more than 400

different types of tools the company

designs and manufactures for the

woodworking and plastics industries.

The catalog includes several new

lines of router bits designed for cutting

Phenolic materials, and additional

tooling is featured for cutting aluminum and several

new configurations of fiberglass. Vortex has also complemented

existing tool lines by adding numerous new tooling

choices including several sizes in metrics.

For additional information, contact Mike Serwa, Vortex

Tool Company, 5605 Jelinek Avenue, Schofield, WI

54476, 800-355-7708, Fax: 715-355-7353, Web:

www.vortextool.com.

IWF Booth #9049

|